Carbon nanomaterial with high grafting rate, and preparation method thereof

A technology of carbon nanomaterials and high grafting rate, applied in the direction of nano-carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of difficulty in uniform dispersion, unmentioned grafting rate, unmentioned, etc., and meet the reaction conditions Mild, large-scale application convenience, simple process operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

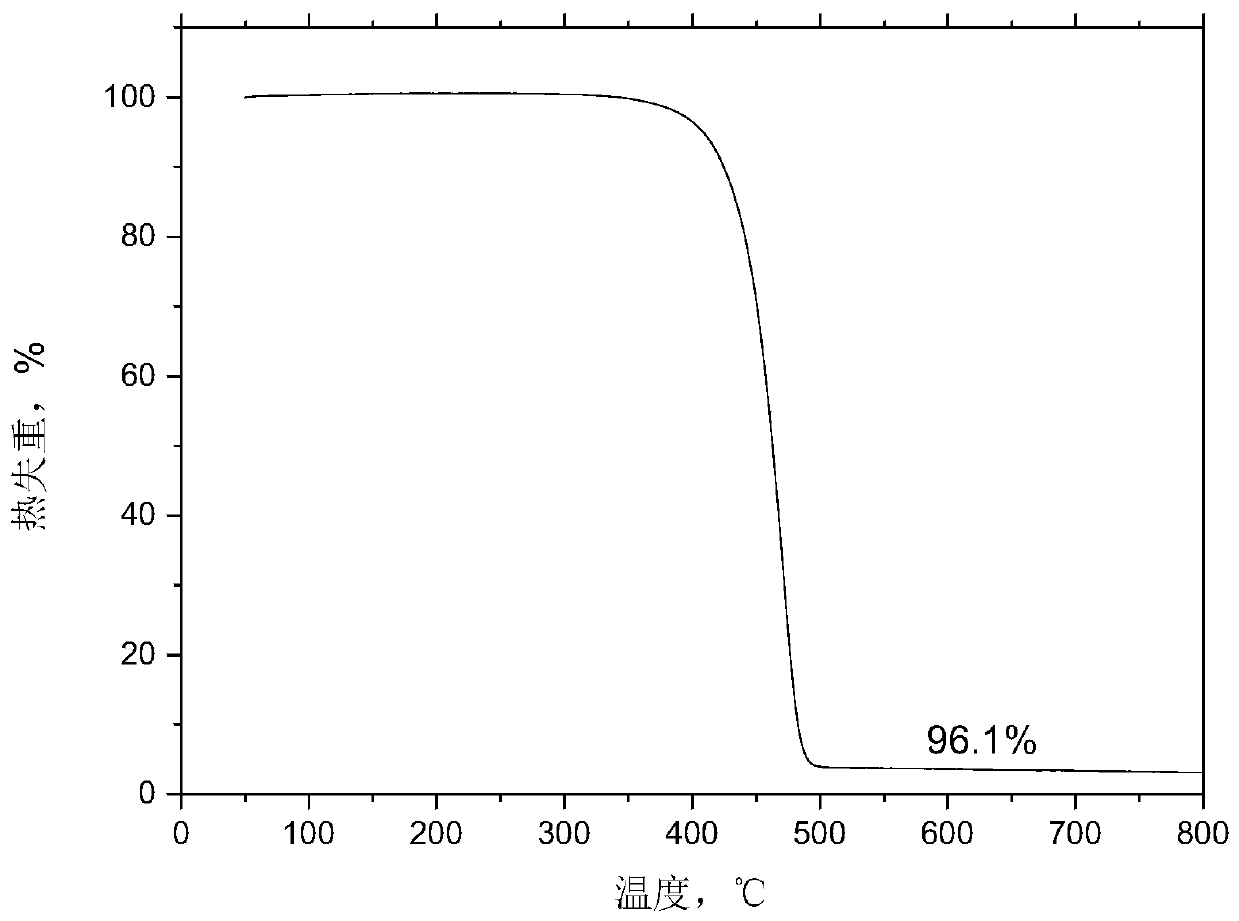

[0021] Add graphene oxide aqueous solution in polytetrafluoroethylene reaction container, concentration is 3%, add LiOH · H O, mass is 50% of graphene oxide. Ultrasound at 250W for 1 hour, during which carbon dioxide was continuously injected. After sonication, heat to 95°C, keep stirring for 6h and then cool naturally. The hydration reaction was carried out with 2.5kPa water vapor for 30min, filtered, washed, and vacuum-dried at 80°C, the graphene oxide was reduced, and graphene with a high grafting rate was obtained. After polymer grafting, the grafting rate reached 96.1%, such as figure 1 shown.

Embodiment 2

[0023] Add an aqueous solution of carbon nanotubes into a polytetrafluoroethylene reaction vessel with a concentration of 1%, and add LiOH·H2O so that the mass is 100% of the carbon nanotubes. Ultrasound at 250W for 2 hours, during which carbon dioxide was continuously injected. After the sonication, heat to 105°C, keep stirring for 6h and then cool naturally. The hydration reaction is carried out with 2.5kPa water vapor for 60min, after filtration, washing and vacuum drying at 80°C, carbon nanotubes with high grafting rate are obtained, and the average grafting rate of the polymer reaches more than 95%.

Embodiment 3

[0025] Add an aqueous solution of carbon nanotubes into a polytetrafluoroethylene reaction container with a concentration of 0.01%, and add LiOH·H2O, whose mass is 80% of the carbon nanotubes. 250W ultrasound for 1.5h, during which carbon dioxide was continuously injected. After the sonication, heat to 105°C, keep stirring for 6h and then cool naturally. Carry out hydration reaction with 2.5kPa water vapor for 60min, filter, wash, and vacuum dry at 80°C to obtain carbon nanotubes with high grafting rate, and the average grafting rate of the polymer is over 92%.

[0026] The invention utilizes lithium to defect the carbon nanometer material to provide a treatment method for increasing the grafting rate of the carbon nanometer material. The process is simple in operation, the reaction condition is mild, and the average grafting rate is above 90%. Efficient and convenient, it provides convenience for the large-scale application of carbon nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com