Method and device for the gravimetric and in-series distribution of solution

a gravimetric and in-series technology, applied in the direction of liquid bottling, packaging under special atmospheric conditions, weighing apparatus, etc., can solve the problems of reducing the service life of this means, slowing down the distribution further, and significant time loss, so as to increase the speed of the distribution of solutions, improve the continuity of delivery of solutions, and pour into containers more smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

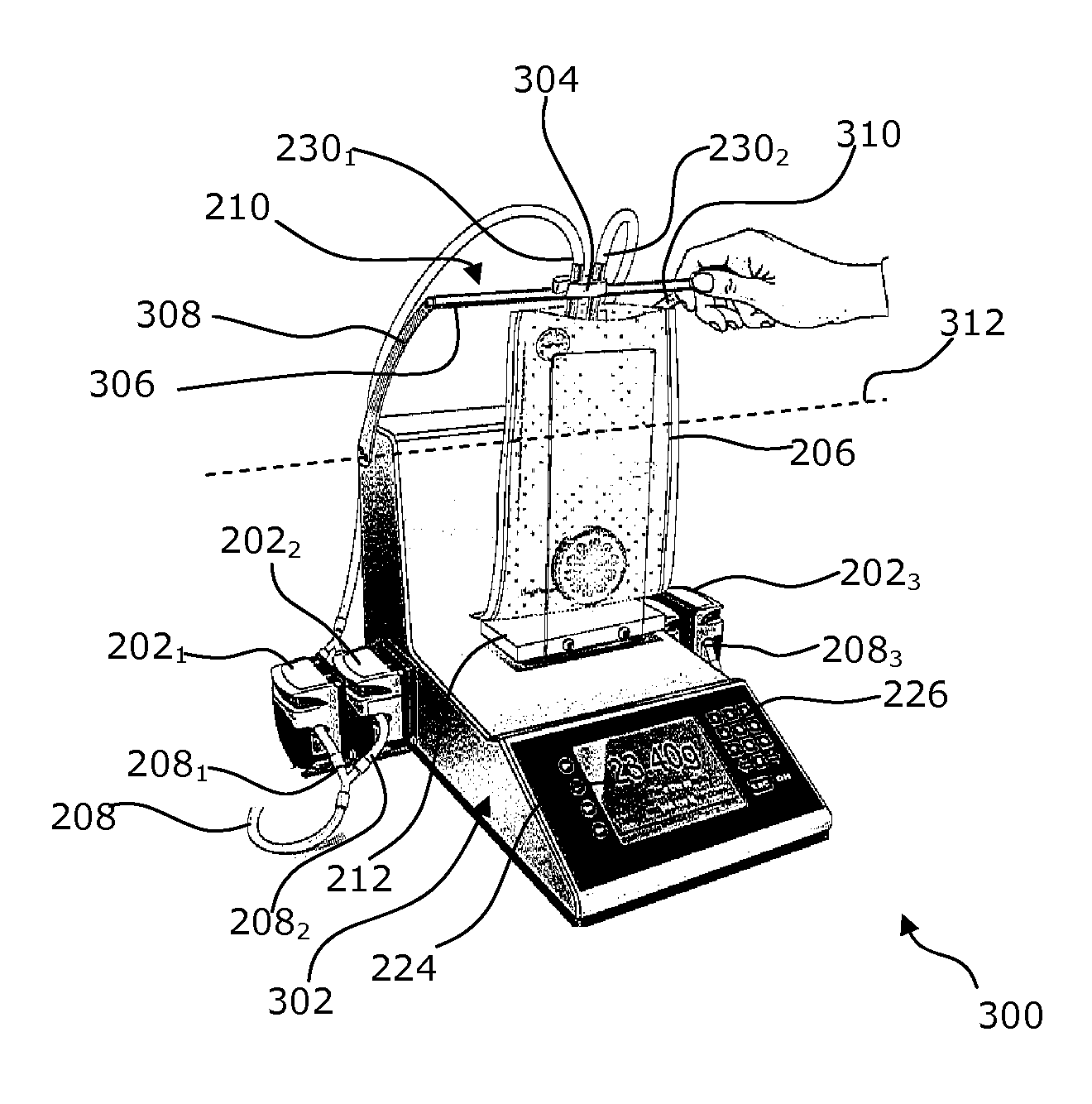

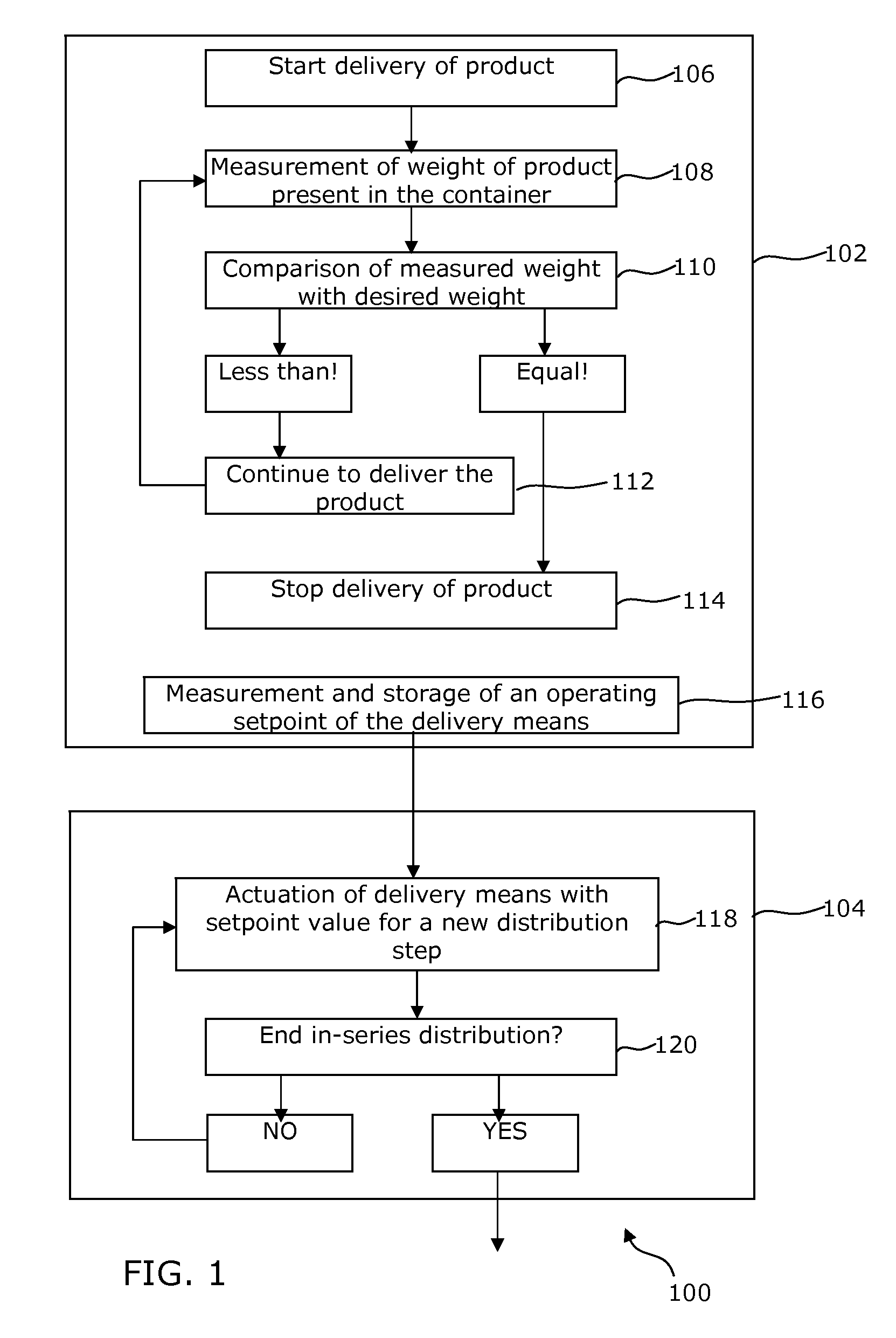

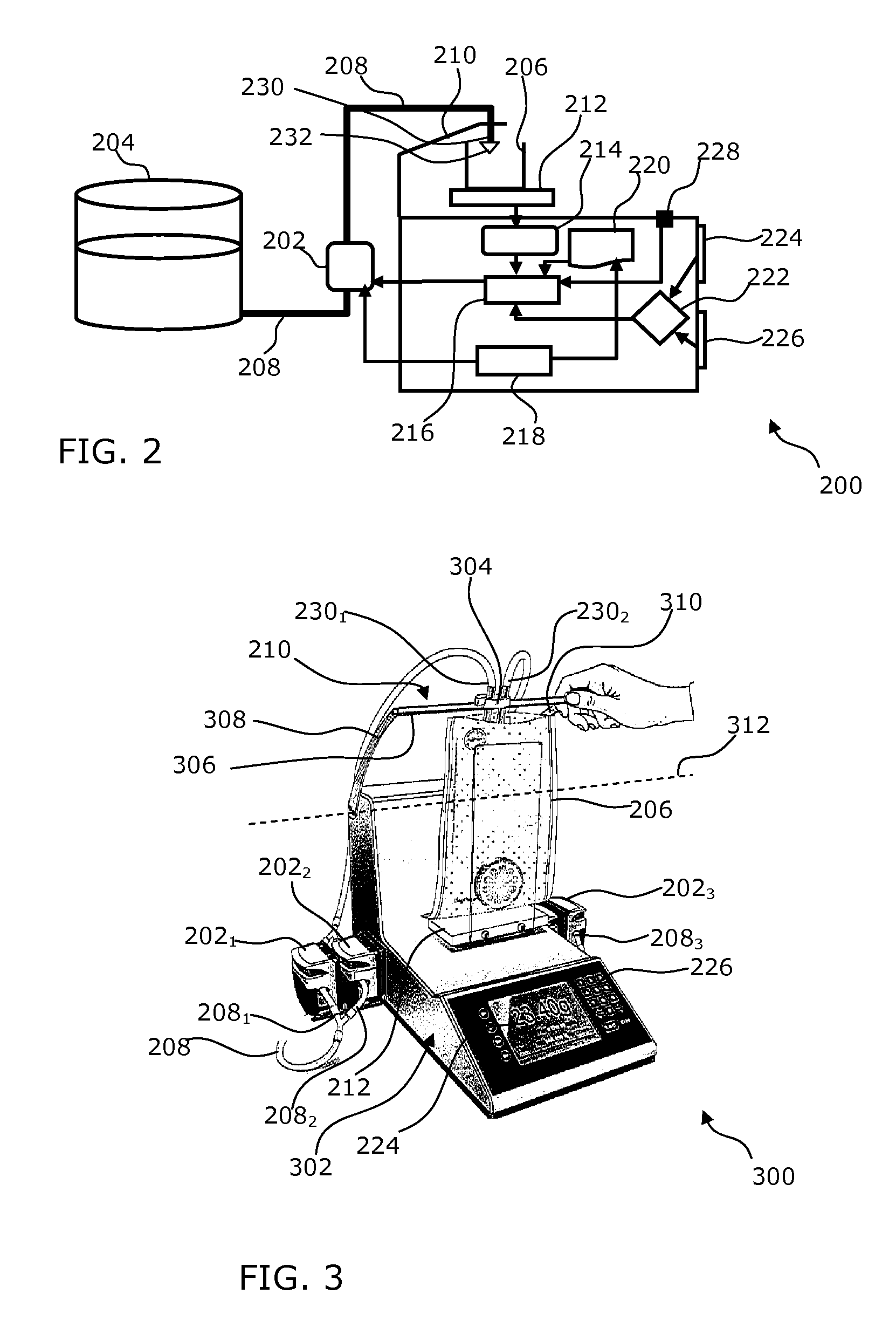

[0047]FIG. 2 is an exploded diagrammatic representation of a device 200 according to the invention. The device 200 comprises at least one non-contact delivery means 202 carrying out the delivery of a solution from a reservoir 204 as far as a container 206 through a delivery tube 208. The delivery means 202 can comprise one or more peristaltic pumps.

[0048]One of the ends of the delivery tube 208 is connected to the reservoir 204, and the other end is arranged on a support 210 that positions it over the container 206.

[0049]The device 200 has scales 212 on which the container 206 is arranged, and a module 214 is connected to the scales 212 and receives from the scales 212 a weight value corresponding to the weight of the solution present in the container 206. The module 214 is moreover arranged to compare the measured weight value with a desired weight value corresponding to a predetermined quantity of solution to be delivered into the container 206.

[0050]The module 214 is connected to...

second embodiment

[0061]FIG. 4 is a diagrammatic representation of a device 400 according to the invention. The device 400 shown in FIG. 4 comprises all the components of the device 200 of FIG. 2. In the device 400, the support 210 is mounted mobile in the three spatial directions. The device 400 also has motorization means 402 that can be actuated. The motorization means 402 can comprise one or more motors, for example stepper motors and one or more belts or slides that can move a holding element for the pouring end in two or three spatial dimensions to position it over a particular container in turn. The motorization means 402 are connected to the actuation module 216, which actuates these means 402 as a function of data received by the planning module 222.

[0062]FIG. 5 is a diagrammatic representation of a second example of a device 500 according to the invention carrying forth the embodiment of FIG. 4. The device 500 shown in FIG. 5 is presented in the form of a unitary piece assembly with a body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com