Rubber cement soil and preparation method thereof

A technology of rubber cement and cement, which is applied in the field of rubber cement soil and rubber cement soil preparation, can solve the problems of human living environment pollution, etc., and achieve the effects of reducing environmental pollution, improving recycling rate, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

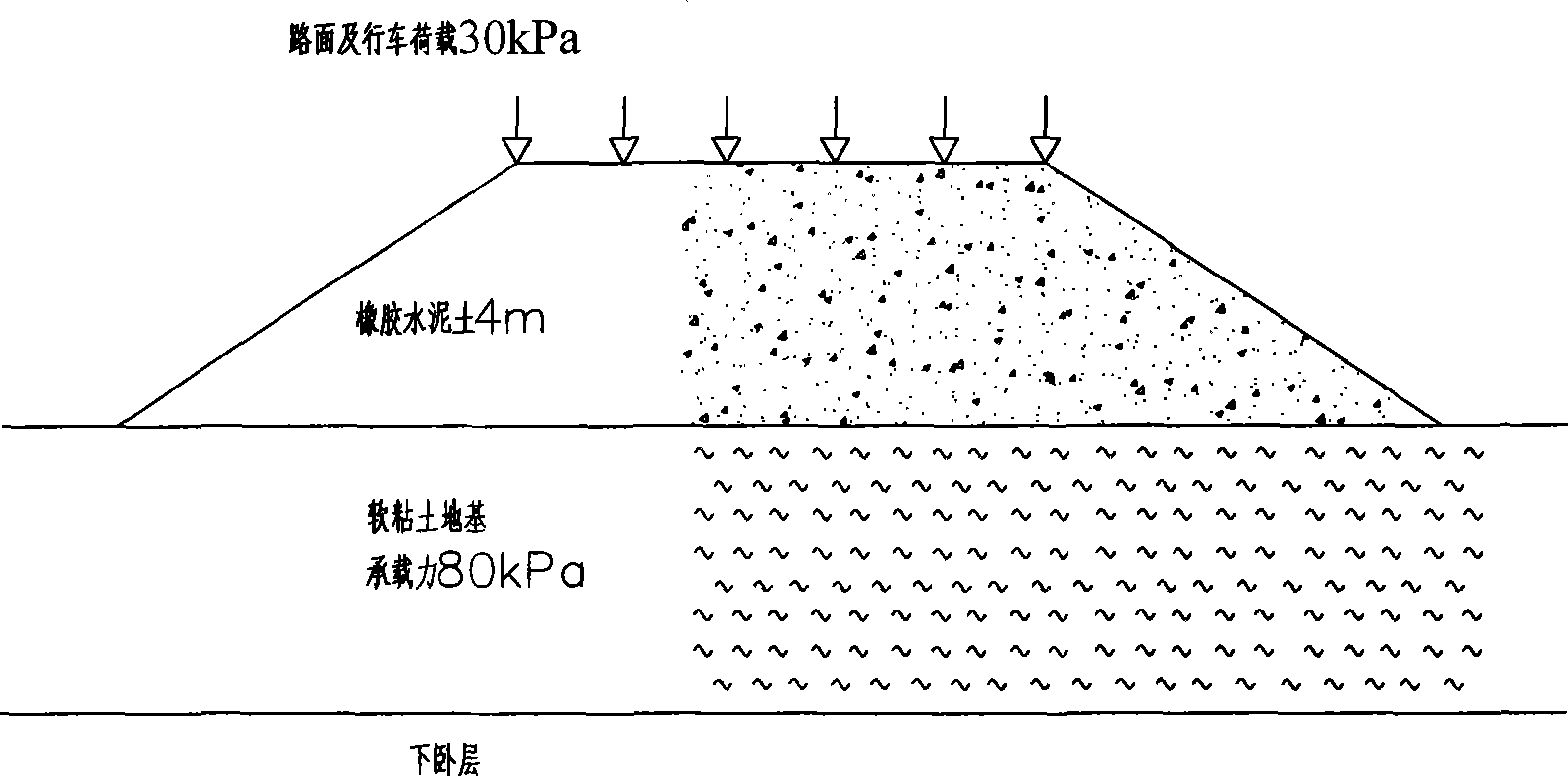

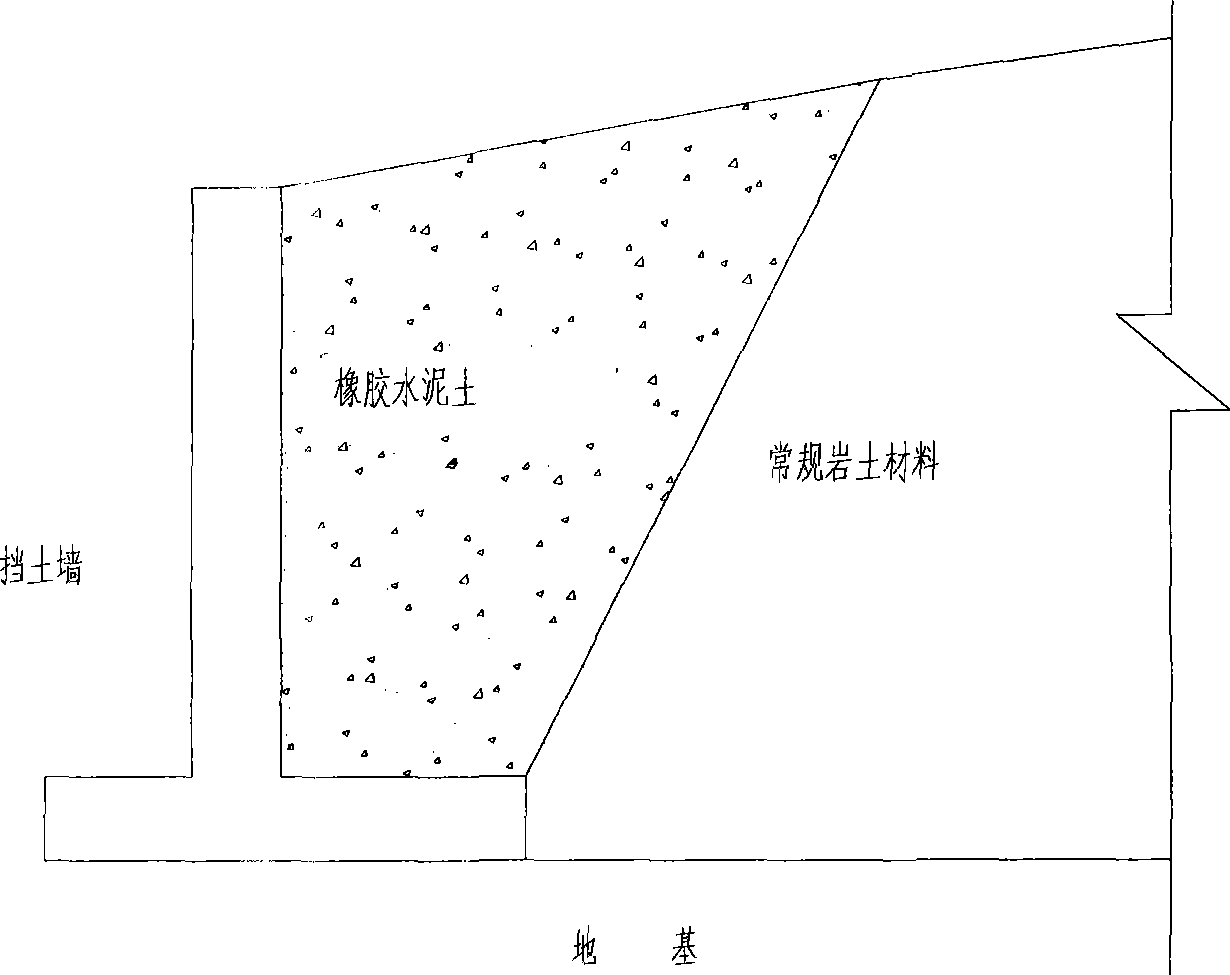

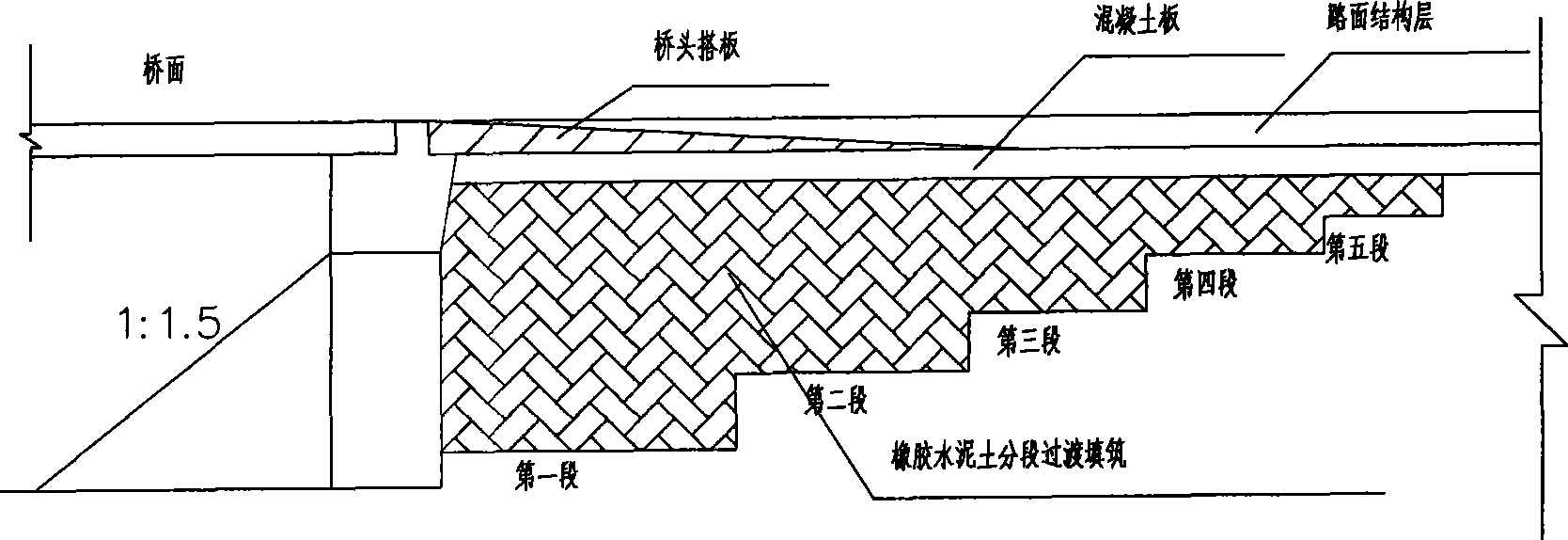

[0028] Rubber cement soil of the present invention, it is made up of waste rubber particle, cement, water, sand, and described waste rubber particle: cement: water: the weight percent of sand is 1-2.5:1:0.3-0.5:0-1, waste rubber The particle size of the particles is 0.1-10mm, and the waste rubber particles include waste rubber particles processed from waste tires, pipes, belts, industrial rubber products, rubber shoes and rubber factory waste. When the weight percentage of waste rubber particles: cement: water: sand is 100:100:50:50, it has a more suitable unconfined compressive strength, and its density is lower than that of cohesive soil, which is a good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com