Hydrogen sulfide resistant stainless steel forge piece for oil exploitation operation and preparation method of hydrogen sulfide resistant stainless steel forge piece

A technology for oil extraction and resistance to hydrogen sulfide, which is applied in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve problems such as product standards that have not yet been formulated, and achieve improved anti-corrosion performance, improved welding performance and cold bending. performance, the effect of improving toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

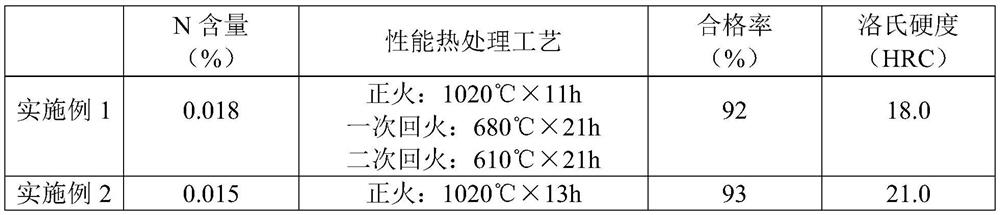

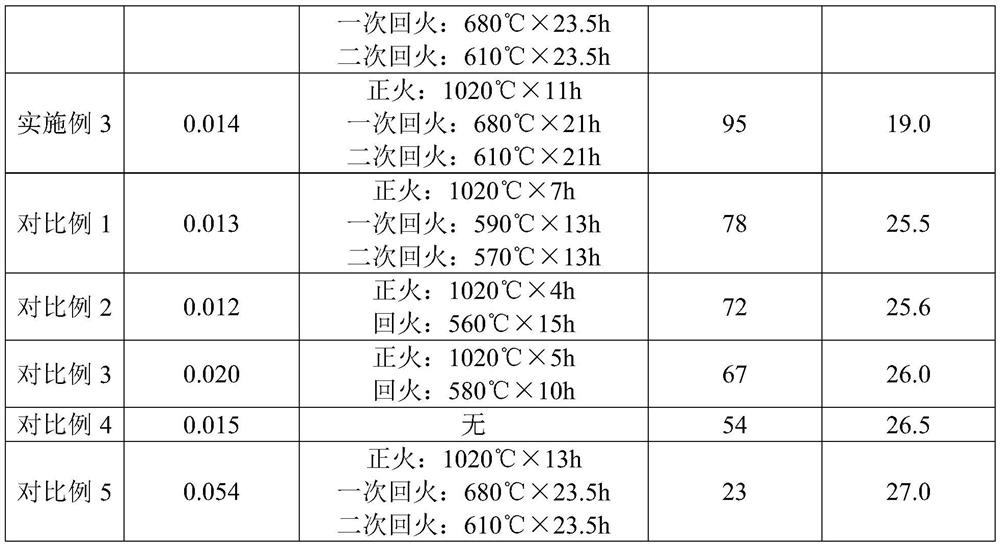

Examples

Embodiment 1

[0057] (1) Raw material procurement: purchase F6NM stainless steel ingots as raw materials;

[0058] (2) Performance testing: Carry out re-testing of chemical composition of raw materials, take qualified products as raw materials, the weight percentage of each element component in raw materials is: C: 0.015%, Si: 0.45%, Mn: 0.56%, P: 0.022 %, S: 0.001%, Ni: 3.80%, Cr: 12.30%, Mo: 0.54%, N: 0.018%, Al: 0.005%, Cu: 0.06%, Co: 0.065%, and the balance is Fe;

[0059] (3) Forging:

[0060] Take the raw materials that have passed the re-inspection in step (2) and carry out the first fire forging. The first fire forging process is: the initial forging temperature is 1160 ° C, the final forging temperature is 800 ° C, upsetting and elongation are carried out, and the upsetting ratio is 2 , the drawing length ratio is 2, upsetting, chamfering, punching, rounding, reaming treatment, mandrel drawing, correcting and forming, and the forging billet is obtained;

[0061] (4) Heat treatmen...

Embodiment 2

[0070] (1) Raw material procurement: purchase F6NM stainless steel ingots as raw materials;

[0071] (2) Performance testing: Carry out re-inspection of chemical composition of raw materials, take qualified products as raw materials, the weight percentage of each element component in raw materials is: C: 0.012%, Si: 0.4%, Mn: 0.60%, P: 0.024 %, S: 0.005%, Ni: 3.80%, Cr: 12.35%, Mo: 0.52%, N: 0.015%, Al: 0.008%, Cu: 0.09%, Co: 0.07%, and the balance is Fe;

[0072] (3) Forging:

[0073] Take the raw materials that pass the re-inspection in step (2) for the first fire forging, the first fire forging process is: initial forging temperature 1160 ° C, final forging temperature 850 ° C, upsetting and elongation, upsetting ratio 2.5 , the pull-out ratio is 2.5;

[0074] Put it in a furnace at 1160°C and heat it for 2.2 hours, then carry out the second fire forging. The second fire forging process is: initial forging temperature 1160°C, final forging temperature 850°C, upsetting, ch...

Embodiment 3

[0085] (1) Raw material procurement: purchase F6NM stainless steel ingots as raw materials;

[0086] (2) Performance testing: Carry out re-inspection of chemical composition of raw materials, take qualified products as raw materials, the weight percentage of each element component in raw materials is: C: 0.014%, Si: 0.47%, Mn: 0.69%, P: 0.022 %, S: 0.006%, Ni: 3.82%, Cr: 12.25%, Mo: 0.53%, N: 0.014%, Al: 0.006%, Cu: 0.08%, Co: 0.065%, and the balance is Fe;

[0087] (3) Forging:

[0088] Take the raw materials that pass the re-inspection in step (2) and carry out the first fire forging. The first fire forging process is: the initial forging temperature is 1160 ° C, the final forging temperature is 900 ° C, upsetting and elongation are carried out, and the upsetting ratio is 3 , the draw ratio is 3;

[0089] Place it in a furnace at 1160°C for heating, keep it warm for 2.5 hours, and perform the second fire forging. The second fire forging process is: initial forging temperat...

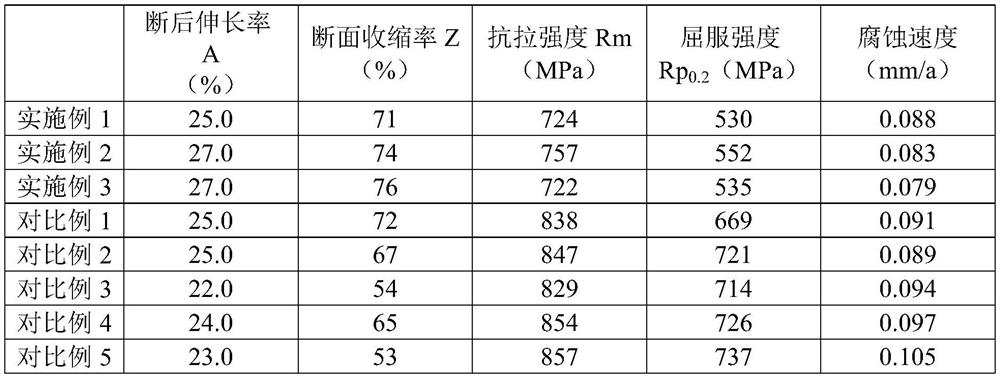

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com