Metal-based autocatalytic reactor based on 3D printing as well as preparation method and application of metal-based autocatalytic reactor

A 3D printing and self-catalysis technology, applied in the field of reactors, can solve the problems of low mechanical strength, slow molding speed, and reduction of catalysts, and achieve the effects of increasing effective catalytic area, optimizing catalytic function, and facilitating new designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In this application, the applicant provides a metal-based autocatalytic reactor using 3D printing technology and its preparation method. The preparation method includes the following steps:

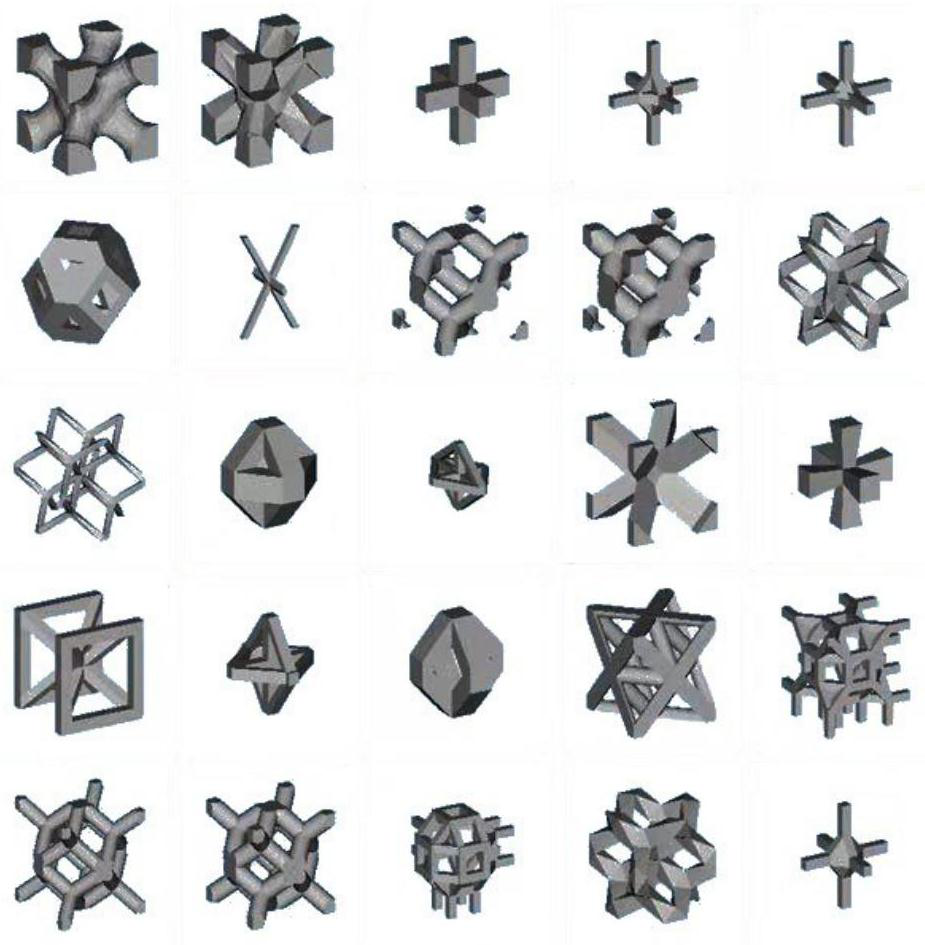

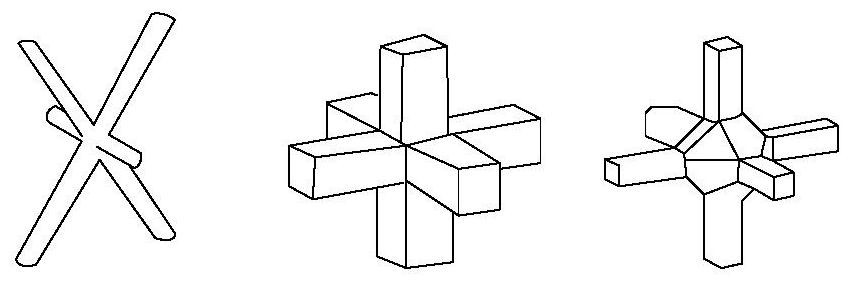

[0053] 1) Use 3D software to design the structure of the autocatalytic reactor, and the skeleton of the structure is filled with repeating structural units;

[0054] 2) Use metal powder as the printing material, set the printing parameters, and perform 3D printing in a protective atmosphere;

[0055] 3) Annealing to separate the printed part from the substrate;

[0056] 4) Roasting, reduction treatment.

[0057]In a specific embodiment, the three-dimensional software is selected from one of AutoCAD, 3DMAX, SolidWorks and Materialize Magics. For example, choose Materialize Magics. More specifically, use Materialize Magics to create the structural module, and then select the structure, that is, select a certain repeating structural unit to fill the skeleton structure of the autoca...

Embodiment 1

[0088] The preparation method of iron-based autocatalytic reactor in the present embodiment comprises the steps:

[0089] Step (1): Use the modeling software Materialize Magics to design a 3D model of a cylindrical reactor with a pore structure that has been optimized by the fluid simulation software (CFD). The diameter D of the reactor is 10mm, the height H is 50mm, and the bottom / top holes The diameter d of the reactor is 1.5mm, and the size of the internal filling repeating structural unit is 1.0mm in the XYZ direction, and the structural model of the 3D autocatalytic reactor is converted into stl. format.

[0090] Step (2): Prepare suitable metal powder as the printing material. The metal powder is made of iron. The particle size of the above metal powder is required to be 10-60 μm, the sphericity of the particles is not less than 95%, and the metal particles are guaranteed to be dry enough. Set the printing process parameters as follows: the laser power is 300W, ensuring ...

Embodiment 2

[0095] The preparation method of nickel-based autocatalytic reactor in the present embodiment comprises the steps:

[0096] Step (1): Use the modeling software Materialize Magics to design a 3D model of a cylindrical reactor with a pore structure that has been optimized by the fluid simulation software (CFD). The diameter D of the reactor is 10mm, the height H is 50mm, and the bottom / top holes The diameter d of is 1.5mm, the size of the repeating structural units filled inside is 1.0mm in the XYZ direction, and the structural model of the 3D self-catalytic reactor is converted into stl. format.

[0097] Step (2): Prepare suitable metal powder as the printing material. The metal powder is made of nickel. The particle size of the above metal powder is required to be 10-60 μm, the sphericity of the particles is not less than 95%, and the metal particles are guaranteed to be sufficiently dry. Set the printing process parameters as follows: the laser power is 350W, ensuring that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com