Cutting trimming device of conveyer belt

A trimming machine and conveyor belt technology, which is applied in transportation and packaging, metal processing, coiling strips, etc., can solve problems such as low work efficiency, high labor intensity, poor cutting and trimming quality, and achieve convenient operation and reduce Labor intensity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

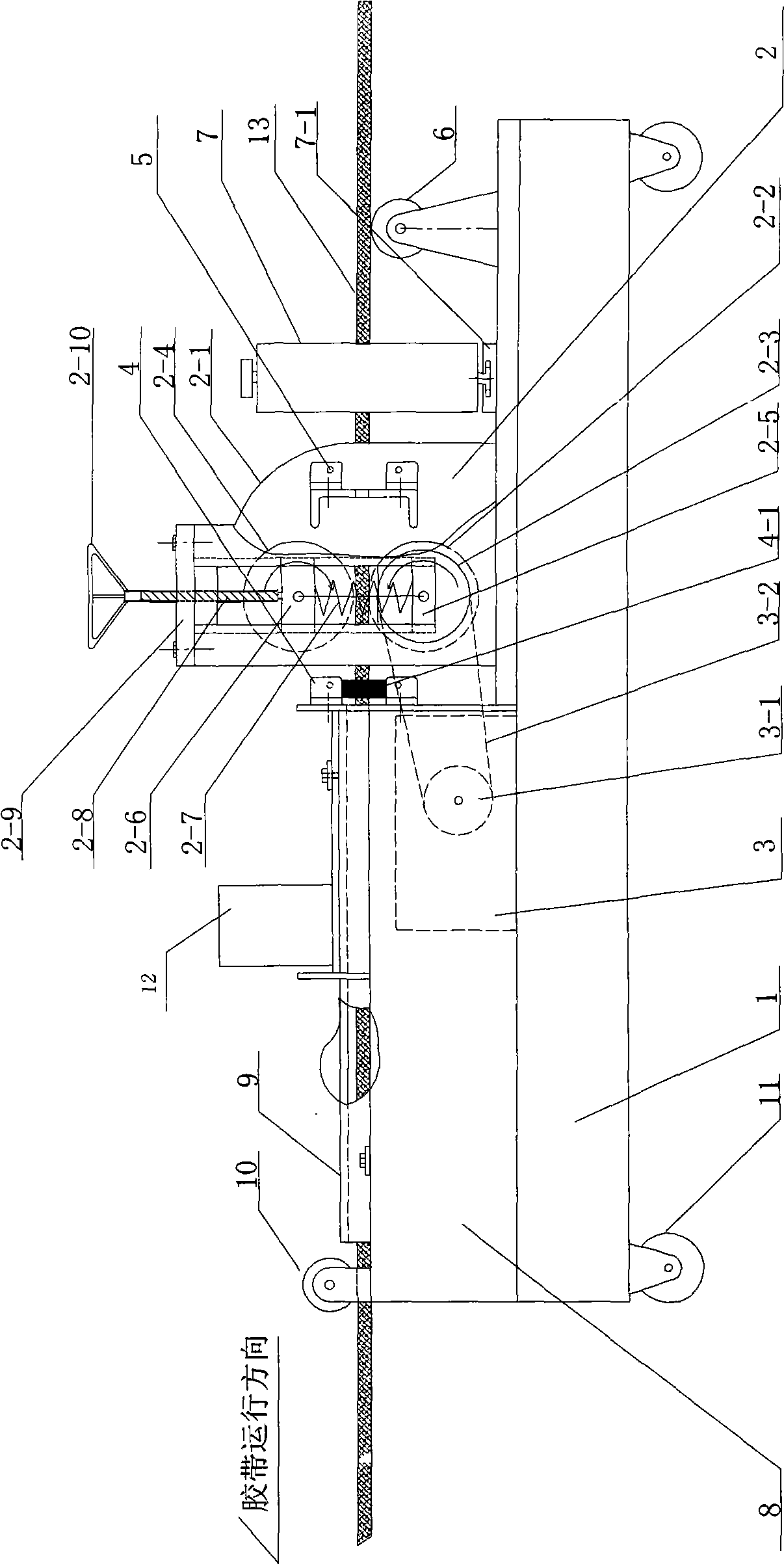

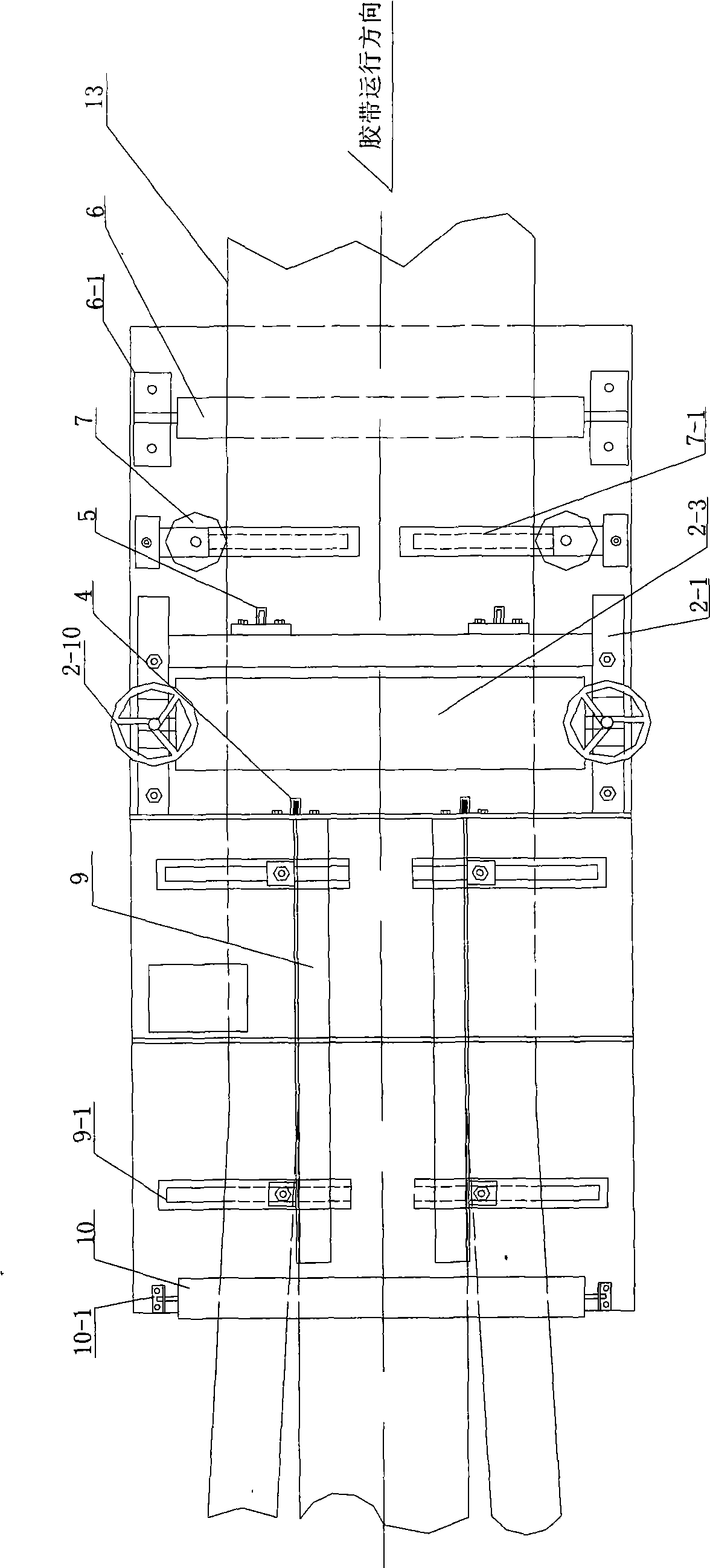

[0018] The implementation process of the present invention is described in detail in conjunction with the accompanying drawings.

[0019] Such as figure 1 , figure 2 , as shown in Figure 3;

[0020] The base 1 is made of cast iron or welded parts, and the two column supports 2-1 are made of cast iron or welded parts. Walking wheels 11 are installed on the bottom surface.

[0021] Drive device 3 is made of motor and gearbox, and is installed on the base 1, and sprocket 3-1 is installed on the output shaft of gearbox.

[0022] The guide groove is processed on the column support 2-1, and its width matches the fixed bearing seat 2-5 and the moving bearing seat 2-6; the fixed bearing seat 2-5 and the moving bearing seat 2-6 are square or rectangular in shape type, the inner hole matches the bearing outer ring on the belt-feeding drive roller 2-2 and the belt-feeding pressure roller 2-3; the size and shape of its two sides match the guide groove of the column bracket 2-1; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com