Adhesive for black rubber shoe topline sponges as well as preparation method and application of adhesive

A kind of adhesive and black technology, which is applied in the direction of natural rubber adhesive, adhesive, adhesive type, etc., can solve the problems affecting the appearance quality and production efficiency of the heel of rubber shoes, and the deviation of the positioning and sewing of composite heel cloth, etc., to achieve Improve sewing speed and production efficiency, increase production efficiency, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

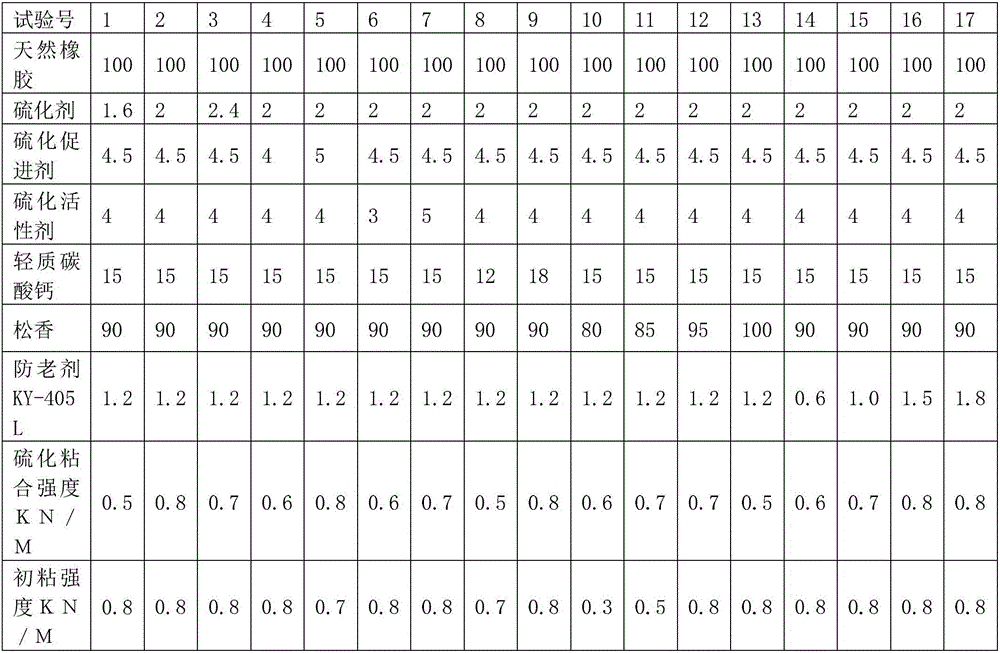

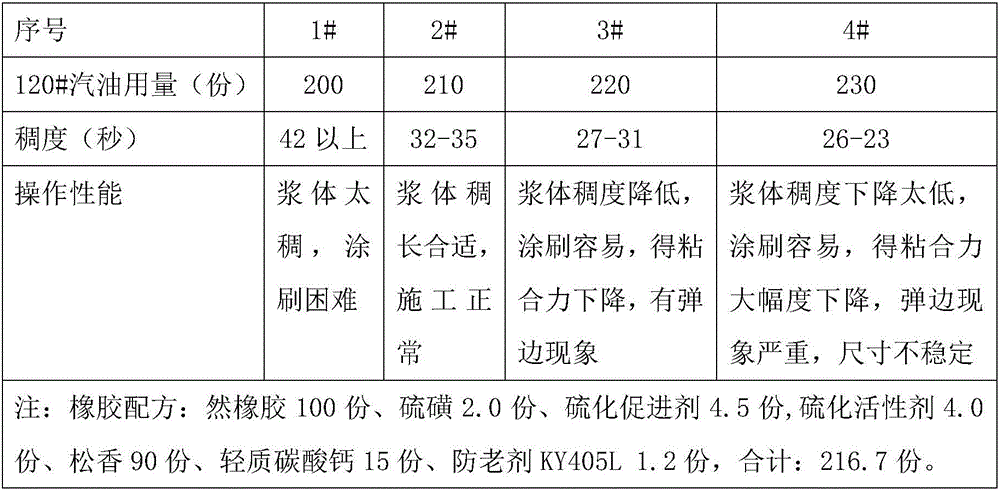

[0049] Embodiment 1 of the present invention: rubber shoes black mouth sponge adhesive, calculated by weight, it includes 100 parts of natural rubber, 2.0 parts of sulfur, 4.5 parts of vulcanization accelerator, 4.0 parts of vulcanization activator, 90 parts of rosin, light 15 parts of calcium carbonate, 1.2 parts of anti-aging agent KY-405L and 210 parts of 120# gasoline are the raw materials for preparation; among them, every 4.5 parts of vulcanization accelerator is composed of 1.8 parts of accelerator M, 2.2 parts of accelerator DM and 0.5 parts of accelerator DS ; Every 4 parts of vulcanization activator is composed of 3.5 parts of active zinc oxide and 0.5 parts of stearic acid.

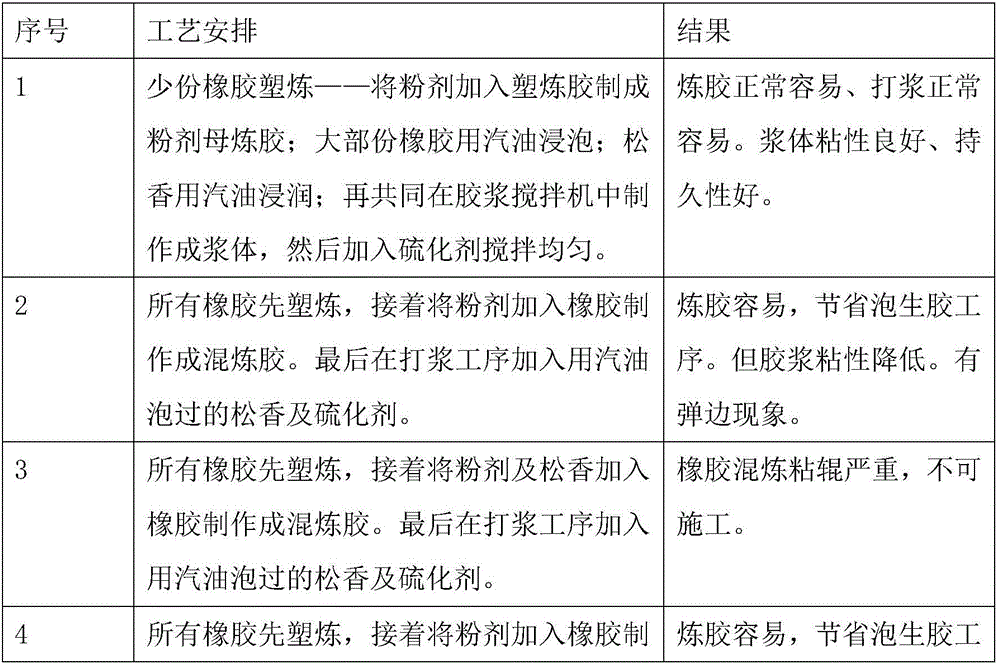

[0050] The preparation method of rubber shoes black mouth sponge adhesive, each component is taken by the above-mentioned parts by mass, comprises the steps:

[0051] 1) Making natural rubber mastication: take 10 parts of natural rubber on an open-type rubber mixing machine, pass through the ma...

Embodiment 2

[0057] Embodiment 2 of the present invention: rubber shoes black mouthpiece sponge adhesive, calculated by weight, it includes 100 parts of natural rubber, 2.0 parts of sulfur, 4.5 parts of vulcanization accelerator, 4.0 parts of vulcanization activator, 90 parts of rosin, light 15 parts of calcium carbonate, 1.2 parts of anti-aging agent KY-405L and 210 parts of 120# gasoline are the raw materials for preparation; among them, every 4.5 parts of vulcanization accelerator is composed of 1.8 parts of accelerator M, 2.2 parts of accelerator DM and 0.5 parts of accelerator DS ; Every 4 parts of vulcanization activator is composed of 3.5 parts of active zinc oxide and 0.5 parts of stearic acid.

[0058] The preparation and use methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com