Shale shakers

a shaker and shale technology, applied in the direction of filtration separation, separation process, moving filter element filter, etc., can solve the problems of deterioration of steel parts, wear, erosion, rust and corrosion of steel, etc., and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

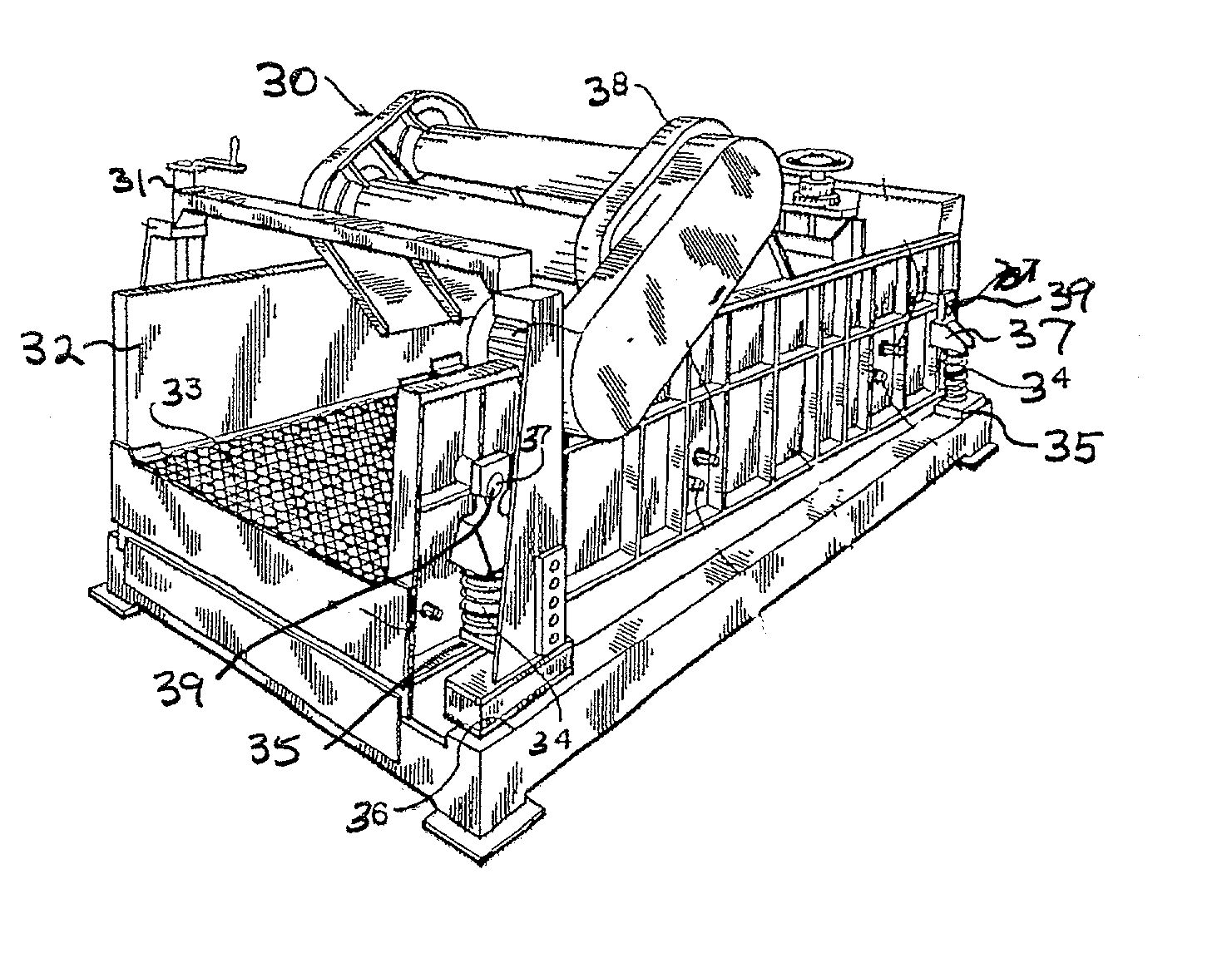

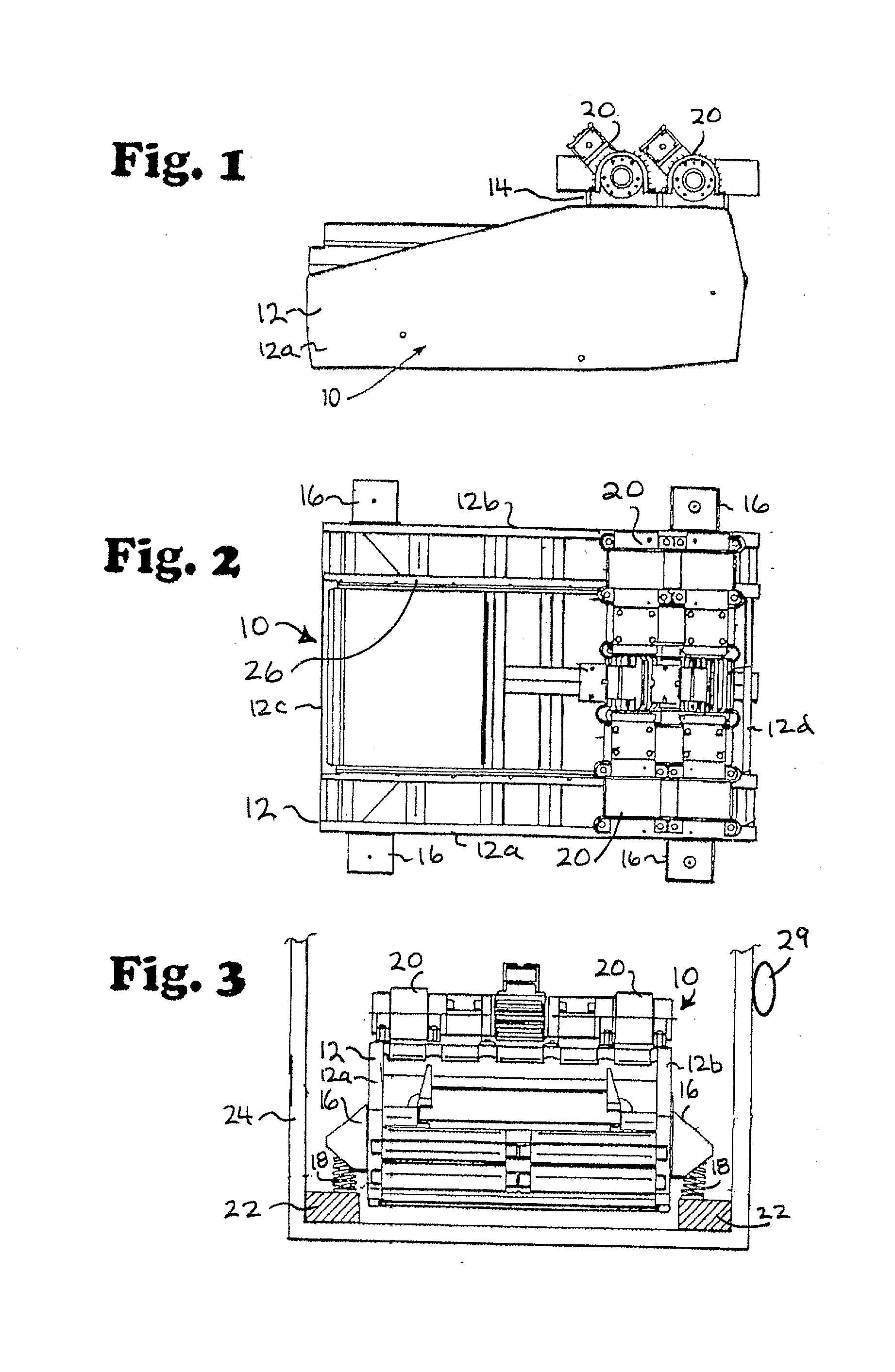

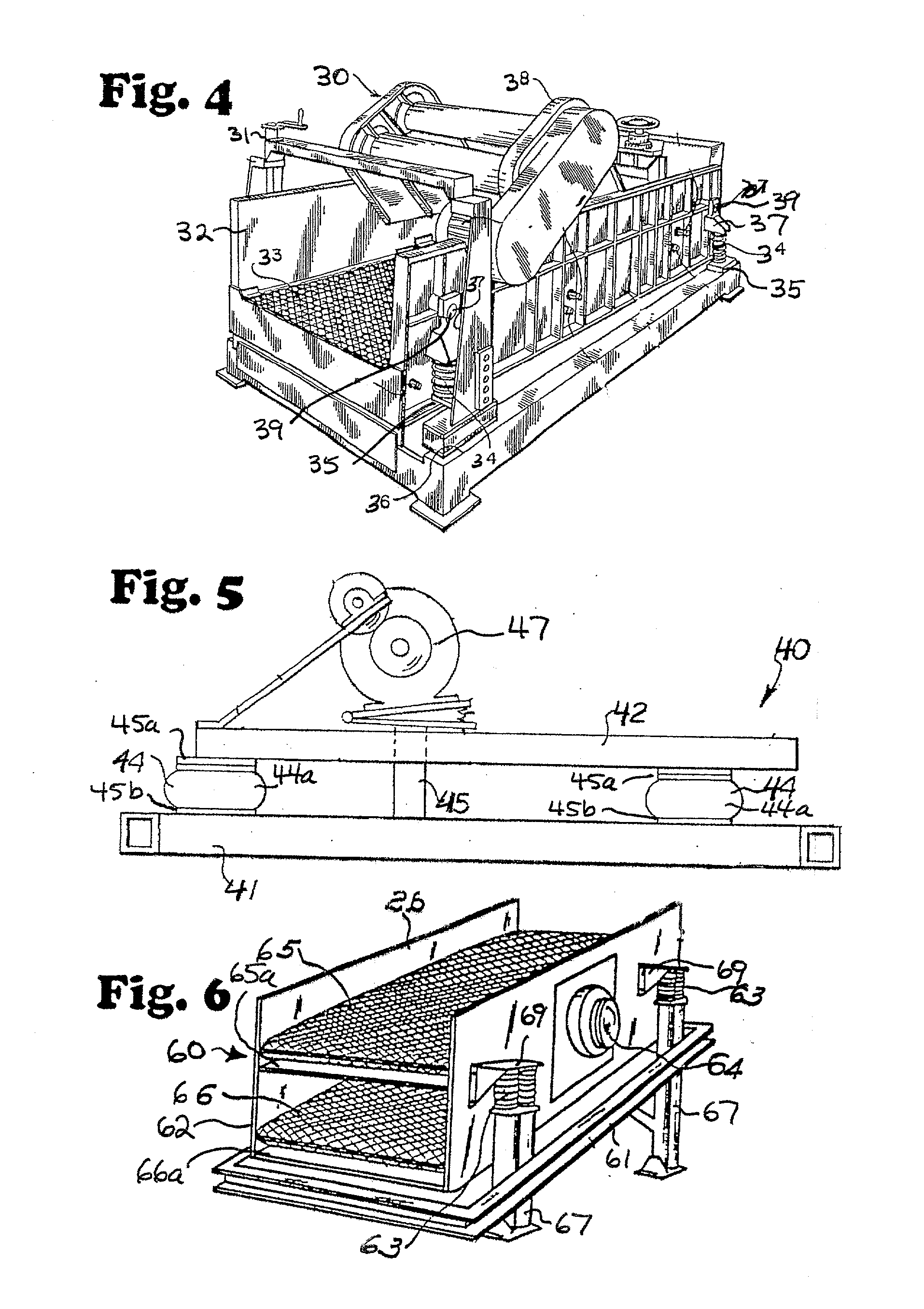

[0033] FIGS. 1-3 show a shale shaker 10 according to the present invention which has a screen-mounting basket 12 and a bridge 14 on which are mounted two vibrating apparatuses 20. The basket 12 has brackets 16 to which are secured helical springs 18. Each spring 18 is secured to a base member 22. As shown in FIG. 3, an optional housing 24 may be used on sides of and beneath the shale shaker 10. Optionally (and as may be the case with any shale shaker disclosed herein according to the present invention or with any known prior art shaker or vibratory separator) an electronic tracking apparatus 29 is on the housing 24, but may, according to the present invention, be within any suitable member or part of a shale shaker; and, optionally, such a tracking apparatus has a container or housing made of composite material and / or is encased within or coated with composite material. Any known tracking device, apparatus, or system may be used, including, but not limited to known satellite trackin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com