Natural/butadiene rubber formula for hovership finger and manufacturing method thereof

A kind of cis-butadiene rubber and natural rubber technology, applied in the rubber field, can solve the problems of finger failure, accelerated tearing of rubber layer and skeleton material, finger rubber layer wear, etc. abrasive effect

Active Publication Date: 2013-03-13

TIANJIN RUBBER IND RES INST

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hovercraft is violently beaten and repeatedly flexed by wind, waves and airflow, causing the rubber layer of the finger to wear, accelerating the tearing and delamination between the rubber layer and the skeleton material, resulting in rapid failure of the finger

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

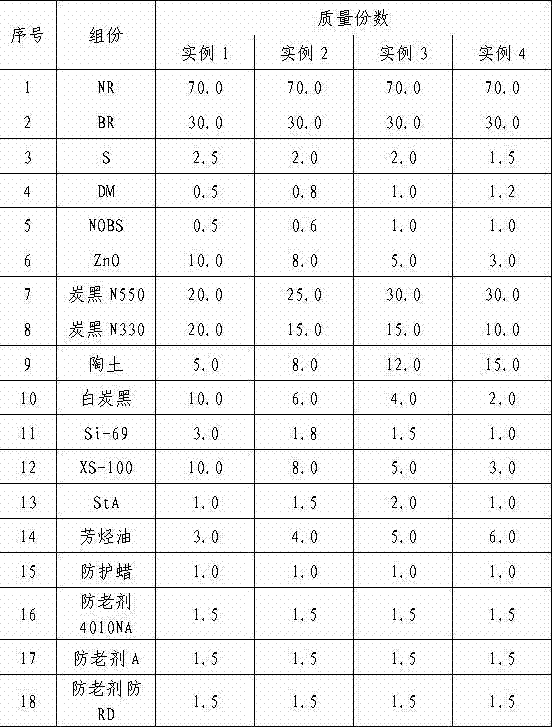

[0055] A hovercraft finger with natural / butadiene rubber implemented in the following formulation:

[0056] In parts by weight:

[0057]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a natural / butadiene rubber formula for a hovership finger and a manufacturing method thereof. The manufacturing method comprises the following step of: carrying out banburying, opening, batching-off and vulcanizing on NR (Natural Rubber), BR (Butadiene Rubber), S, DM, NOBS (N-(Oxidiethylene)-2-benzothiazolyl sulfonamide), ZnO, carbon black N550, carbon black N330, argil, white carbon black, Si-69, a rubber cement XS-100, StA, aromatic oil, protection wax, anti-aging agent 4010NA, anti-aging agent A and RD. The BR is used in the NR, the compound cement XS-100 with good dispersing property is adopted and is high in feeding; and the manufacturing method is simple and easy to operate; and a less quantity of BR is adopted in the NR, so that the abrasive resistance is improved; and the white carbon black and si-69 are matched for use, so that the bonding strength of rubber and a framework material can be greatly improved.

Description

technical field [0001] The invention belongs to the technical field of rubber, in particular to a formula of natural / butadiene rubber for hovercraft fingers and a production method thereof. Background technique [0002] Hovercraft use harsh conditions, and its replaceable parts—fingers are always one of the main factors affecting the service life of the hovercraft. The hovercraft is violently beaten and repeatedly flexed by wind waves and air currents, which causes the rubber layer of the finger to wear, accelerates the tearing and delamination between the rubber layer and the skeleton material, and leads to rapid failure of the finger. In short, the abrasion resistance of the rubber of the hovercraft fingers, and the low bond strength properties of the rubber and the frame material are the reasons for this phenomenon. Contents of the invention [0003] Aiming at the deficiencies in the existing rubber technology, the purpose of the present invention is to solve the wear...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L7/00C08L9/00C08K13/02C08K3/22C08K3/04C08K3/34C08K3/36C08K5/09

Inventor 原晓城马义明张景亮姬燕飞魏智李学东郑玥

Owner TIANJIN RUBBER IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com