Organic light emitting device

An electroluminescence device and luminescence technology, applied in the direction of circuits, electrical components, electric solid-state devices, etc., can solve the problems of low luminance and color shift of red photon sub-pixels and green photon sub-pixels, achieve good transmission performance, and improve low gray Color gradients, reducing the effect of lateral migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

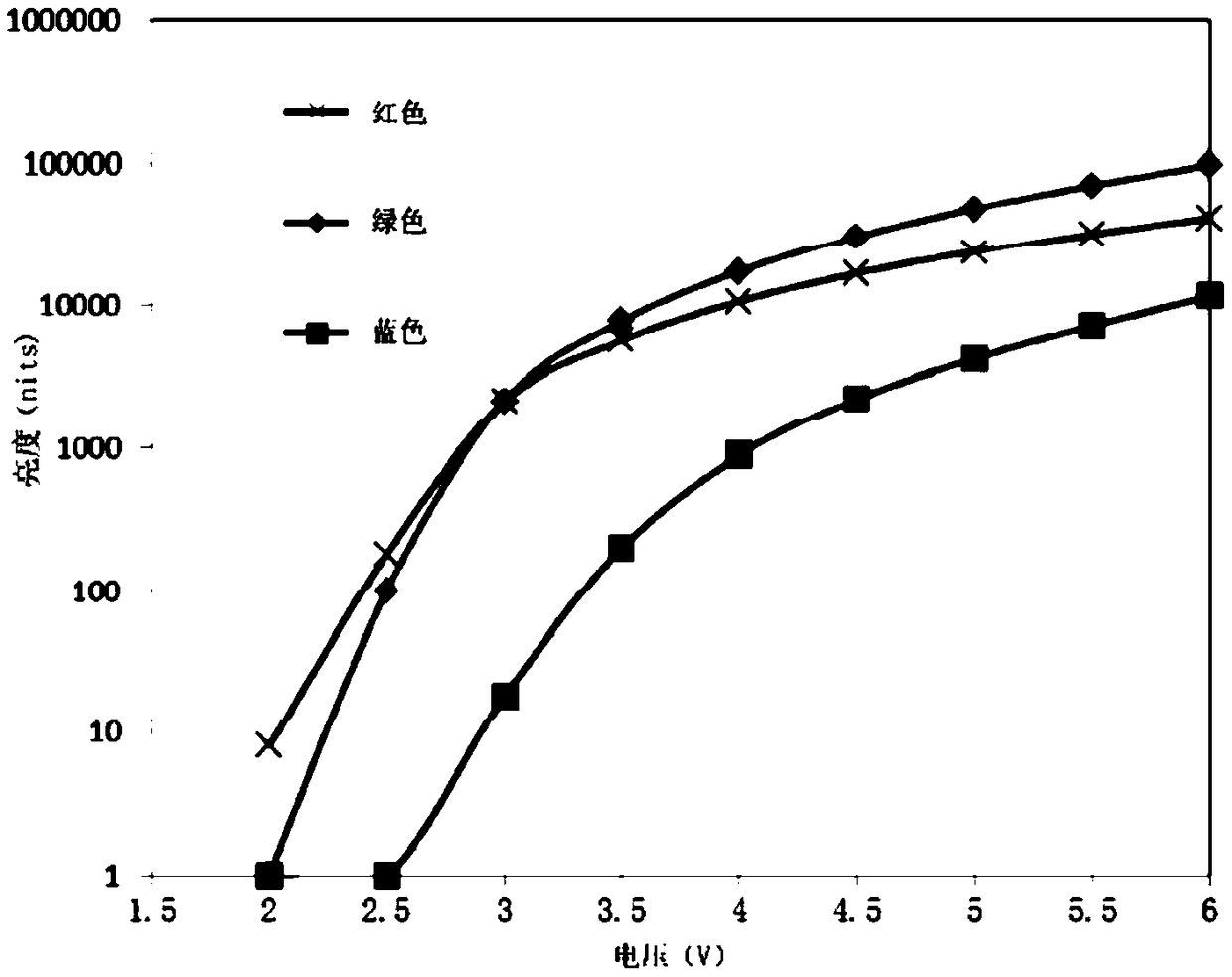

[0067] This embodiment provides a specific example of an organic electroluminescence device, which includes several pixel units distributed in an array, and the pixel units include a red sub-pixel unit 1R, a green sub-pixel unit 1G and a blue sub-pixel unit 1B.

[0068] The red sub-pixel unit 1R includes an anode, a hole injection layer, a light-emitting layer 13, an electron injection layer, and a cathode that are stacked in sequence, and the green sub-pixel unit 1G includes an anode, a hole injection layer, a light-emitting layer 13, and an electron injection layer that are stacked in sequence. layer and cathode, the blue light sub-pixel unit 1B includes an anode, a hole injection layer, a light emitting layer 13 , an electron injection layer and a cathode which are stacked in sequence.

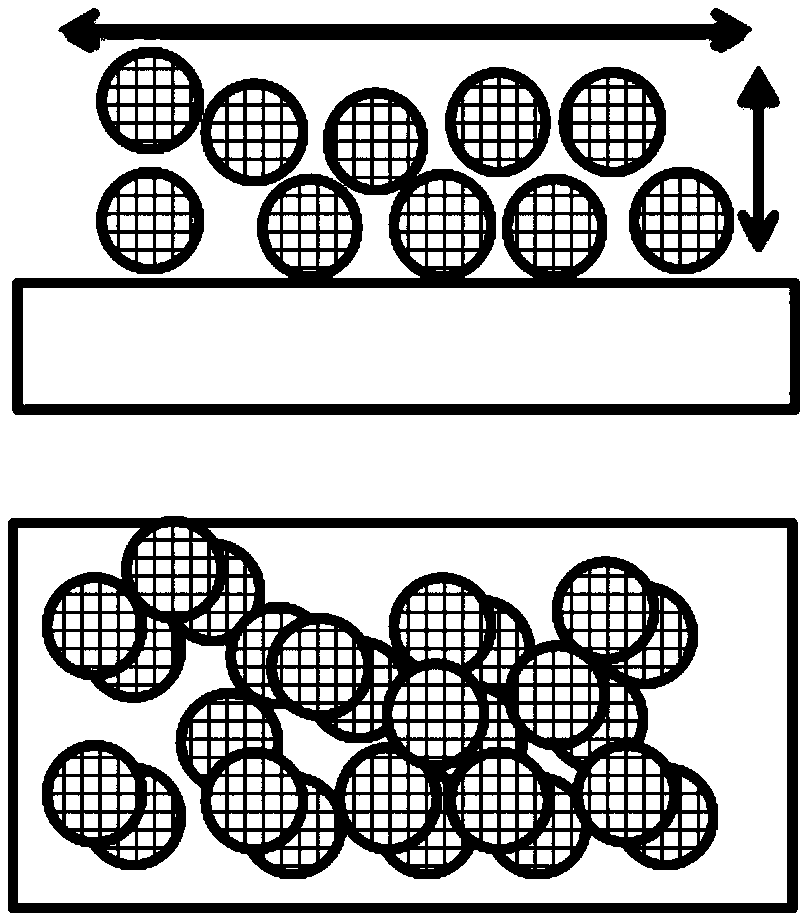

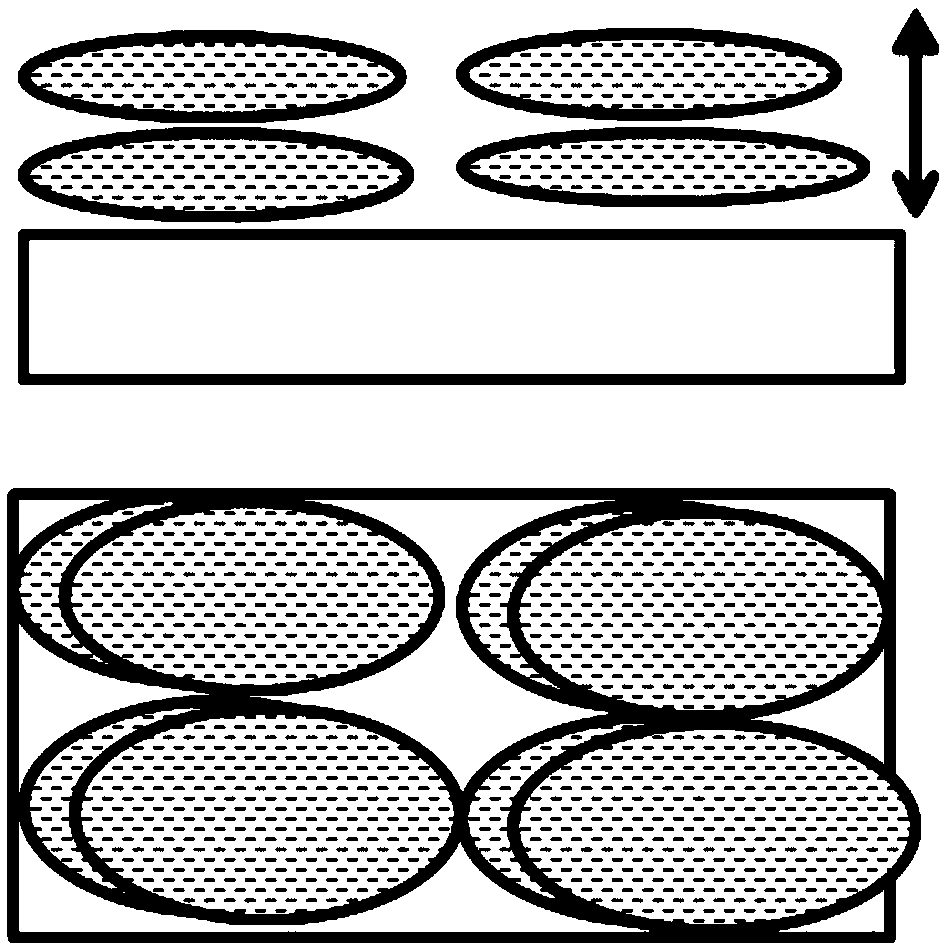

[0069] Among them, the hole injection layer of each sub-pixel unit is made of a compound with a planar molecular structure stacked along the direction perpendicular to the light-emitting lay...

Embodiment 2

[0074] This embodiment provides an organic electroluminescent device, which is basically the same as the organic electroluminescent device described in Example 1, the only difference being:

[0075] The hole injection layers of the red light sub-pixel unit 1R and the green light sub-pixel unit 1G are stacked in the direction perpendicular to the light-emitting layer 13 by using a compound with a planar molecular structure, and are staggered in a direction parallel to the light-emitting layer 13. The specific molecular structure compound is (TIPS-Pentacene).

[0076] The device structure of the red sub-pixel unit 1R in this embodiment is: ITO(10nm) / Ag(100nm) / ITO(10nm) / TIPS-Pentacene(10nm) / TPD(200nm) / CBP:Ir(piq) 3 (3%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm).

[0077] The device structure of the green sub-pixel unit 1G in this embodiment is: ITO(10nm) / Ag(100nm) / ITO(10nm) / TIPS-Pentacene(10nm) / TPD(160nm) / CBP:Ir(ppy) 3 (3%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / ...

Embodiment 3

[0080] This embodiment provides an organic electroluminescent device, which is basically the same as the organic electroluminescent device described in Example 1, the only difference being:

[0081] Specifically, the compound having a planar molecular structure in each sub-pixel unit is: iron phthalocyanine (abbreviation: FePc).

[0082] The device structure of the red sub-pixel unit 1R in this embodiment is: ITO(10nm) / Ag(100nm) / ITO(10nm) / FePc(10nm) / TPD(200nm) / CBP:Ir(piq) 3 (3%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm).

[0083] The device structure of the green sub-pixel unit 1G in this embodiment is: ITO(10nm) / Ag(100nm) / ITO(10nm) / FePc(10nm) / TPD(160nm) / CBP:Ir(ppy) 3 (3%, 30nm) / TPBi(40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm).

[0084] The device structure of the blue light sub-pixel unit 1B in this embodiment is: ITO (10nm) / Ag (100nm) / ITO (10nm) / FePc (10nm) / TPD (120nm) / CBP: Firpic (3%, 30nm) / TPBi (40nm) / LiF(1nm) / Mg:Ag(20%, 15nm) / NPB(60nm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com