Integrated membrane processing technology for purifying and regenerating spent lubrication oil

A waste lubricating oil and membrane treatment technology, applied in the direction of lubricating compositions, etc., can solve the problems of complex process, long process, high energy consumption, etc., and achieve the effect of simple process, improved efficiency, and improved membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

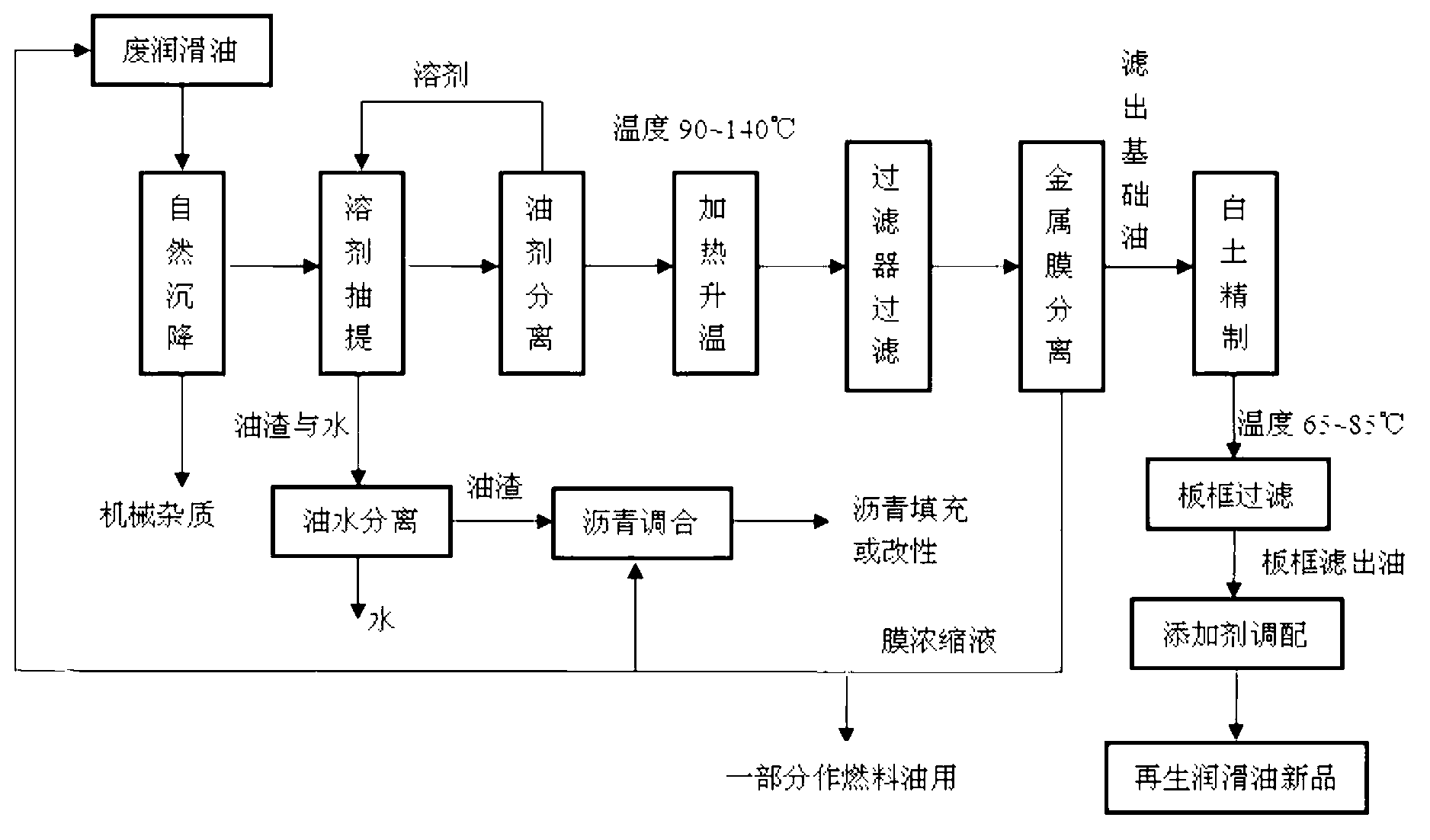

[0038] Such as figure 1 As shown, a membrane treatment integrated process for purifying and regenerating waste lubricating oil specifically includes the following steps:

[0039] (1) put 5m 3 The waste lubricating oil of / h processing capacity is heated and naturally settled, and the temperature is raised to 40°C, and the settling time is about 24 hours (removal of sediment, that is, mechanical removal of impurities);

[0040] (2) Use propane in the solvent extraction tower to carry out solvent extraction treatment on the waste lubricating oil after natural sedimentation. The process parameters of solvent extraction are: the solvent-oil ratio is 3:1, the temperature is 40°C, and the pressure is about 4MPa. Solvent extraction mixture, oil residue and water are obtained, and the oil residue is dehydrated and blended with asphalt to obtain asphalt blending material, which is then developed as road asphalt;

[0041] (3) Separate the extraction mixture from the previous step in t...

Embodiment 2

[0049] In this embodiment, a membrane treatment integration process for purifying and regenerating waste lubricating oil is roughly the same as in Embodiment 1, except that:

[0050] (1) put 5m 3 The waste lubricating oil of the / h treatment capacity is heated and naturally settled, and the temperature is raised to 60°C, and the settling time is about 12 hours;

[0051] (2) The process parameters of solvent extraction are: the solvent-oil ratio is 5:1, the temperature is 60°C, and the pressure is about 4MPa;

[0052] (3) During the oil separation process, the temperature for distilling the organic solvent is 120°C and the pressure is 2.0Mpa;

[0053] (4) Heating the waste lubricating oil obtained after oil separation, and the temperature after heating is 110°C;

[0054] (5) The main parameters of the metal filter are controlled as follows: oil inlet pressure 0.5MPa, waste lubricating oil temperature 110°C, oil inlet flow 4m 3 / h;

[0055] (6) The main parameters of the met...

Embodiment 3

[0059] In this embodiment, a membrane treatment integration process for purifying and regenerating waste lubricating oil is roughly the same as in Embodiment 1, except that:

[0060] (1) put 5m 3 The waste lubricating oil of the / h treatment capacity is heated and naturally settled, and the temperature is raised to 80°C, and the settling time is about 4 hours;

[0061] (2) The process parameters of solvent extraction are: the solvent-oil ratio is 7:1, the temperature is 80°C, and the pressure is about 4MPa;

[0062] (3) During the oil separation process, the temperature for distilling the organic solvent is 150°C and the pressure is 2.0Mpa;

[0063] (4) Heating the waste lubricating oil obtained after oil separation, and the temperature after heating is 130°C;

[0064] (5) The main parameters of the metal filter are controlled as follows: oil inlet pressure 0.3MPa, waste lubricating oil temperature 130°C, oil inlet flow 4m 3 / h;

[0065] (6) The main parameters of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com