A kind of ferromolybdenum catalyst with core-shell structure and its preparation and application

A core-shell structure and catalyst technology, which is used in catalyst activation/preparation, oxidation to prepare carbonyl compounds, physical/chemical process catalysts, etc. problem, to achieve the effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

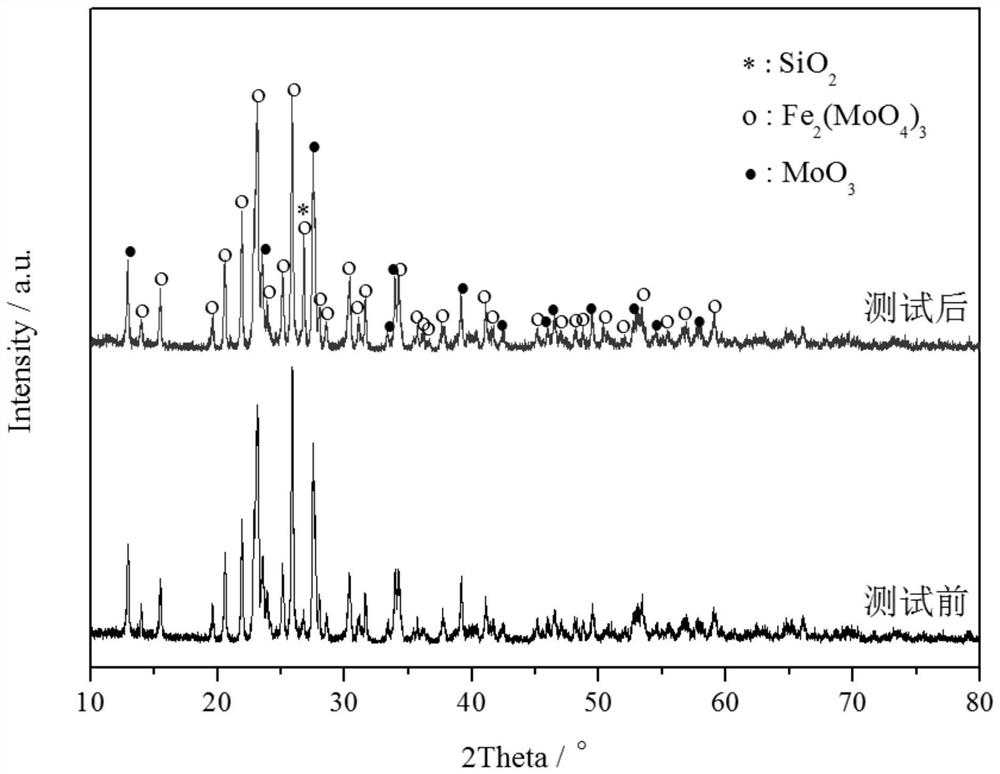

Image

Examples

preparation example Construction

[0022] A method for preparing a molybdenum-iron catalyst with a core-shell structure, comprising the following steps: preparing a ferric nitrate solution, weighing dried molybdenum trioxide, completing the process of impregnating a molybdenum carrier with an iron-containing solution under the action of ultrasonic waves, followed by drying, roasting, A core-shell ferromolybdenum catalyst was formed.

[0023] The molar fraction of the solute in the ferric nitrate solution is 1.0-5.0 mol / L, and the solvent is water, ethanol or acetone.

[0024] The molybdenum trioxide is a mesoporous material with a large specific surface and is dried at 100-120° C. for 0.5-3.0 hours before use.

[0025] The process of impregnating the molybdenum carrier with the iron-containing solution is: adding molybdenum trioxide to the ferric nitrate solution or adding the ferric nitrate solution dropwise into the molybdenum trioxide.

[0026] The power of the ultrasonic wave is 50-100W, and the vibration ...

Embodiment 1

[0034] Dry molybdenum trioxide at 105°C for 2.0h; prepare a 4.5mol / L aqueous solution of ferric nitrate; weigh 30.0g of dried molybdenum trioxide and place it in an ultrasonic oscillator with a power setting of 100W, and add 15.4mL of Ferric nitrate solution; dry the impregnated carrier without solution on the surface at 100°C for 15 hours; then calcinate at 600°C for 1 hour to obtain the core-shell structure ferromolybdenum catalyst.

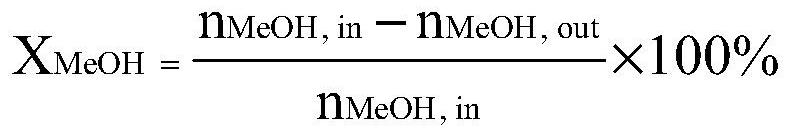

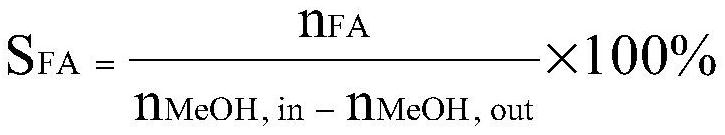

[0035] The catalyst is used in the oxidation of methanol to formaldehyde at a reaction temperature of 298°C. After the tail gas is absorbed by water, trace amounts of carbon monoxide and carbon dioxide are analyzed. Methanol and formaldehyde in the absorption liquid are detected on the Agilent chromatogram, and the obtained data are calculated according to the following formula Catalyst performance indicators:

[0036]

[0037]

[0038]

[0039]

[0040] Y FA= x MeOH ×S FA

[0041] Note: X MeOH —Methanol conversion rate per pas...

Embodiment 2

[0045] Dry molybdenum trioxide at 120°C for 2.5h; prepare 3.6mol / L ethanol solution of ferric nitrate; weigh 30.0g of dry molybdenum trioxide and place it in an ultrasonic oscillator with a power setting of 90W, and add 29.0mL nitric acid to it Iron solution; the impregnated carrier without solution on the surface is dried at 80°C for 8 hours; then calcined at 450°C for 2 hours to obtain the molybdenum-iron catalyst with core-shell structure.

[0046]The catalyst was used in the reaction of methanol oxidation to formaldehyde at a reaction temperature of 340°C, and the following performance data were obtained through gas-liquid phase product analysis and experimental data calculation:

[0047] X MeOH / %

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com