A nickel nanofiber membrane for membrane catalysis and preparation method thereof

A nanofiber membrane and nanofiber technology, which is applied in chemical instruments and methods, fiber treatment, physical/chemical process catalysts, etc., can solve the problem of high activity and high-efficiency catalytic functions of supported nickel-based catalysts, as well as mass production and reduction Problems such as the number of NiB particles, the effective catalytic area, and the complex use process of supported catalysts have achieved the effect of easy to achieve large-scale preparation, improving catalytic efficiency and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

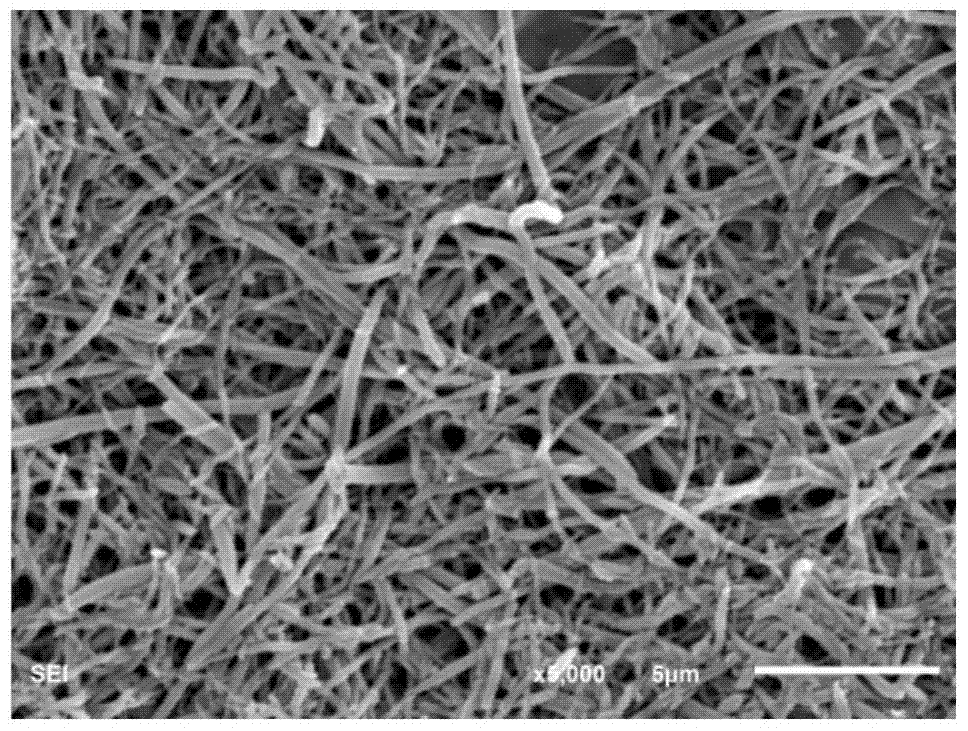

[0035] A preparation method of nickel nanofiber membrane for membrane catalysis, including the following steps:

[0036] 1) 0.2kg of thermoplastic polymer PVA-co-PE and 3.8kg of cellulose acetate butyrate are uniformly mixed, extruded and pelletized in a twin-screw extruder with a processing temperature of 170°C to prepare PVA -co-PE / cellulose acetate butyrate composite material.

[0037] 2) The PVA-co-PE / cellulose acetate butyrate composite material obtained in step 1) is drawn by a melt spinning machine and spun to obtain a composite fiber;

[0038] 3) The composite fiber is refluxed in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, and the composite fiber after the cellulose acetate butyrate is extracted is dried at room temperature to prepare PVA-co-PE nanofibers with an average diameter of 50 nm .

[0039] 4) Take 0.5g of PVA-co-PE nanofiber and disperse it in 500ml of ethanol to form a nanofiber dispersion, and then coat the nanofiber dispersion on the surf...

Embodiment 2

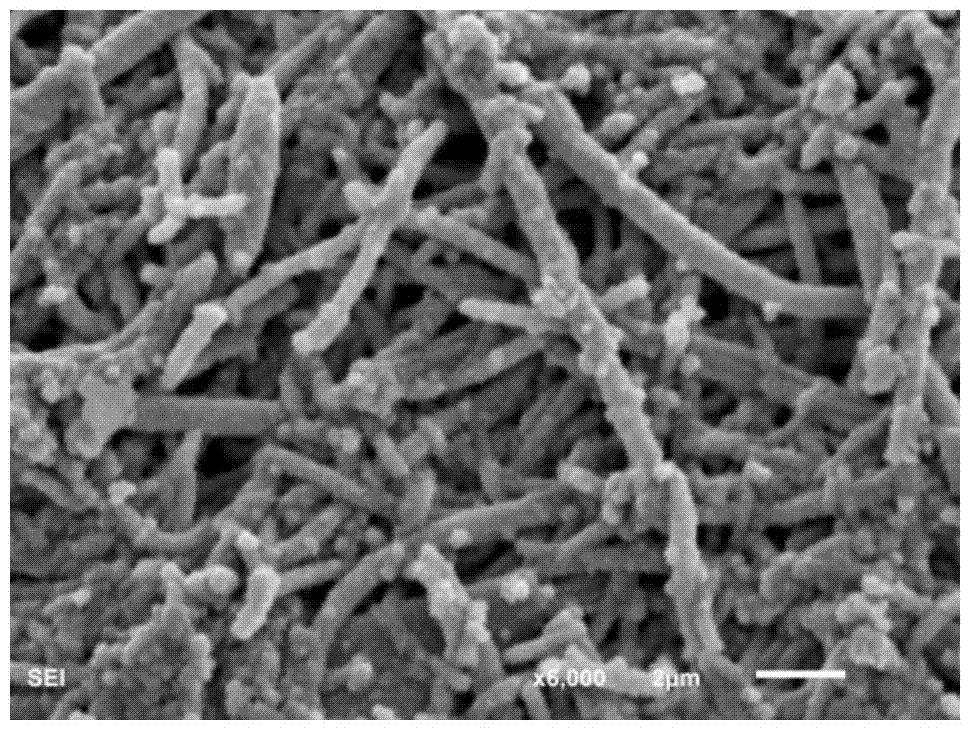

[0049] A preparation method of nickel nanofiber membrane for membrane catalysis, including the following steps:

[0050] 1) 0.5kg of thermoplastic polymer PVA-co-PE and 4kg of cellulose acetate butyrate are uniformly mixed, and extruded and pelletized in a twin-screw extruder with a processing temperature of 170°C to prepare PVA- co-PE / cellulose acetate butyrate composite material.

[0051] 2) The PVA-co-PE / cellulose acetate butyrate composite material obtained in step 1) is drawn by a melt spinning machine and spun to obtain a composite fiber;

[0052] 3) The composite fiber was refluxed in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, and the composite fiber after extraction of cellulose acetate butyrate was dried at room temperature to prepare PVA-co-PE nanofibers with an average diameter of 100 nm .

[0053] 4) Disperse 0.7g of PVA-co-PE nanofibers in 700ml of ethanol to form a nanofiber dispersion, then coat the nanofiber dispersion on the surface of a smoo...

Embodiment 3

[0063] A preparation method of nickel nanofiber membrane for membrane catalysis, including the following steps:

[0064] 1) 1kg of thermoplastic polymer PVA-co-PE and 4kg of cellulose acetate butyrate are uniformly mixed, extruded and pelletized in a twin-screw extruder with a processing temperature of 170°C to prepare PVA-co -PE / cellulose acetate butyrate composite material.

[0065] 2) The PVA-co-PE / cellulose acetate butyrate composite material obtained in step 1) is drawn and spun by a melt spinning machine to obtain a composite fiber.

[0066] 3) The composite fiber was refluxed in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, and the composite fiber after extracting cellulose acetate butyrate was dried at room temperature to prepare PVA-co-PE nanofibers with an average diameter of 200 nm .

[0067] 4) Disperse 0.5g of PVA-co-PE nanofibers in 500ml of ethanol to form a nanofiber dispersion, and then coat the nanofiber dispersion on the surface of a smooth pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com