Gearbox speed changer lubricant composition as well as preparation method and application thereof

A lubricant composition and transmission technology, applied in the direction of lubricating composition, petroleum industry, etc., to achieve the best fluidity and transmission performance, improve uniform dispersion, and increase the effect of anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

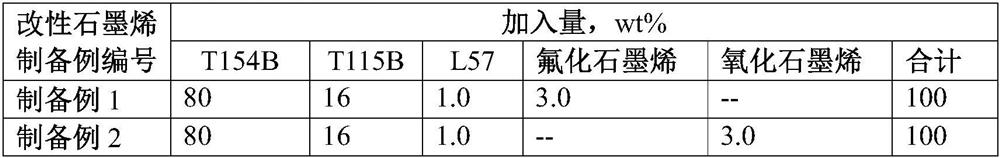

[0040] The preparation example of the modified graphene described in the present invention is prepared by blending the components shown in the following table 1 in weight percentage.

[0041] Table 1 Modified graphene preparation example formula

[0042]

[0043]Stir 80wt% T154B and 16wt% T115B at 45°C and 350r / min for 40min, then add 3.0wt% fluorinated graphene to the above mixture, and ultrasonically disperse at 45°C for 30min to obtain modified graphite Alkene Preparation Example 1.

[0044] Stir 80wt% T154B and 16wt% T115B at 45°C and 350r / min for 40min, then add 3.0wt% graphene oxide to the above mixture, and ultrasonically disperse at 45°C for 30min to obtain modified graphene Preparation Example 2.

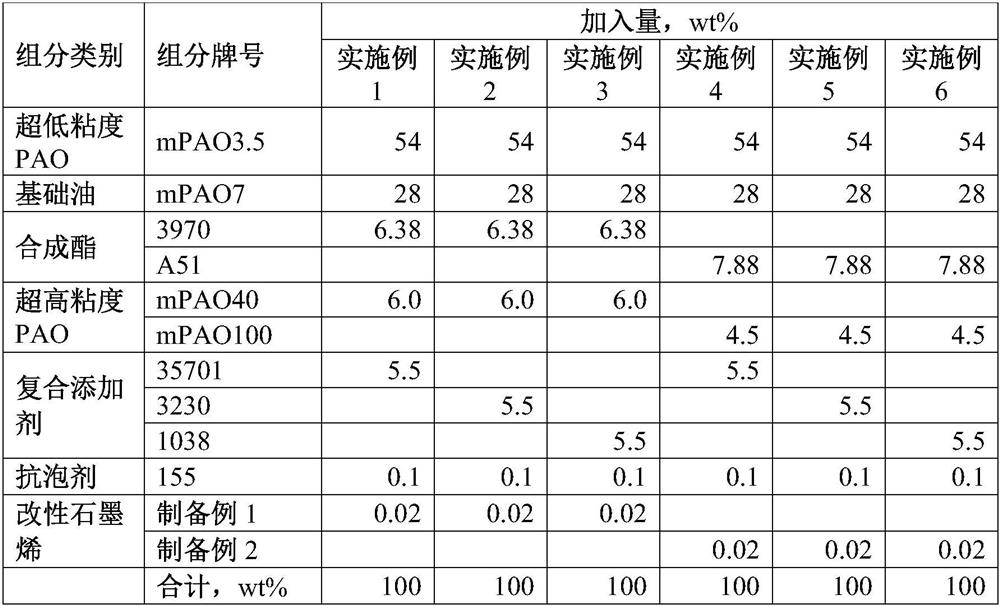

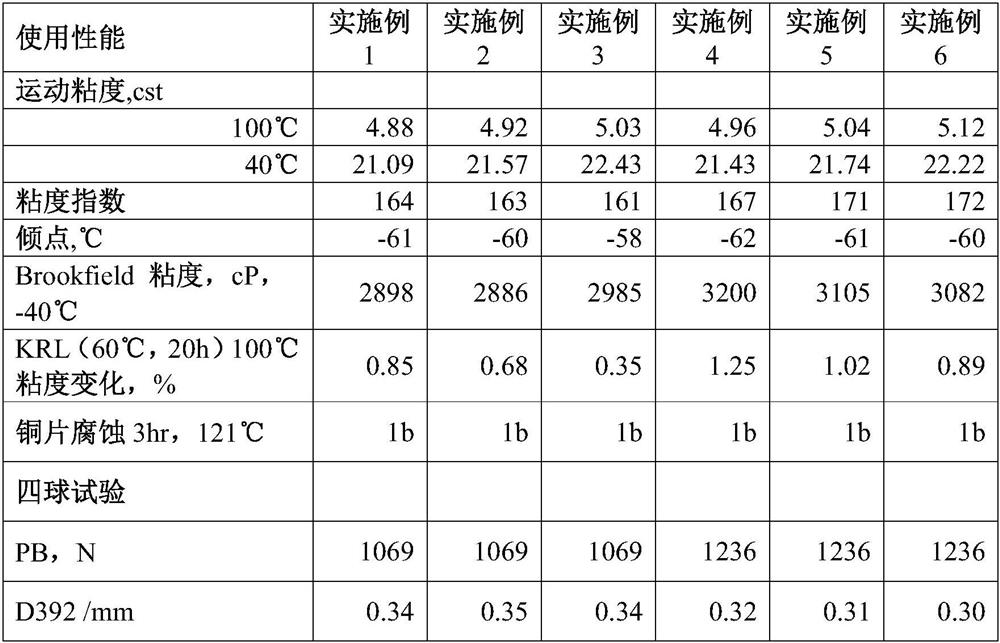

[0045] Gearbox Transmission Lubricant Examples 1-6

[0046] The composition and dosage of the automotive gearbox transmission oil in this application example are shown in Table 2 below:

[0047] Table 2 Composition and blending formula of automotive gearbox transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com