Hollow slab template for buildings

A technology for hollow floor slabs and buildings. It is applied in the direction of construction, building structure, formwork/formwork/working frame, etc. It can solve the problems of low rigidity, low recycling rate, poor integrity and stability of side formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

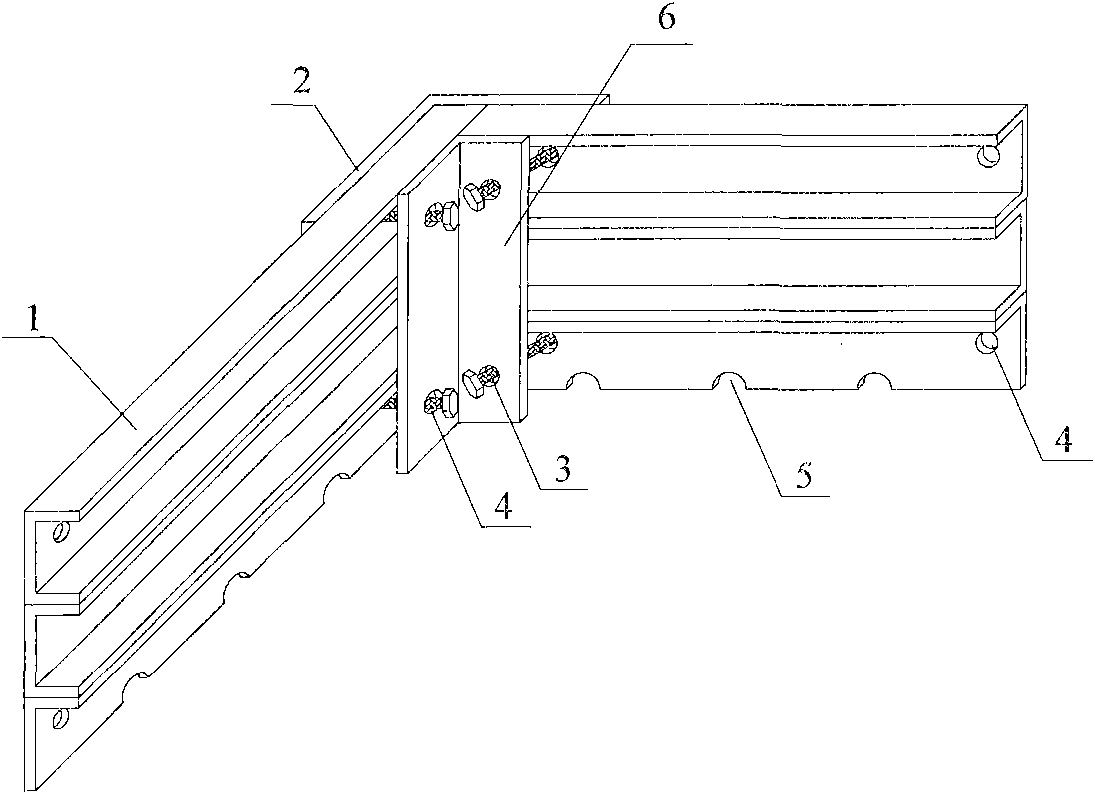

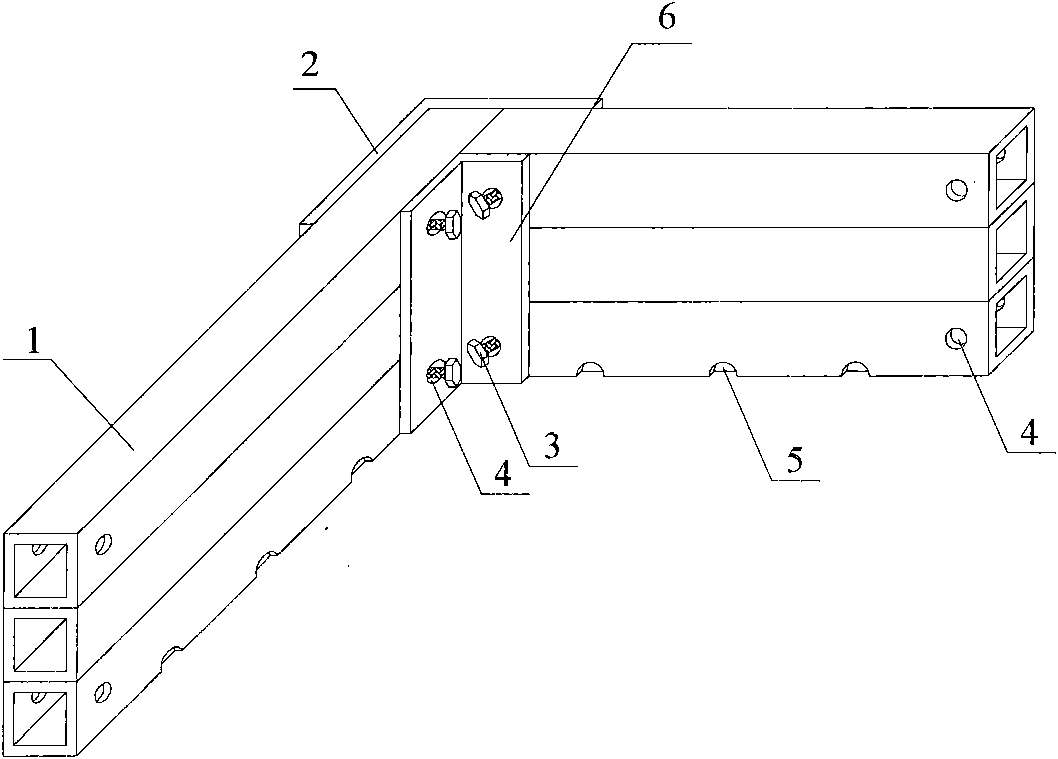

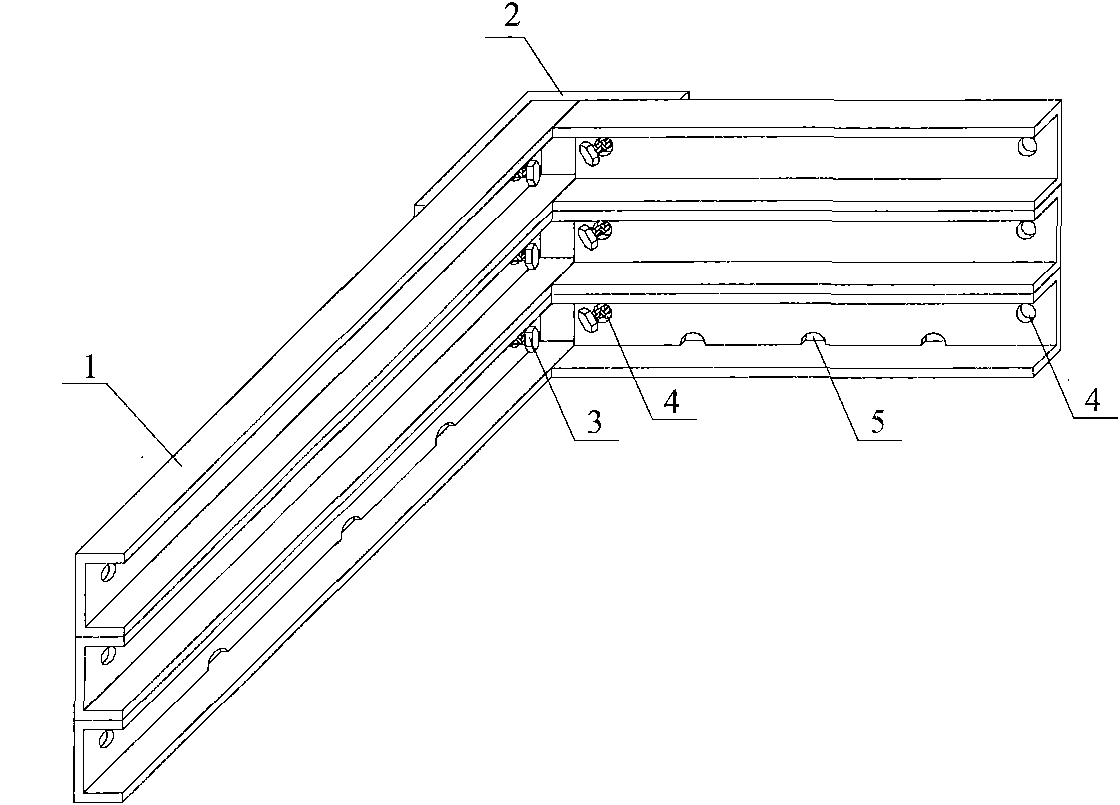

[0021] The present invention will be further described below in conjunction with the drawings.

[0022] The invention is attached Figure 1~8 As shown, a hollow floor formwork for construction, the hollow floor formwork includes a module 1, a corner form 2, bolts 3 or bolts and other connecting parts, a prefabricated bottom plate 9, and the hollow floor formwork has two bottom-most modules 1 Or more than two holes or gaps5. Support ribs 10 can be implanted in the holes or gaps 5 on the module 1. After the cast-in-place concrete 11 of the hollow floor slab is poured and reaches a certain strength, the formwork is removed, and the prefabricated floor 9 is placed on the support ribs 10 to make the prefabricated floor 9 is connected with the rib beam, and the crack resistance of the prefabricated floor 9 is improved, and the integrity of the hollow floor slab is enhanced.

[0023] The hollow floor formwork is assembled by two or more modules 1, and the modules 1 are connected by corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com