Beam and slab integrally casted building template

It is a technology of integral casting and building formwork, which is used in construction, building structure, formwork/formwork components, etc. It can solve the problems of small combined steel formwork blocks, low recycling rate, and low construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

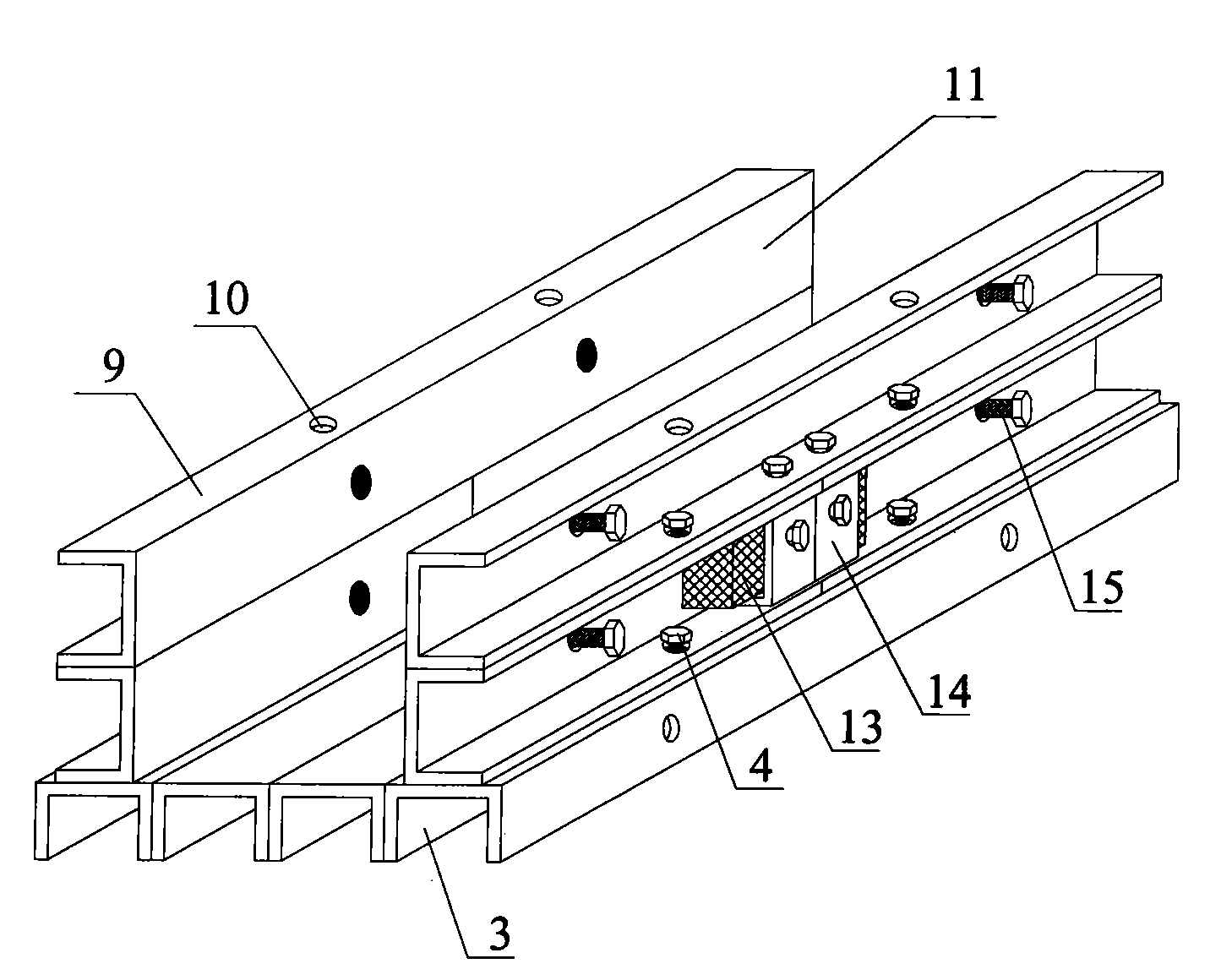

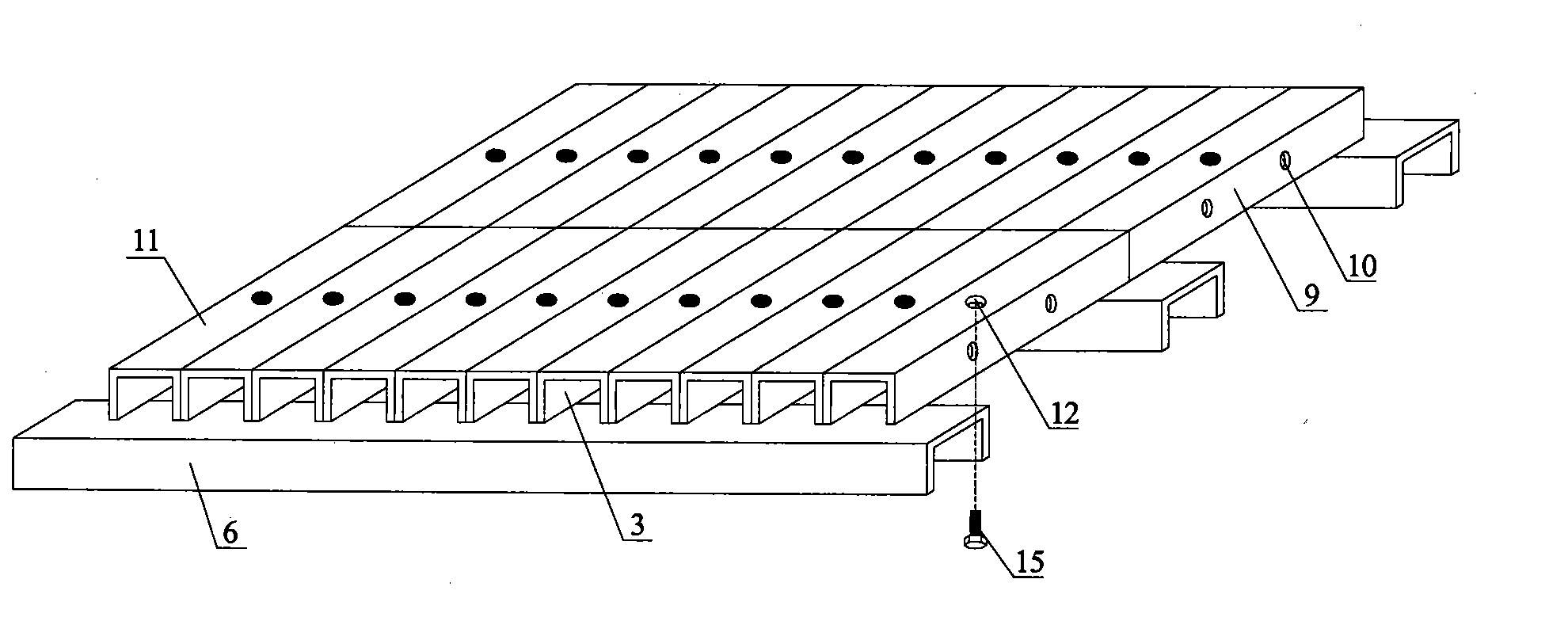

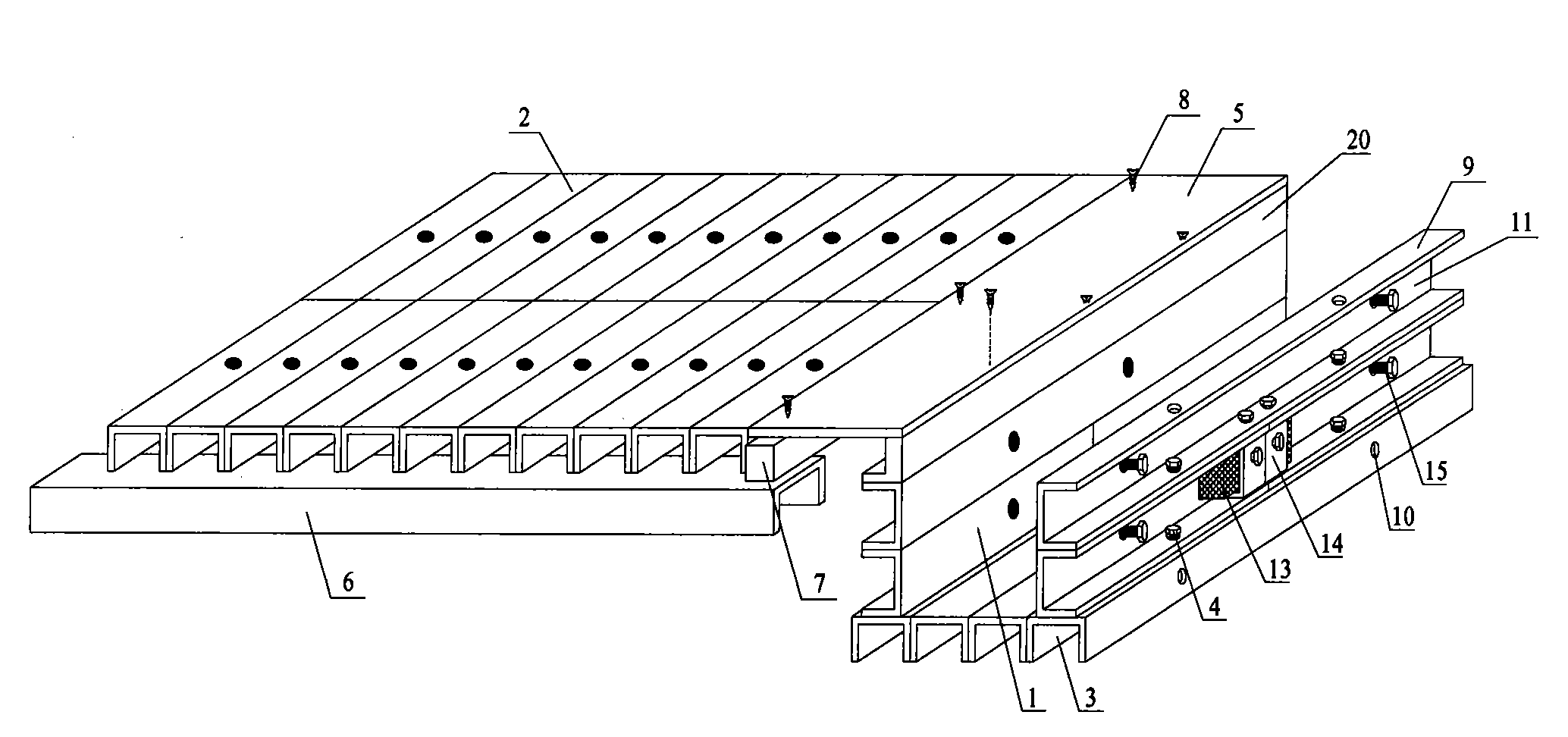

[0022] The invention is attached Figure 1-9 As shown, a beam and slab integral pouring building formwork includes a beam formwork 1 and a slab formwork 2. Both the beam formwork 1 and the slab formwork 2 are assembled by a plurality of trough-shaped modules 3 connected to each other, and the trough-shaped modules 3 pass through The bolt 4 is connected, and the bottom of the plate formwork 2 is supported by a support beam 6. The feature of the present invention is that the joint between the plate formwork 2 and the beam formwork 1 is provided with a cover plate 5, and there are pads 7 on the support beam 6 at the bottom of the plate formwork 2. , There is a backing plate 20 on the top of the beam template 1, one end of the cover plate 5 is supported on the pad strip 7, and the other end is supported on the backing plate 20. The trough-shaped module 3 includes a web 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com