Immobilized catalyst for purifying cyclosiloxane

An immobilized catalyst, cyclosiloxane technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, solid adsorbent liquid separation, etc. Siloxane removal method and other issues, to achieve the effect of increased contact time and area, good affinity adsorption, and efficient selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

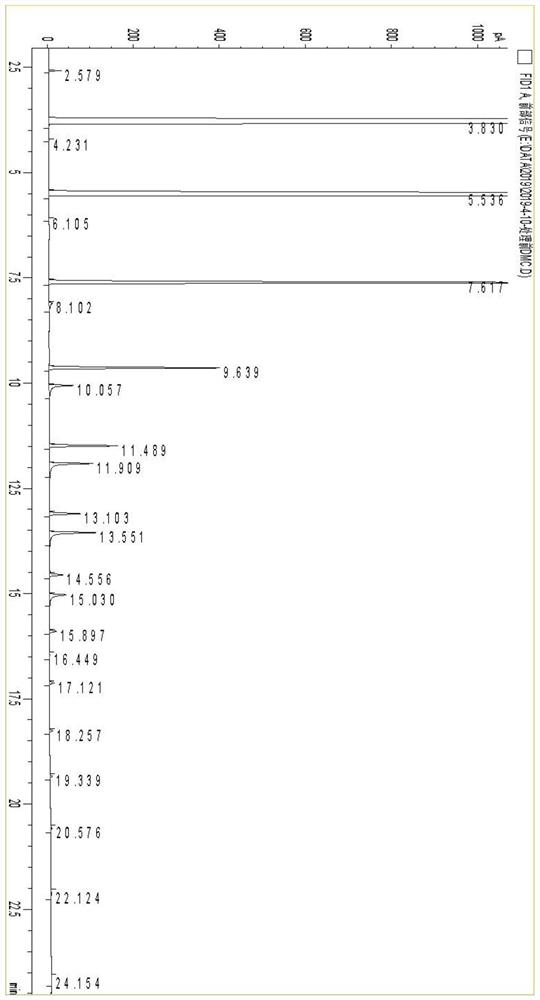

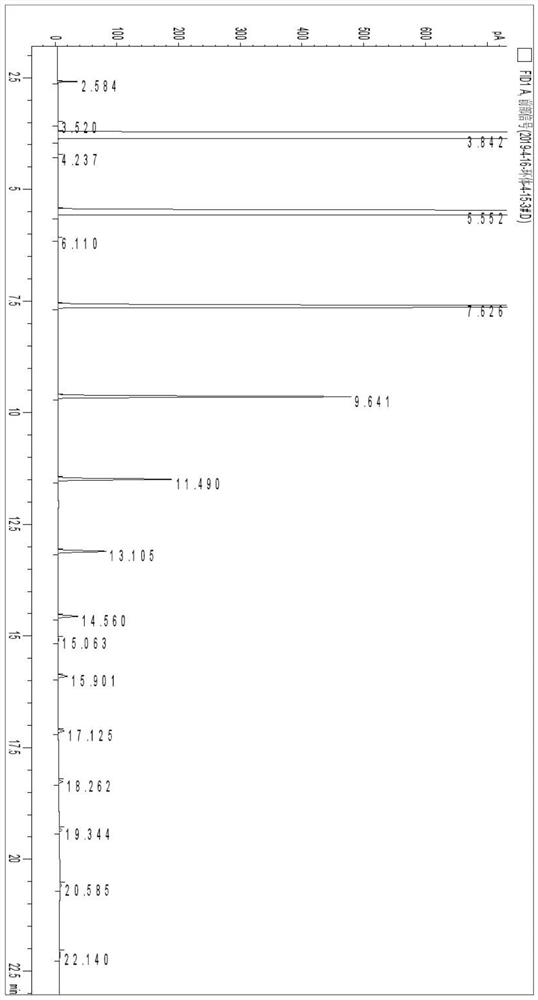

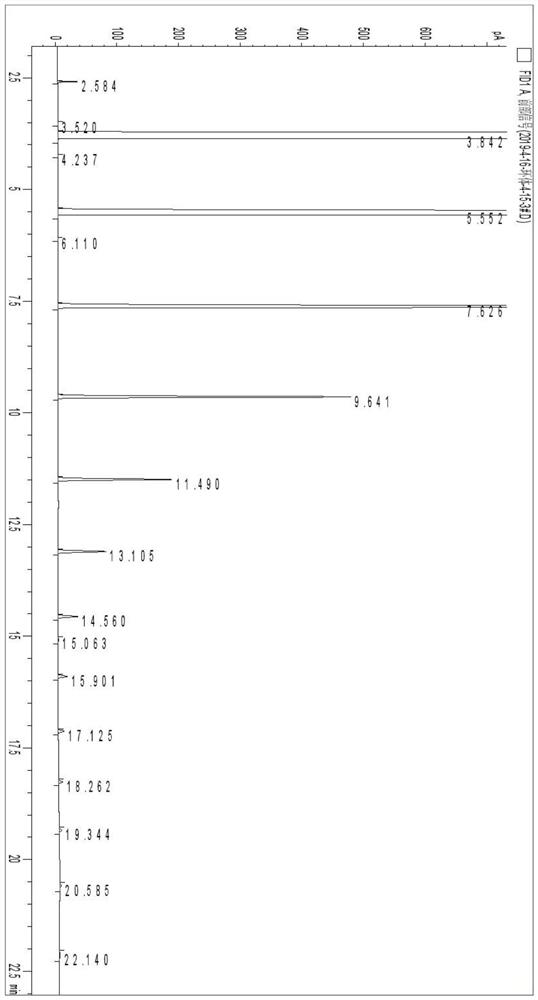

Image

Examples

preparation example 1

[0045] The preparation method of modified organic divalent metal 1 is as follows: in a 500ml three-necked bottle, mix 50mmol of monobutyltin oxide and 200mmol of hexanoic acid, stir at 100°C for 3h and use a water separator to remove the generated water in time Separation, and then filtered while hot to obtain the modified organic divalent metal 1.

preparation example 2

[0047]The preparation method of the modified organic divalent metal 2 is as follows: in a 500ml three-necked bottle, mix 50mmol of monotetradecyl zinc oxide and 220mmol of octanoic acid, stir at 120°C for 3h and use a water separator to separate the resulting water Separated in time, and then filtered while hot to obtain the modified organic divalent metal 2.

preparation example 3

[0049] The preparation method of the modified organic divalent metal 3 is as follows: in a 500ml three-necked bottle, mix 50mmol of monooctyltin oxide and 210mol of dodecanoic acid, stir at 110°C for 3h and use a water separator to separate the resulting water Separated in time, and then filtered while hot to obtain the modified organic divalent metal 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com