Dissolving pulp prehydrolysis solution autocatalysis furfuraldehyde preparation method and recycling method for acetic acid in prehydrolysis solution waste water and furfuraldehyde waste water

A technology of pre-hydrolyzed solution and dissolving pulp, which is applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of organic compounds, etc. It can solve problems such as poor flexibility of production operations, deposition of dissolved organic matter, long natural degradation time of lignin, etc. , to achieve the effect of reducing coking and humus formation, avoiding resin reaction, and facilitating subsequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

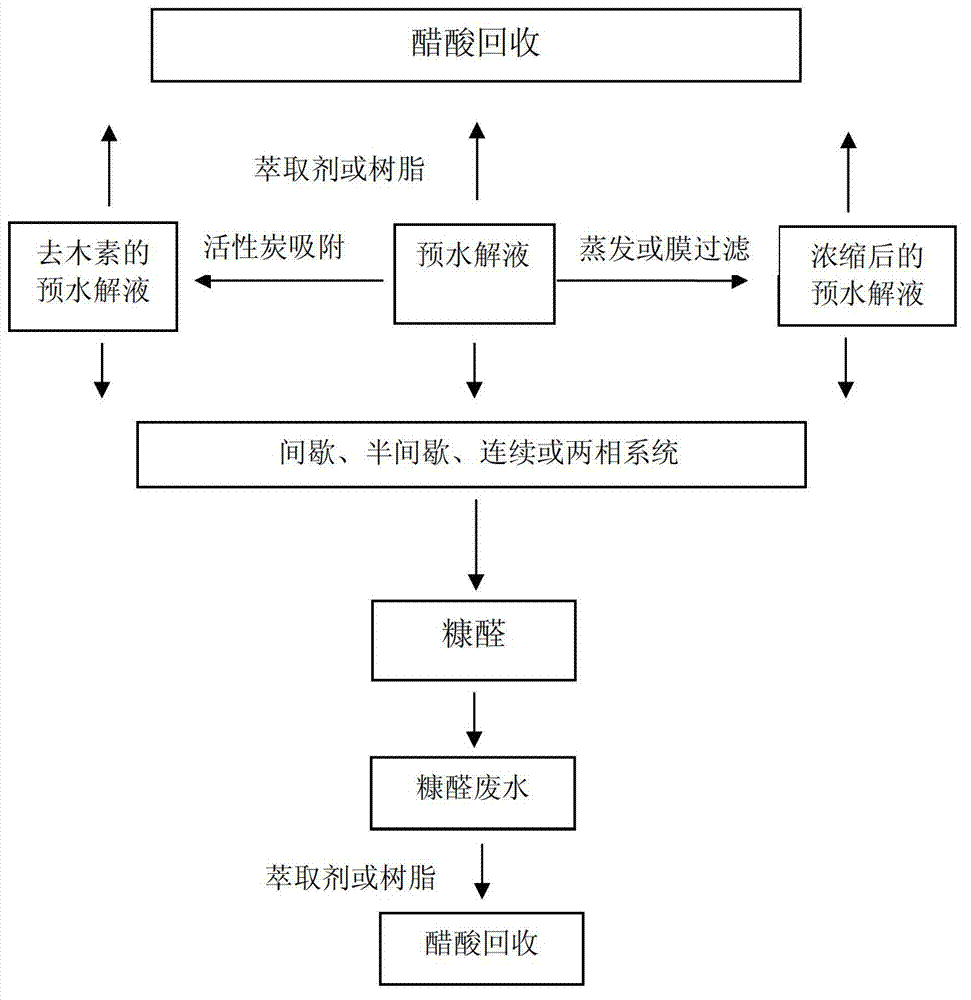

[0077] See figure 1 , One of the methods for preparing furfural by autocatalytic reaction of dissolving pulp prehydrolyzate A, 300mL of dissolving pulp prehydrolyzate A is placed in a high-pressure reactor, without adding any other sulfuric acid, hydrochloric acid or acetic acid catalysts for intermittent autocatalytic reaction, the reaction temperature is 150 ℃-220 ℃, the reaction temperature of this example is designed to be 170 ℃, the pressure is 0.23MPa-2.32MPa, the pressure of this example is designed to be 0.54MPa-0.57MPa, and the retention time is 20min-160min. The retention time of this example is designed to be 100min. During the process, the polysaccharide is hydrolyzed into pentose, and the pentose is dehydrated and cyclized. After the reaction is completed, the content of total sugar and five-carbon sugar in the receiving solution is measured by ion chromatography, the conversion rate of total sugar and five-carbon sugar is calculated, and the acetic acid is determ...

Embodiment 2

[0082] See figure 1 , The second method of preparing furfural by autocatalytic reaction of dissolving pulp prehydrolyzate A is to put 300mL of hardwood kraft dissolving pulp prehydrolyzate A in a high-pressure reactor for semi-batch autocatalytic reaction, stirring in an automatic mixer at about 80 r / min Start heating at a high speed, and when the temperature of the reaction system reaches 180°C, open the gas phase discharge valve to discharge aldehyde vapor, condense and collect the aldehyde-water mixture, close the gas phase discharge valve after the reaction, turn off the power to cool down, and use ion chromatography to measure the total sugar and Five-carbon sugar content, calculate total sugar, five-carbon sugar conversion rate, adopt nuclear magnetic resonance to measure the concentration of acetic acid and furfural, and the measurement results are shown in Table 2:

[0083] Table 2

[0084] Concentration of furfural in aldehyde water (g / L) Furfural sele...

Embodiment 3

[0087] See figure 1 , Dissolving pulp prehydrolyzate A self-catalyzed reaction to prepare furfural method three, 300mL

[0088] The prehydrolyzate A of hardwood kraft dissolving pulp is placed in a high-pressure reactor, and an equal volume of methyl isobutyl ketone is added as an extractant in a two-phase system. The reaction temperature is 170°C, the pressure is 0.54-0.57MPa, and the retention time 100min to carry out batch reaction, after the reaction is completed, separate the aqueous phase and the organic phase, and measure the two phases respectively, adopt ion chromatography to measure the content of total sugar and five-carbon sugar in the receiving liquid, calculate the conversion rate of total sugar and five-carbon sugar, and use The concentration of acetic acid and furfural was measured by nuclear magnetic resonance, and the measurement results are shown in Table 3:

[0089] table 3

[0090] Concentration of furfural in liquid phase after reaction (g / L)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com