Hydraulic system of orchard picking equipment

A hydraulic system and equipment technology, applied in the field of orchard machinery and equipment, can solve the problems of low efficiency, high picking cost, low picking efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

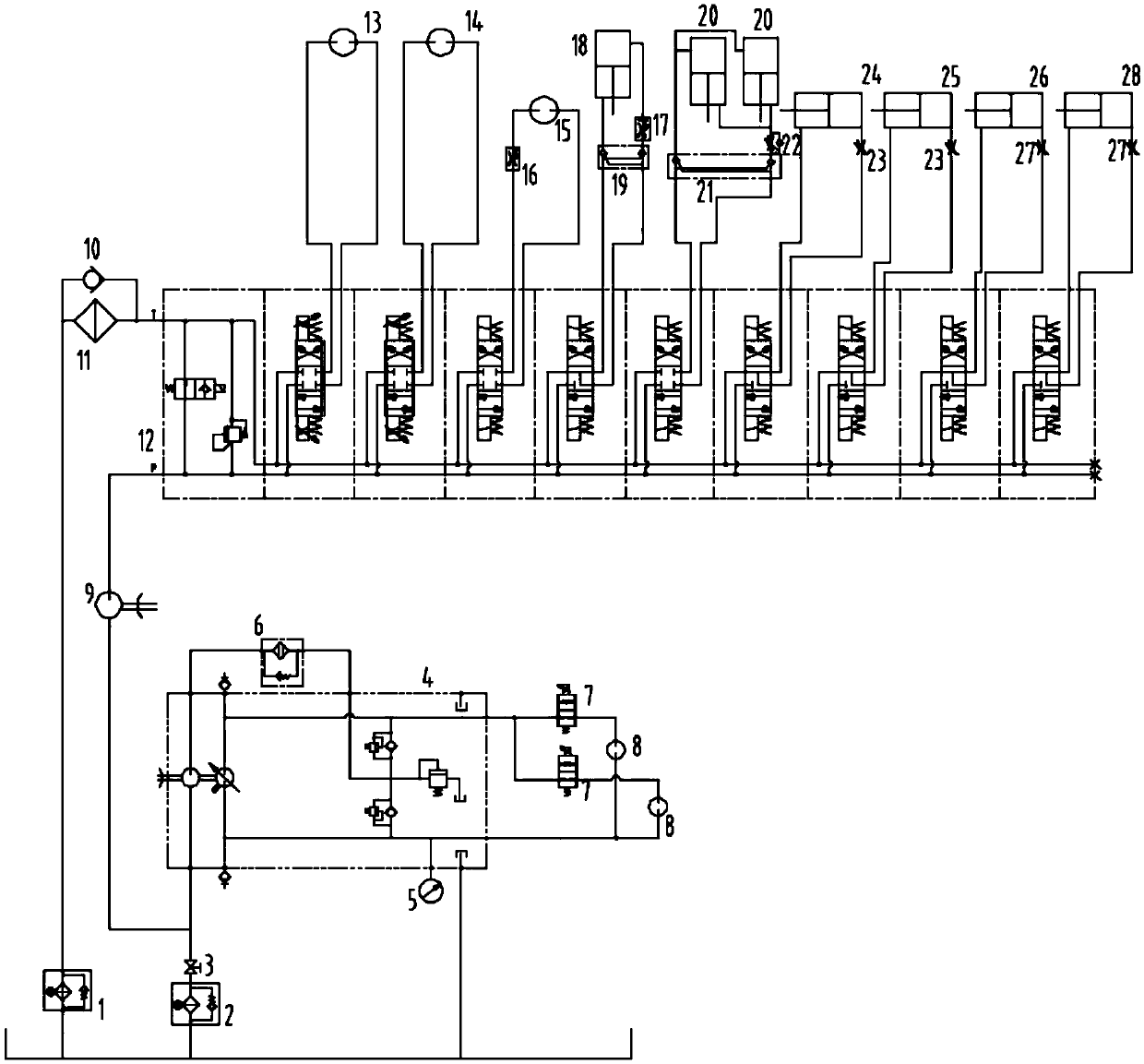

[0027] A hydraulic system for orchard picking equipment, including oil suction pipeline, oil return pipeline, variable pump 4, high pressure filter 6, proportional flow valve 7, travel motor 8, quantitative pump 9 and multi-way valve 12, high pressure filter 6 and variable The pressure outlet of the pump 4 is connected, and there are two proportional flow valves 7, which are respectively connected to the left and right sides of the travel motor 8, and control the oil supply of the left and right travel motor 8. The variable pump 4 is equipped with a pressure gauge 5 and a quantitative pump 9. Provide pressure oil for the bodywork conveying system and chassis steering system; a cooler 11 is installed on the oil return pipeline;

[0028] The multi-way valve 12 is a nine-way multi-way valve; the nine-way multi-way valve is connected to the outlet of the quantitative pump 9, and the pressure is provided by the quantitative pump 9. The multi-way valve 12 respectively controls a sta...

Embodiment 2

[0043] A hydraulic system for orchard picking equipment, including oil suction pipeline, oil return pipeline, variable pump 4, high pressure filter 6, proportional flow valve 7, travel motor 8, quantitative pump 9 and multi-way valve 12, high pressure filter 6 and variable The pressure outlet of the pump 4 is connected, and there are two proportional flow valves 7, which are respectively connected to the left and right sides of the travel motor 8, and control the oil supply of the left and right travel motor 8. The variable pump 4 is equipped with a pressure gauge 5 and a quantitative pump 9. Provide pressure oil for the upper loading conveying system and chassis steering system of the orchard picking equipment; a cooler 11 is installed on the oil return pipeline;

[0044] The multi-way valve 12 is a nine-way multi-way valve; the nine-way multi-way valve is connected to the outlet of the quantitative pump 9, and the pressure is provided by the quantitative pump 9. The multi-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com