Single-sided four-track plain weaving machine

A four-track, plain weave machine technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of increased difficulty, difficulty in changing, waste of raw materials, etc., and achieve less difficulty in operation, less loss of mechanical energy, and better fabric quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

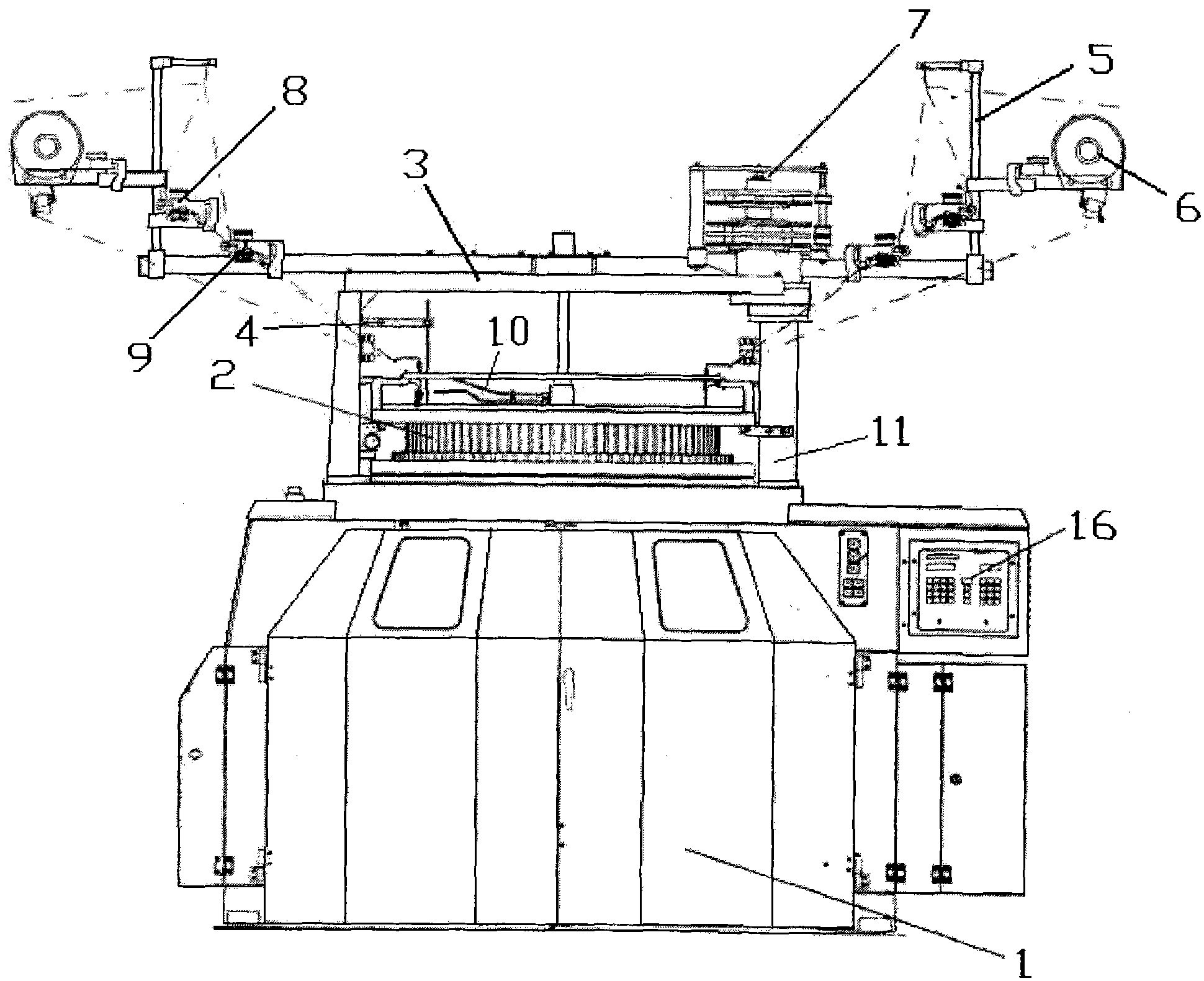

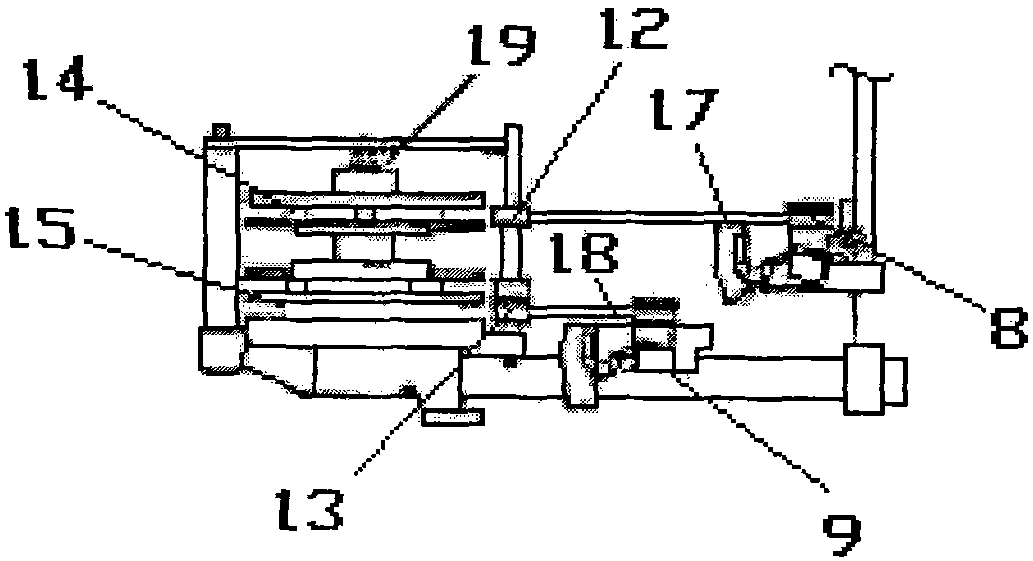

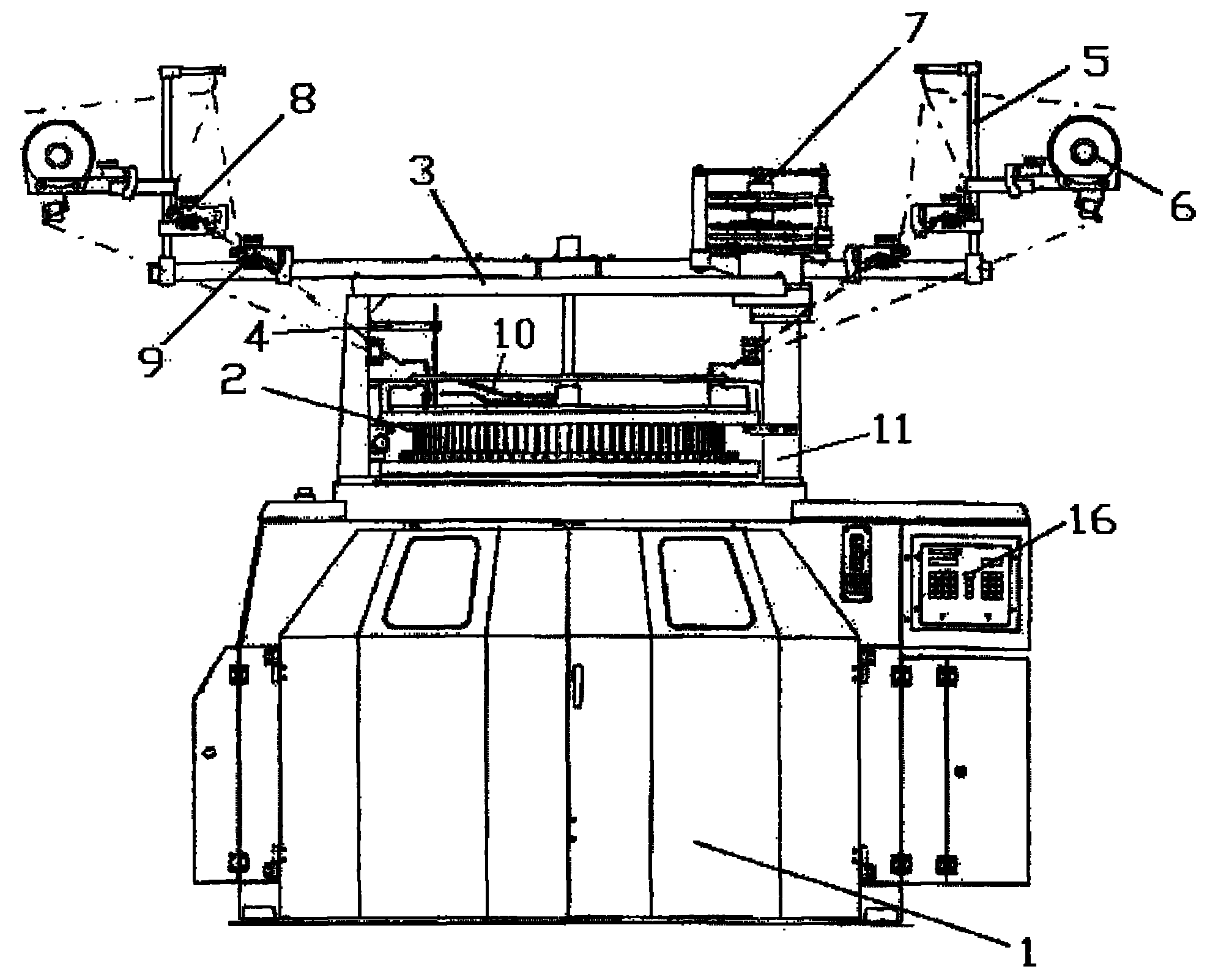

[0018] Such as figure 1 , 2 As shown, the present embodiment consists of a box body 1, a triangular return stitch device 2, a support frame 3, a yarn guide 4, an upper thread feeding device 5, a lower thread feeding device 6, a wire feeding row 7, an upper wire feeding wheel 8, a lower wire feeding device Line transmission wheel 9, dust blowing pipe 10 and power shaft 11 form. The triangular return stitch device 2, the power shaft 11 and the support frame 3 are installed above the box body 1, the upper wire feed device 5 and the lower wire feed device 6 are installed on the support frame 3, the upper wire feeding wheel 8, and the lower wire feeding wheel 9 Installed on the support frame 3 at positions corresponding to the upper line feeder 5 and the lower wire feeder 6 . The yarn guide 4 is installed on the support frame 3, and the position of the yarn guide 4 matches the positions of the upper thread feeder 5 and the lower thread feeder 6. The controller 16 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com