Lithium sulfide/carbon composite material with multilevel structure as well as preparation method and application of lithium sulfide/carbon composite material

A carbon composite material and lithium sulfide technology, which is applied in the field of material science, can solve the problems of carbon/lithium sulfide composite material with general, unsatisfactory structural stability, and does not effectively solve the problems of lithium sulfide active material dispersion, etc., and achieves excellent cycle specific capacity and The effect of capacity retention, alleviation of volume expansion and contraction, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

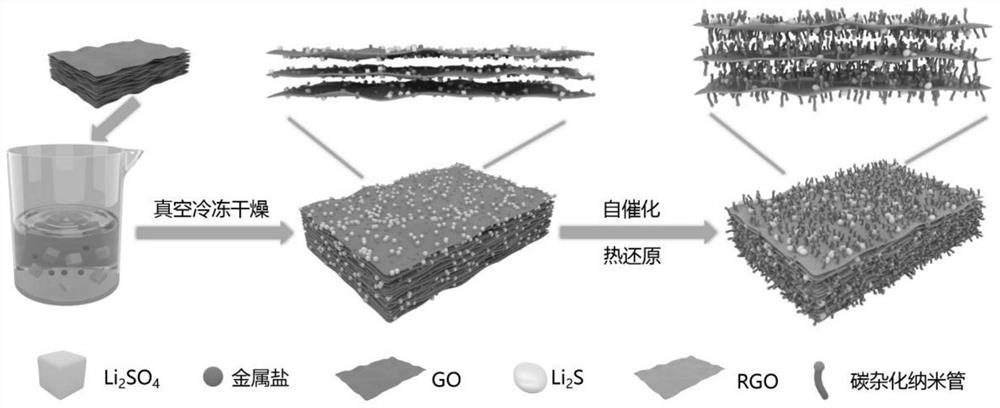

[0058] The present embodiment provides a kind of preparation method of multi-level structure lithium sulfide / carbon composite material, such as figure 1 Shown, described preparation method comprises:

[0059] (1) 2.5g of Co(NO 3 ) 2 ·6H 2 O is dissolved in 50mL deionized water to obtain a cobalt salt solution with a concentration of 5wt%, adding 0.1g of lithium sulfate to dissolve in the cobalt salt solution, and then adding 50mL of a graphene oxide solution with a concentration of 10mg / mL to obtain a mixed solution;

[0060] (2) Stir the mixed solution obtained in step (1) for 12h at a speed of 500rpm / min, then perform ultrasonic dispersion for 30min, then centrifuge at a speed of 8000rpm / min for 5min to obtain a precipitate, and then place the precipitate Pretreatment in liquid nitrogen for 10 minutes, vacuum freeze-drying for 12 hours to obtain the precursor material;

[0061] (3) Place the melamine powder and the precursor material obtained in step (2) on both ends of ...

Embodiment 2

[0063] The present embodiment provides a kind of preparation method of multi-level structure lithium sulfide / carbon composite material, such as figure 1 Shown, described preparation method comprises:

[0064] (1) 2.5g of Fe(NO 3 ) 2 9H 2 O is dissolved in 50mL deionized water to obtain a concentration of 5wt% iron salt solution, adding 0.1g lithium sulfate is dissolved in the iron salt solution, and then adding 50mL concentration of graphene oxide solution of 10mg / mL to obtain a mixed solution;

[0065] (2) Stir the mixed solution obtained in step (1) for 12h at a speed of 500rpm / min, then perform ultrasonic dispersion for 30min, then centrifuge at a speed of 8000rpm / min for 5min to obtain a precipitate, and then place the precipitate Pretreatment in liquid nitrogen for 10 minutes, vacuum freeze-drying for 12 hours to obtain the precursor material;

[0066] (3) Place the urea powder and the precursor material obtained in step (2) at both ends of the porcelain boat at a mas...

Embodiment 3

[0068] The present embodiment provides a kind of preparation method of multi-level structure lithium sulfide / carbon composite material, such as figure 1 Shown, described preparation method comprises:

[0069] (1) Add 2.5g of Ni(NO 3 ) 2 ·6H 2 O is dissolved in 50mL deionized water to obtain a concentration of 5wt% nickel salt solution, add 0.1g lithium sulfate to dissolve in the nickel salt solution, then add 50mL concentration of graphene oxide solution of 10mg / mL to obtain a mixed solution;

[0070] (2) Stir the mixed solution obtained in step (1) for 12h at a speed of 500rpm / min, then perform ultrasonic dispersion for 30min, then centrifuge at a speed of 8000rpm / min for 5min to obtain a precipitate, and then place the precipitate Pretreatment in liquid nitrogen for 10 minutes, vacuum freeze-drying for 12 hours to obtain the precursor material;

[0071] (3) Place the melamine powder and the precursor material obtained in step (2) at both ends of the porcelain boat at a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com