A continuous refining method and device for high-purity ε-caprolactone

A caprolactone, high-purity technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, organic chemistry, etc., can solve the problems of not meeting the requirements of polycaprolactone application, large difference in boiling point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

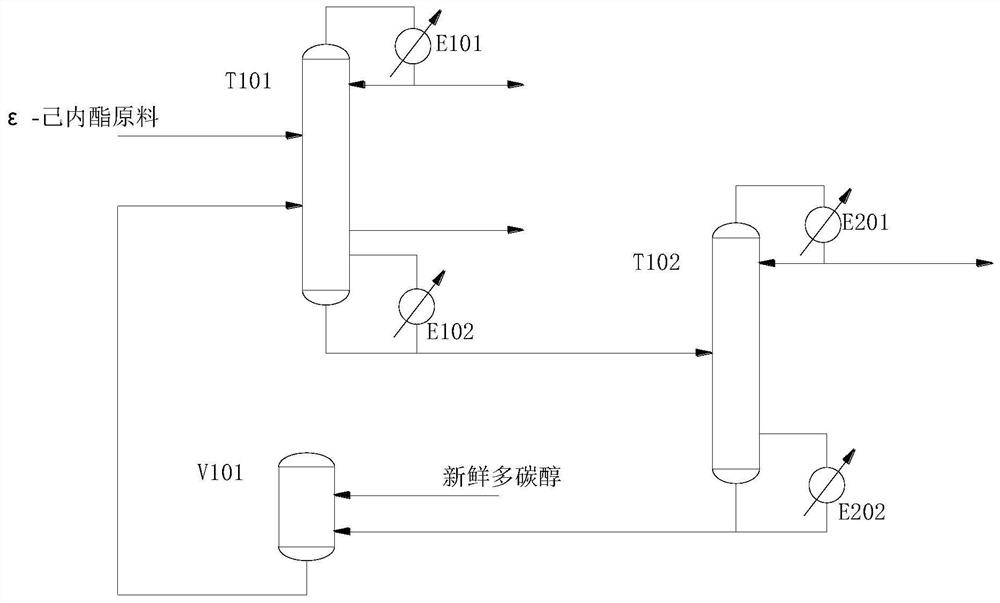

[0036] A continuous refining method for high-purity ε-caprolactone comprises a refining system composed of a reactive distillation column and an azeotropic distillation column. The ε-caprolactone from the ε-caprolactone raw material tank is added from the middle of the reactive distillation tower T101, and the polycarbonate alcohol from the polycarbonate alcohol circulation tank V101 is added from the lower part of the tower. After the countercurrent contact between the polycarbonate alcohol and ε-caprolactone A self-catalyzed esterification reaction occurs, unreacted polycarbonate alcohols, low-boiling-point esters produced by the reaction and water in the raw materials are evaporated from the top of the tower and then enter the top condenser E101 of T101. The raw material of boiling distillation column T102, the bottom side line of T101 extracts ε-caprolactone with a purity ≥ 99.95%, and the bottom of the tower extracts high-boiling point esters generated by the reaction and ...

Embodiment 2

[0043] A continuous refining method for high-purity ε-caprolactone comprises a refining system composed of a reactive distillation column and an azeotropic distillation column. The ε-caprolactone from the ε-caprolactone raw material tank is added from the middle of the reactive distillation tower T101, and the polycarbonate alcohol from the polycarbonate alcohol circulation tank V101 is added from the lower part of the tower. After the countercurrent contact between the polycarbonate alcohol and ε-caprolactone A self-catalyzed esterification reaction occurs, unreacted polycarbonate alcohols, low-boiling-point esters produced by the reaction and water in the raw materials are evaporated from the top of the tower and then enter the top condenser E101 of T101. The raw material of boiling distillation column T102, the bottom side line of T101 extracts ε-caprolactone with a purity ≥ 99.95%, and the bottom of the tower extracts high-boiling point esters generated by the reaction and ...

Embodiment 3

[0050] A continuous refining method for high-purity ε-caprolactone comprises a refining system composed of a reactive distillation column and an azeotropic distillation column. The ε-caprolactone from the ε-caprolactone raw material tank is added from the middle of the reactive distillation tower T101, and the polycarbonate alcohol from the polycarbonate alcohol circulation tank V101 is added from the lower part of the tower. After the countercurrent contact between the polycarbonate alcohol and ε-caprolactone A self-catalyzed esterification reaction occurs, unreacted polycarbonate alcohols, low-boiling-point esters produced by the reaction and water in the raw materials are evaporated from the top of the tower and then enter the top condenser E101 of T101. The raw material of boiling distillation column T102, the bottom side line of T101 extracts ε-caprolactone with a purity ≥ 99.95%, and the bottom of the tower extracts high-boiling point esters generated by the reaction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com