Multifunctional organic/inorganic compound fertilizer and preparation method thereof

A compound fertilizer and multi-functional technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as reduced work efficiency, excessive fertilizer release, and long cooling time, and achieves improved efficiency, reduced release, and increased productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

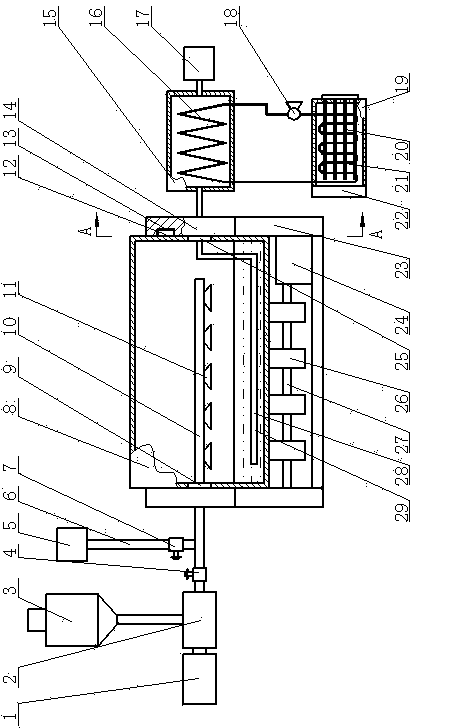

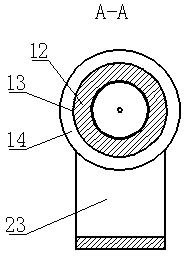

Image

Examples

Embodiment 1

[0019] A multifunctional organic-inorganic compound fertilizer, which is composed of the following raw materials in weight ratio: 30% urea, 5% monoammonium phosphate, 10% potassium sulfate, 30% humic acid, 3% zinc sulfate, and 0.1% microbial bacterial solution , diatomaceous earth 20% and sophorolipid 1.9%.

[0020] The humic acid of the present invention is obtained by activation treatment of weathered coal, and the specific operation steps are:

[0021] ①Pretreat the weathered coal in a hammer crusher for 2 hours to obtain pretreated weathered coal;

[0022] ②Add the pretreated weathered coal, nitric acid with a mass fraction of 65% and sodium 2-(dodecyl sulfoxide) ethyl sulfate into the mixer according to the mass ratio of 1:100:0.1 and stir. During the stirring process, chlorine gas is passed. The rate of chlorine gas in the solution is 10L / min, after stirring for 48h, it is centrifugally filtered to obtain humic acid.

[0023] The microorganism bacterium liquid of the p...

Embodiment 2

[0030] A multifunctional organic-inorganic compound fertilizer, which is composed of the following raw materials in weight ratio: 28% urea, 8% monoammonium phosphate, 16% potassium sulfate, 32% humic acid, 1.5% zinc sulfate, and 0.2% microbial bacterial solution , diatomaceous earth 12% and sophorolipid 2.3%.

[0031] The humic acid of the present invention is obtained by activation treatment of weathered coal, and the specific operation steps are:

[0032] ①Pretreat the weathered coal in a hammer crusher for 2 hours to obtain pretreated weathered coal;

[0033] ②Add the pretreated weathered coal, nitric acid with a mass fraction of 65% and sodium 2-(dodecyl sulfoxide) ethyl sulfate into the mixer according to the mass ratio of 1:125:1.25 and stir. Chlorine gas is passed during the stirring process. The rate of chlorine gas in the solution is 10L / min, after stirring for 48h, it is centrifugally filtered to obtain humic acid.

[0034] The microorganism bacterium liquid of the...

Embodiment 3

[0041] A multifunctional organic-inorganic compound fertilizer, which is composed of the following raw materials in weight ratio: 25% urea, 10% monoammonium phosphate, 18% potassium sulfate, 27% humic acid, 2% zinc sulfate, and 0.3% microbial bacterial solution , diatomaceous earth 15% and sophorolipid 2.7%.

[0042] The humic acid of the present invention is obtained by activation treatment of weathered coal, and the specific operation steps are:

[0043] ①Pretreat the weathered coal in a hammer crusher for 2 hours to obtain pretreated weathered coal;

[0044] ②Put the pretreated weathered coal, nitric acid with a mass fraction of 65% and sodium 2-(dodecyl sulfoxide) ethyl sulfate into the mixer according to the mass ratio of 1:150:0.5 and stir. During the stirring process, chlorine gas is passed. The rate of chlorine gas in the solution is 10L / min, after stirring for 48h, it is centrifugally filtered to obtain humic acid.

[0045] The microorganism bacterium liquid of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com