Mass transfer tray

A material exchange and tray technology, applied in chemical/physical processes, separation methods, chemical instruments and methods, etc., can solve the problems of uneven gas-liquid foam layer, insufficient effectiveness, and vacancies, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

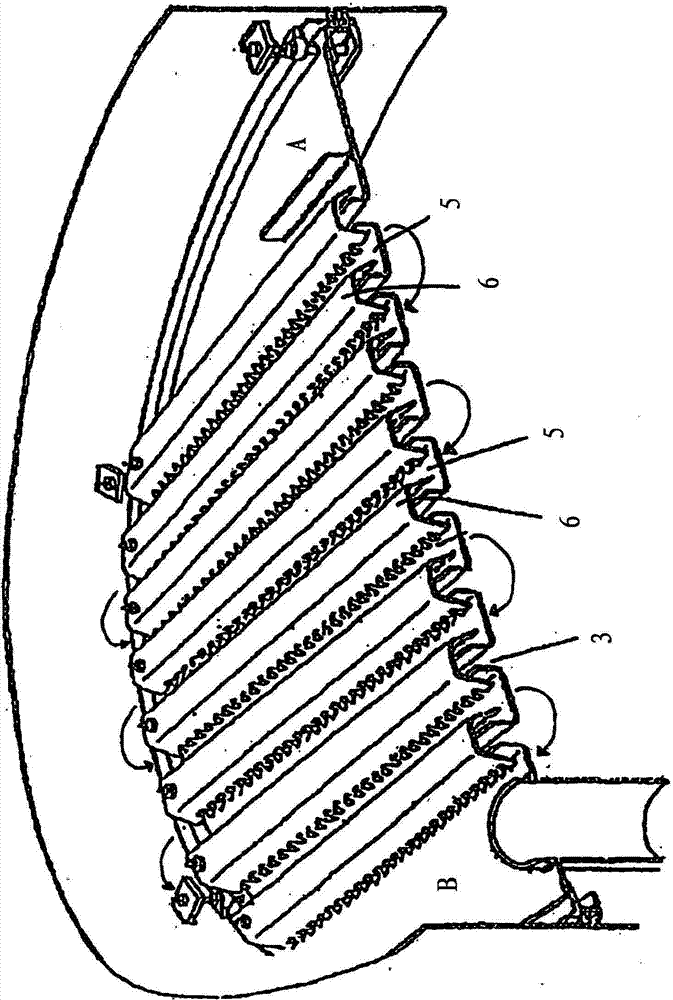

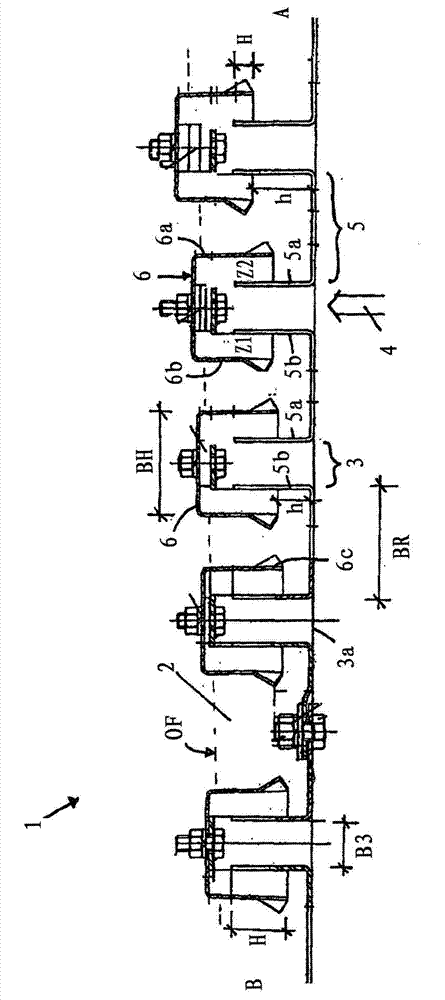

[0015] The mass exchange trays 1 according to the invention are installed horizontally in the column arrangement, wherein a plurality of trays 1 are arranged one above the other at a distance from each other. On each tray there is a liquid layer 2 through which the gas 4 flows from below through the gas passage gaps 3 . As a result, a gas-liquid foam layer consisting of liquid and gas bubbles forms above the tray 1 , in which gas-liquid foam layer an exchange of substances takes place. The liquid flows onto the tray on one side (inlet side A) on the edge of tray 1 in order to flow through the entire tray and exits on the other side (outlet side B) on the edge of the tray in order to reach the The tray below.

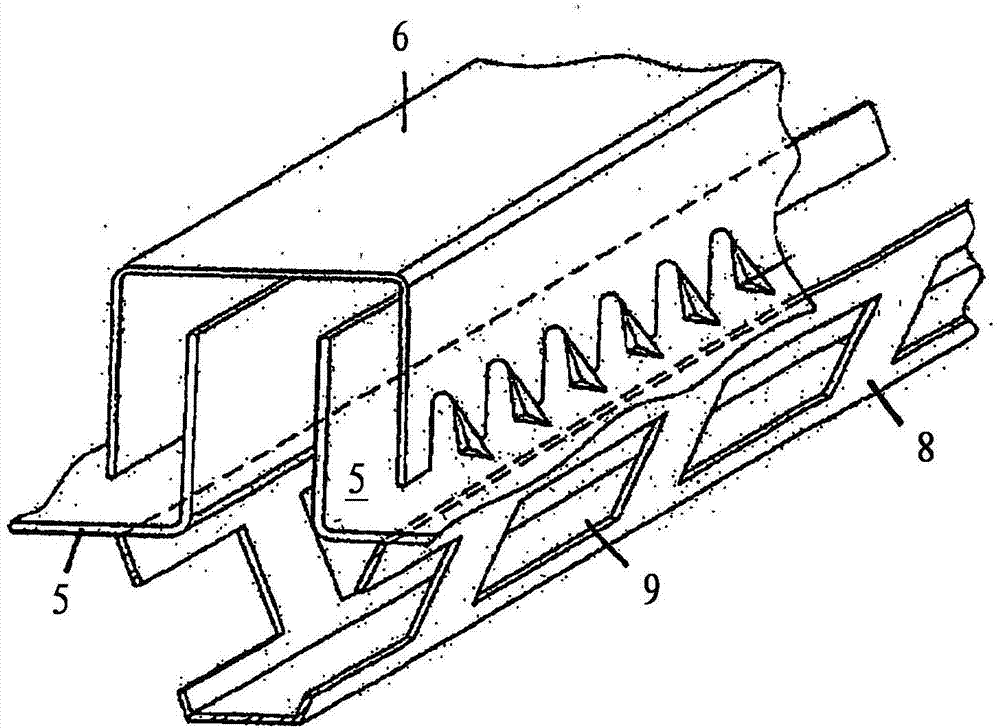

[0016] Between the inlet side A and the outlet side B, the tray consists of a plurality of mutually parallel, U-shaped profile-shaped grooves 5 in cross section, which form gas passage gaps 3 between them. Here, mutually facing, adjacent, vertical side walls 5 a , 5 b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com