Preparation method of wear-resistant butyronitrile gloves and wrinkling liquid used therefor

A wear-resistant nitrile and glove technology, applied in gloves, applications, clothing, etc., can solve the problems of wrinkle appearance consistency, insufficient wear resistance, long wrinkle operation time, and poor wrinkle effect, etc., to achieve shortened wrinkle Wrinkle processing time, beneficial to wrinkle reunion, and the effect of improving the wear resistance of gloves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

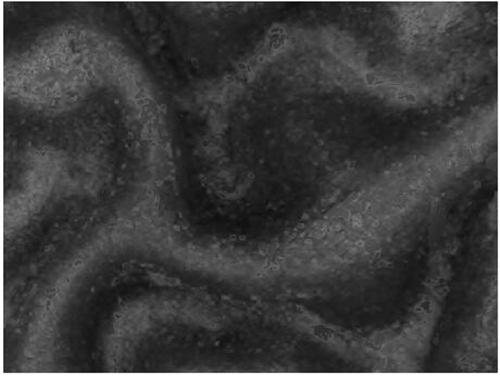

Image

Examples

Embodiment 1

[0040]A preparation method of wear-resistant nitrile gloves, comprising the steps of preparing nitrile wrinkling glue, preparing wrinkling solution, dipping nitrile wrinkling glue (dipping), dipping into wrinkling solution, and drying and vulcanizing, as follows:

[0041] S1. Preparation of nitrile creping mortar

[0042] Nitrile latex 830 is 100 parts by weight in terms of dry rubber mass content, that is, nitrile latex 830 is 227.3 parts by weight;

[0043] 1.0 parts by weight of 5wt% acrylonitrile fiber filament dispersion;

[0044] Ammonia 0.05 parts by weight;

[0045] 0.1 parts by weight of 50wt% ZnO dispersion;

[0046] 0.2 parts by weight of 50wt% sulfur dispersion;

[0047] 0.2 parts by weight of 50wt% accelerator ZDC dispersion;

[0048] 0.2 parts by weight of 40wt% accelerator TT dispersion;

[0049] 0.8 parts by weight of 50wt% antioxidant 264 dispersion;

[0050] 0.1 parts by weight of 30wt% diffusing agent NF dispersion;

[0051] 30wt% Pingpingjia dispersi...

Embodiment 2

[0069] A method for preparing wear-resistant nitrile gloves, comprising the steps of preparing nitrile wrinkling glue, preparing wrinkling solution, dipping nitrile wrinkling glue, dipping wrinkling solution, drying and vulcanizing, specifically as follows:

[0070] S1. Preparation of nitrile creping mortar

[0071] Nitrile latex 830 is 100 parts by weight in terms of dry rubber mass content;

[0072] 2.0 parts by weight of 5wt% acrylonitrile fiber silk dispersion;

[0073] Ammonia 0.06 parts by weight;

[0074] 0.3 parts by weight of 50wt% ZnO dispersion;

[0075] 0.6 parts by weight of 50wt% sulfur dispersion;

[0076] 0.3 parts by weight of 50wt% accelerator ZDC dispersion;

[0077] 0.3 parts by weight of 40wt% accelerator TT dispersion;

[0078] 50wt% antioxidant 264 dispersion 1.0 parts by weight;

[0079] 0.2 parts by weight of 30wt% diffusing agent NF dispersion;

[0080] 30wt% Pingpingjia dispersion 0.02 parts by weight;

[0081] 12 parts by weight of 30% heavy...

Embodiment 3

[0098] A preparation method of wear-resistant nitrile gloves, comprising the steps of preparing nitrile wrinkling glue, preparing wrinkling liquid, dipping nitrile wrinkling glue, dipping wrinkling liquid, drying and vulcanizing, specifically as follows:

[0099] S1. Preparation of nitrile creping mortar

[0100] Nitrile latex 830 is 100 parts by weight in terms of dry rubber mass content;

[0101] 3.0 parts by weight of 5wt% acrylonitrile fiber filament dispersion;

[0102] Ammonia 0.08 parts by weight;

[0103] 0.5 parts by weight of 50wt% ZnO dispersion;

[0104] 1 part by weight of 50wt% sulfur dispersion;

[0105] 0.5 parts by weight of 50wt% accelerator ZDC dispersion;

[0106] 0.4 parts by weight of 40wt% accelerator TT dispersion;

[0107] 1.2 parts by weight of 50wt% antioxidant 264 dispersion;

[0108] 0.3 parts by weight of 30wt% diffusing agent NF dispersion;

[0109] 30wt% Pingpingjia dispersion 0.03 parts by weight;

[0110] 15 parts by weight of 30% heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com