Polyethylene dacron coiled material-cementitious capillary crystalline waterproofing construction method

A technology of osmotic crystalline waterproofing and polyethylene polyester, which is applied in the direction of building insulation materials, building materials processing, building components, etc., can solve the problem of premature solidification and cracking temperature of waterproof coating layer, insufficient completion of cement hydration heat reaction, internal Insufficient number of microcrystals and other problems, to achieve the effect of low temperature resistance and waterproof, simple construction, and less constraints on the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

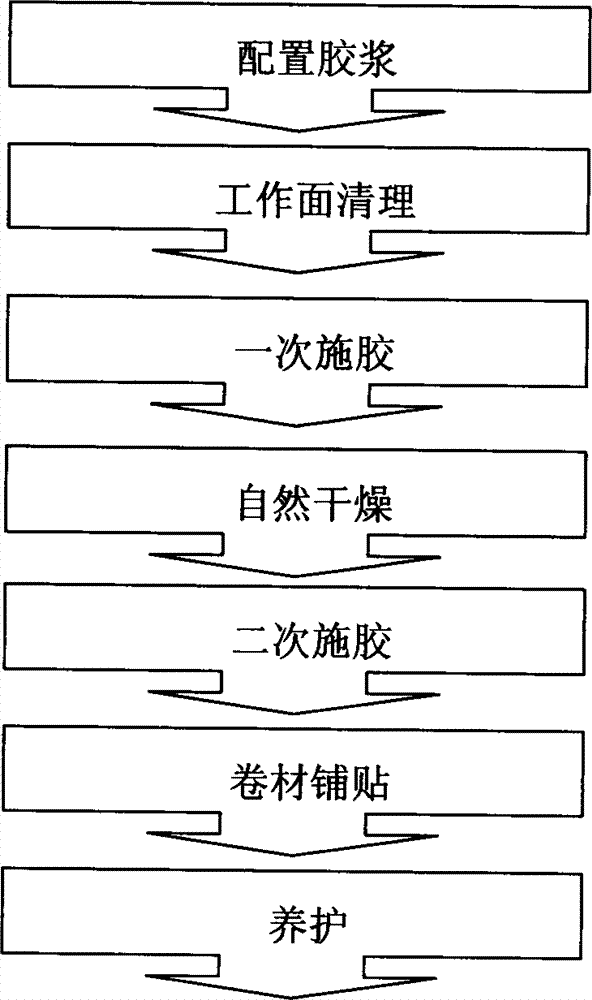

Image

Examples

Embodiment 1

[0017] The materials involved in this example include: polymer rubber powder, ordinary Portland 42.5 cement, cement-based permeable crystalline waterproof coating, polyethylene polyester waterproof membrane, and -10°C early-strength antifreeze.

[0018] The construction method is:

[0019] 1), configure mortar; by weight, prepare materials with polymer rubber powder: cement: cement-based permeable crystalline powder mixture: -10°C early-strength antifreeze: water=1: 200: 100: 0.5: 120, And mix and stir homogeneously to become glue for use.

[0020] 2) Cleaning of the working surface; remove the sundries and dirt on the cement-based surface to be waterproofed, find cracks, and repair the cracks exceeding 2mm with glue.

[0021] 3), one-time sizing; evenly spray or scrape the glue on the working surface; for the first time, use 100m 2 / 15kg as the benchmark, spray it evenly on the waterproof base layer with spraying equipment, so as not to flow.

[0022] 4) Natural drying; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com