Online resourceful treatment method for chemical copper plating waste liquid

A technology of chemical copper plating and treatment method, applied in chemical instruments and methods, liquid chemical plating, metallurgical wastewater treatment, etc., can solve the problems of low copper recovery rate, low copper ion removal rate, and substandard waste liquid treatment indicators. , to reduce the burden and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

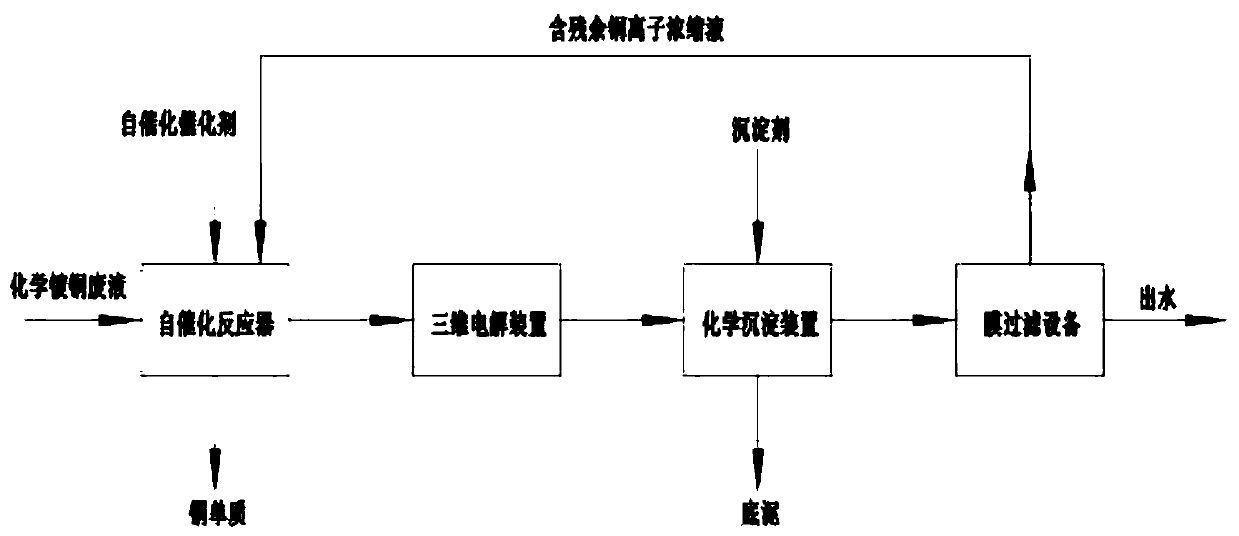

[0027] like figure 1 Shown, a kind of online resource processing method of electroless copper plating waste liquid, comprises the following steps:

[0028] (1) Autocatalytic reaction: introduce the filtered electroless copper plating waste liquid into the autocatalytic reactor, adjust the pH to 13.5, control the temperature at 65°C, and add copper-based catalysts according to 6g / L, copper-based catalysts According to weight percentage, it includes: 26% of nano-copper, 0.5% of cerium oxide, and the balance of nano-cuprous oxide. Under the condition of electromagnetic oscillation, the self-catalytic reduction reaction is carried out by aeration and stirring, the copper ions in the electroless copper plating waste liquid are reduced to copper simple substances, the copper simple substances are recycled and filtered, and the circulating water is returned to the self-reaction catalyst until the electroless copper plating After the concentration of copper ions in the waste liquid i...

Embodiment 2

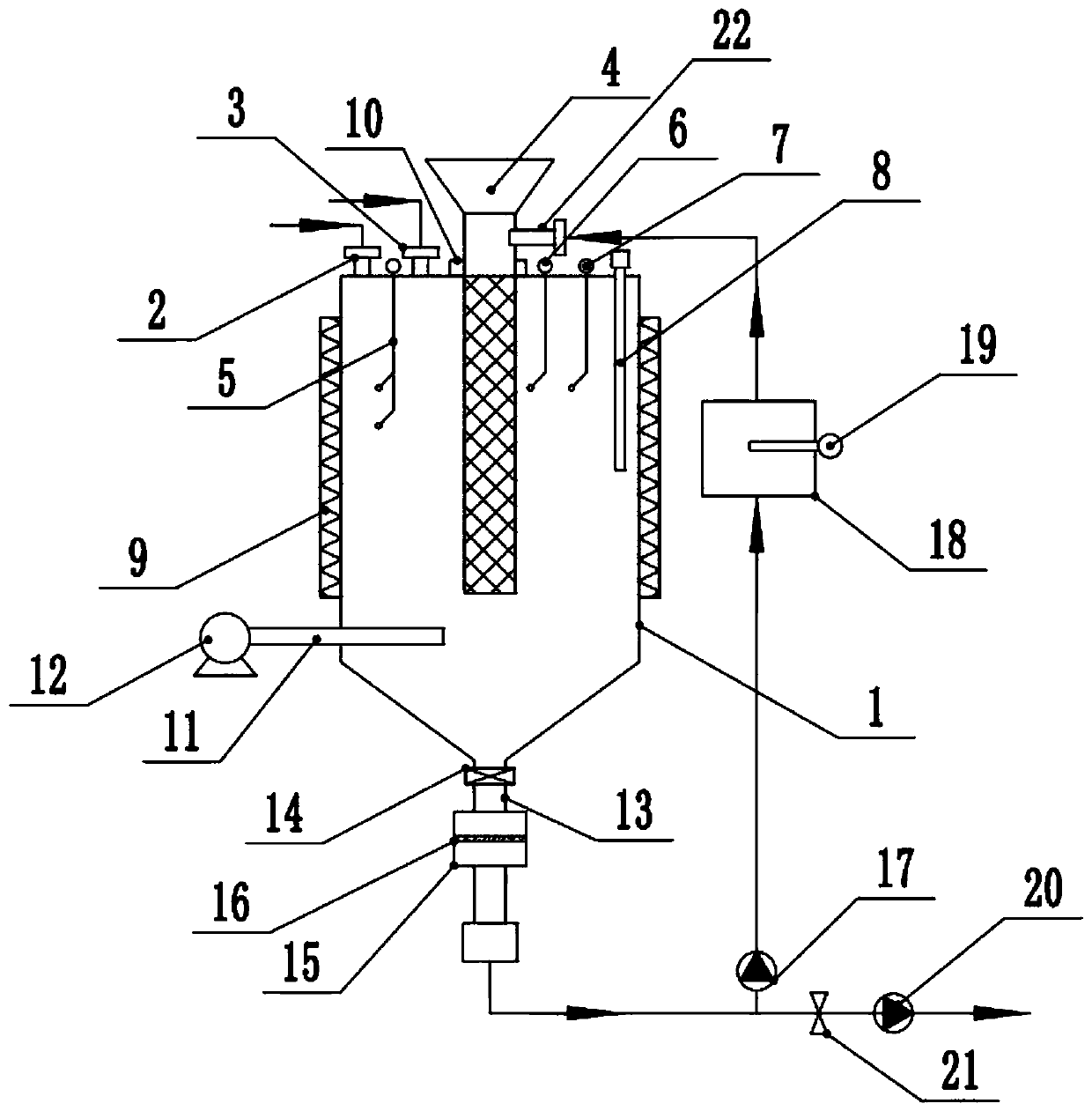

[0034] This embodiment is basically the same as Embodiment 1, the difference is: as figure 2 As shown, in step 1, the self-catalytic reactor includes a reaction tank 1, a catalyst delivery frame 4, an induction coil 9, and a copper element separation box 15. The reaction tank 1 is made of a ceramic insulating material, and the reaction tank 1 is provided with a movable insertion catalyst delivery frame. Jack 10 of 4, and electroless copper plating waste liquid inlet 2 and lye inlet 3, the catalyst throwing frame 4 is provided with backflow port 22, and reaction tank 1 is also provided with temperature probe 5, pH probe 6, copper ion detection probe 7 and a heating rod 8, the bottom of the reaction tank 1 is provided with an aeration tube 11 for aeration and stirring, the aeration tube 11 is connected with an external air pump 12, and the induction coil 9 is wound on the outer wall of the reaction tank 1, and the induction coil 9 The oscillating circuit is electrically connect...

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 2, and the difference points out that, as figure 2 As shown, a backflow box 18 is provided on the pipeline connected to the backflow port 22 , and an ultrasonic vibrating rod 19 is provided in the backflow box 18 for ultrasonically activating the backflow water accumulated in the backflow box 18 . The circulating wastewater activated by ultrasound is more likely to react with copper-based catalysts to improve the reduction efficiency of copper ions.

[0039] Water quality testing was carried out on the purified wastewater, the detected amount of copper in the effluent was 0.07mg / L, the effective removal rate of copper ions was 97.8%, the recovery rate of simple copper was 90%, the detected amount of ammonia nitrogen was 2mg / L, and the detected amount of COD was 26mg / L , the index after treatment of electroless copper plating waste liquid can reach the standard in Table 2 of "Electroplating Pollutant Discharge Standard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com