Large-Scale Adsorbent Modification Coupled Injection System for Controlling the Emission of Heavy Metal Pollutants in Flue Gas

A pollutant discharge and adsorbent technology, which is applied in the field of large-scale adsorbent modification coupled injection systems, can solve the problems of high moisture content of adsorbents, low degree of automation, accumulation time agglomeration, etc., and achieves good results and no dust flying. Overflow, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

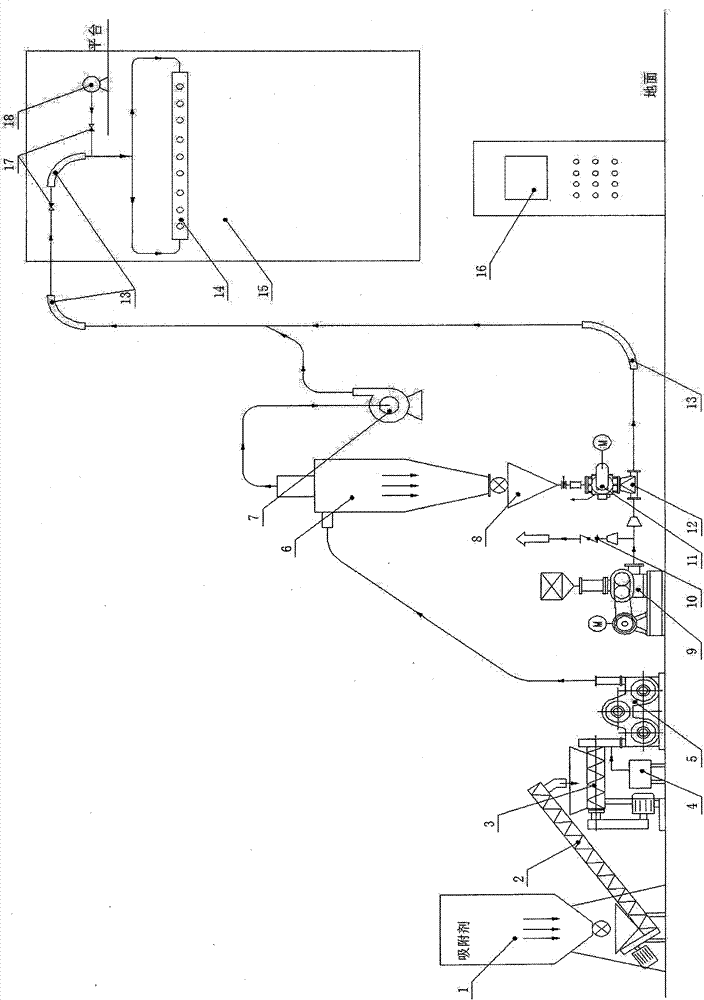

[0028] The present invention proposes a large-scale adsorbent modified coupling injection system, such as figure 1 As shown, it includes: adsorbent storage tank 1, rotary feeder 2, frequency conversion feeding device 3, modified agent tank 4, modified host 5, cyclone separator 6, induced draft fan 7, collecting hopper 8, Roots Fan 9, emptying valve 10, feeder 11, gas-solid mixing accelerator 12, delivery elbow 13, injection pipe 14, flue 15, electric control system 16, check valve 17 and air compressor 18. The system includes two parts: a large-scale modification system and an injection system, and the two systems work together to ensure the continuity and sealing of the coupling system.

[0029] The large-scale modification system includes a feeding device and a modification and collection device. 1, 2, 3, and 4 form an adsorbent an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com