Organic electroluminescent device

An electroluminescence device and luminescence technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of color shift, low luminous brightness of red sub-pixels and green sub-pixels, achieve mature technology and reduce lateral migration , Enhance the effect of the partition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

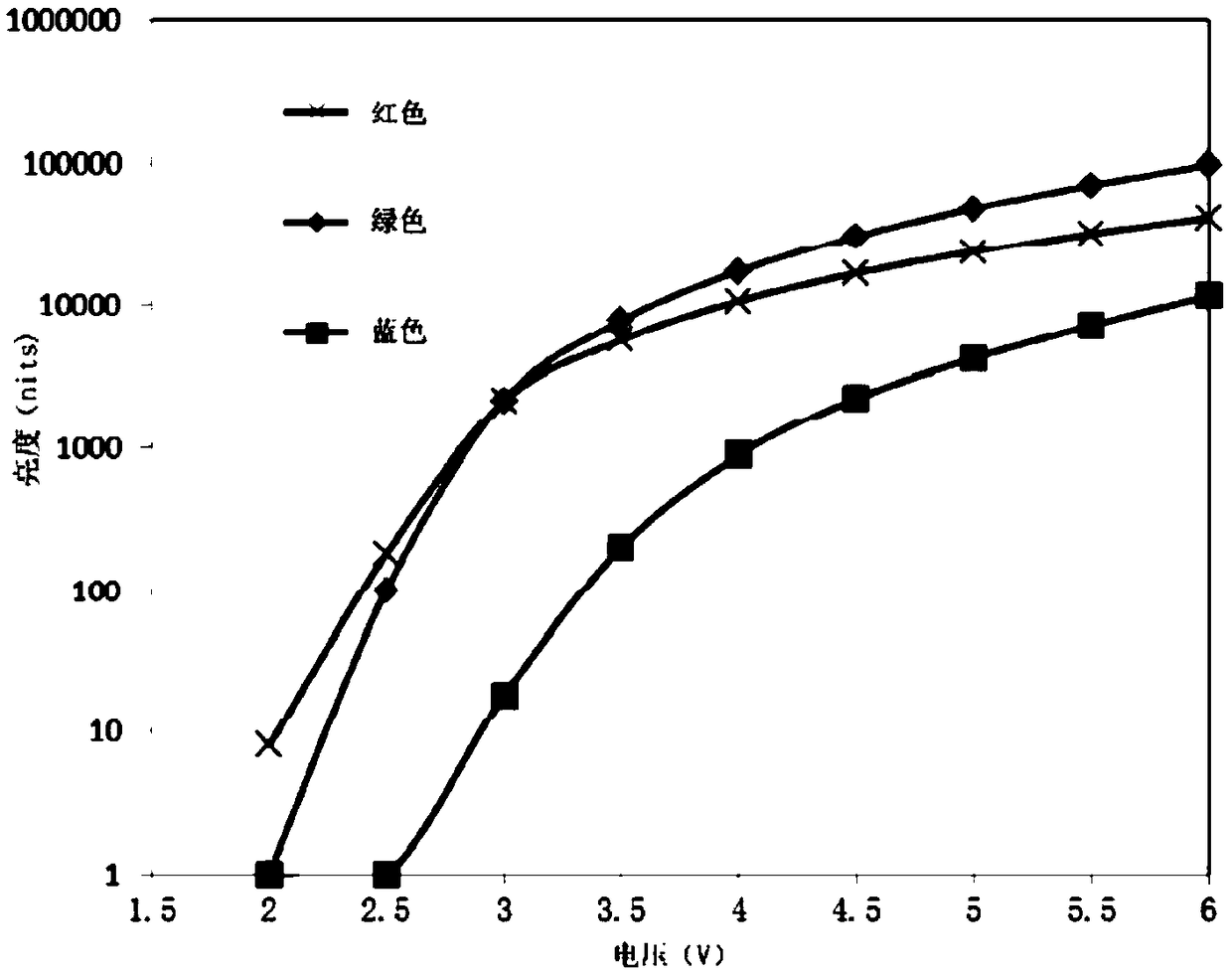

Embodiment 1

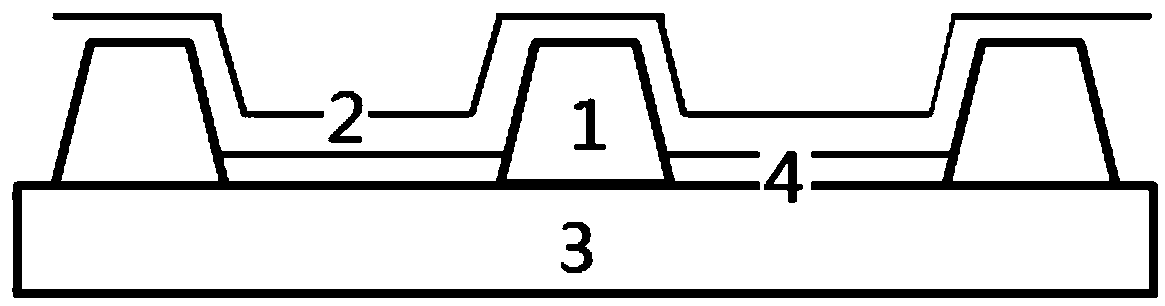

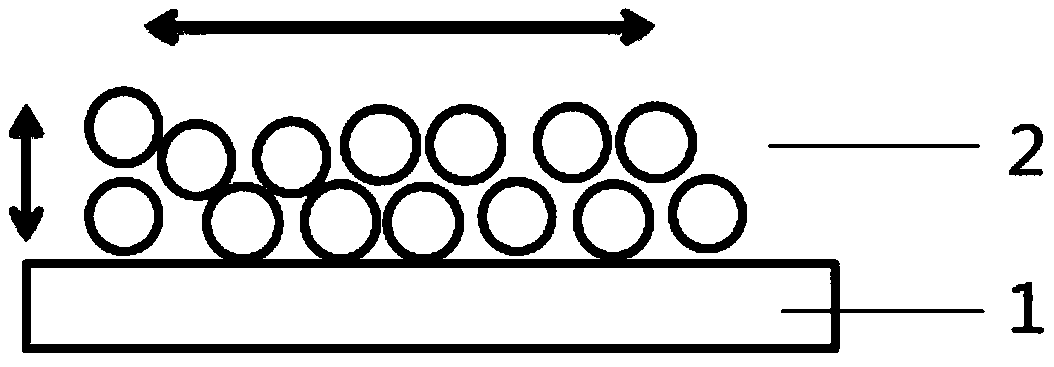

[0053] This embodiment provides an organic electroluminescent device, such as Figure 4 As shown, it includes a pixel defining layer 1 disposed on a substrate 3 , and a groove 11 for accommodating a sub-pixel unit is opened in the pixel defining layer 1 . In the organic electroluminescent device provided in this embodiment,

[0054] The device structure of the red sub-pixel unit is: ITO(10nm) / Ag(100nm) / ITO(10nm) / CuPc(20nm) / TPD(200nm) / CBP:Ir(piq) 3 (3%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm);

[0055] The device structure of the green photosub-pixel unit is: ITO(10nm) / Ag(100nm) / ITO(10nm) / CuPc(20nm) / TPD(150nm) / CBP:Ir(ppy) 3 (10%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm);

[0056] The blue light sub-pixel unit device structure is: ITO(10nm) / Ag(100nm) / ITO(10nm) / CuPc(20nm) / TPD(120nm) / CBP: Firpic(3%,30nm) / TPBi(40nm) / LiF( 1nm) / Mg:Ag(20%,15nm) / NPB(60nm);

[0057] The pixel definition layer 1 is polyvinyl alcohol, and the static contact angle between poly...

Embodiment 2

[0059] This embodiment provides an organic electroluminescent device, the structure of which is the same as that of Embodiment 1, except that figure 2 As shown, the longitudinal section of the pixel defining layer 11 is a regular trapezoid, the side length of the upper and lower bottom surfaces is 22um, the height is 1.5um, and the angle between the bottom surfaces is 150°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com