Vulcanization bonding process by template method for conveying belt

A template method and bonding technology, used in belts, other household appliances, household appliances and other directions, can solve the problems of high vulcanization temperature, complex process, long bonding time, etc., to achieve a simple bonding process, improve work efficiency, save money The effect of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

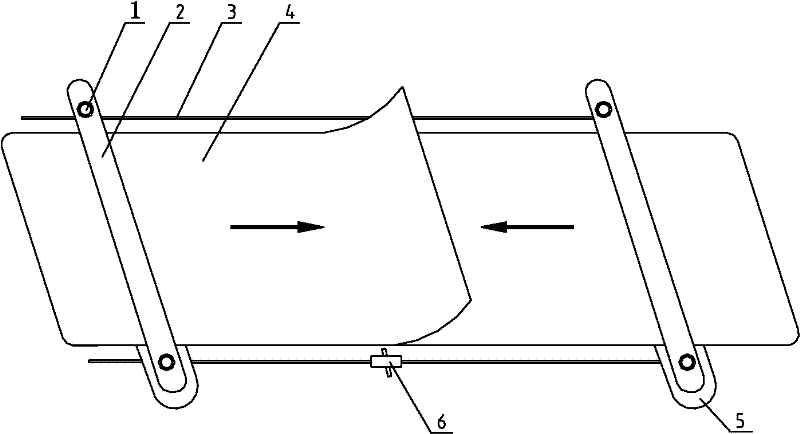

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

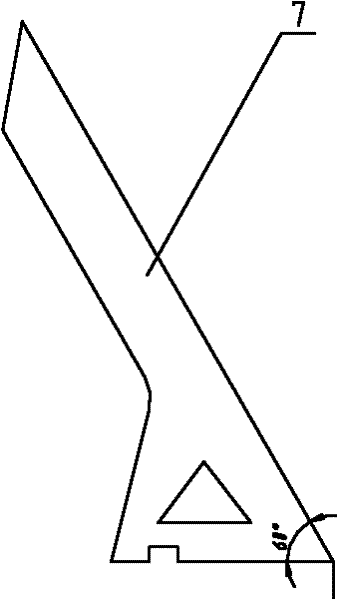

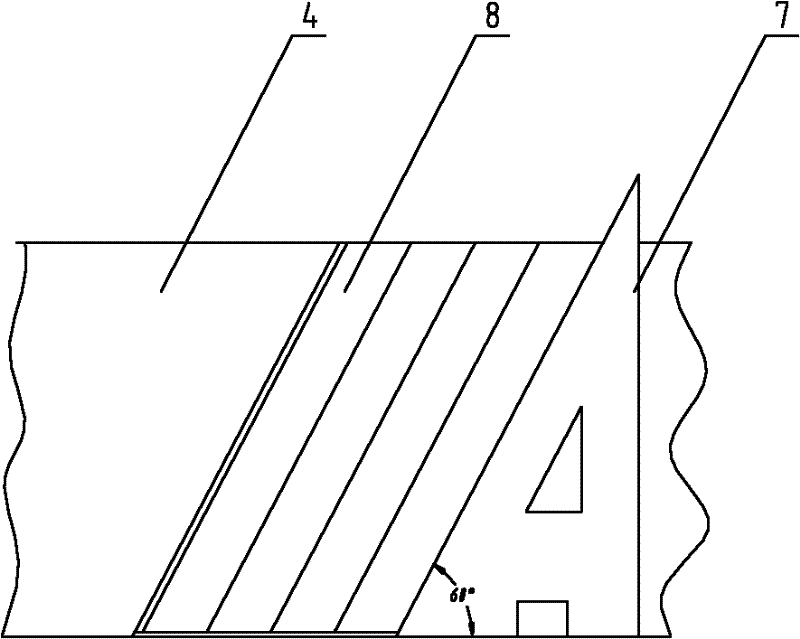

[0037] The design idea of the vulcanization bonding process in the present invention is: vulcanization bonding is to cut the cloth layer and the rubber layer at the joint of the tape into symmetrical differential steps according to a certain form and angle, apply glue to make it adhere, and then Under pressure and temperature conditions, heat for a certain period of time for vulcanization reaction, so that raw rubber becomes vulcanized rubber, so that the joint can obtain the best adhesive strength.

[0038] The process is described in detail below.

[0039] A template method vulcanization bonding process for conveyor belts, the steps of vulcanization bonding are:

[0040] (1) Turn the bonding int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com