Factory and mine lighting lamp with LED lighting sources turned on alternately

A technology of LED light source and lighting lamp, applied in the direction of light source, electric light source, lighting application, etc., can solve the problem of shortening the service life of LED lamp, and achieve the effect of prolonging the service life, reducing the accumulation of heat, and avoiding lighting at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

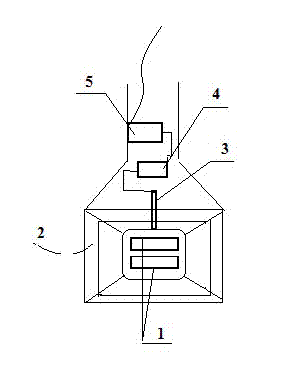

[0011] like figure 1 As shown, the factory and mine lighting lamp with LED light sources alternately lit by the present invention includes an LED light source assembly and a base, and a thermosensitive element, a thermoelectric signal conversion device, and a circuit control module are arranged in the base, and the thermosensitive element converts a thermoelectric signal The device is connected with the circuit control module, and the sensing end of the thermal element is connected with the LED light source.

[0012] There are two LED light source components, which are respectively electrically connected to the circuit control module and alternately lighted.

[0013] When the power is turned on, one of the LED light source components lights up, and the thermosensitive element senses the temperature in the base, and outputs a thermal signal, which is converted into an electrical signal by the thermoelectric signal conversion device. The higher the temperature, the stronger the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com