A porous film with vertical through channels, its manufacturing device and preparation method

A technology of porous film and through-hole channel, which is applied to chemical instruments and methods, devices for coating liquid on the surface, nickel compounds, etc., and can solve the problem that the minimum thickness cannot be less than 0.8 mm, vertical channels cannot be obtained, porous membrane is easily broken, etc. problems, to achieve the effect of facilitating the diffusion of substances, increasing the effective catalytic area, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Take a suspension of 8 mg / ml graphene oxide in water and ethanol and mix it uniformly with a volume ratio of 30:1, and ultrasonicate for 10 minutes to obtain a solid-liquid mixture;

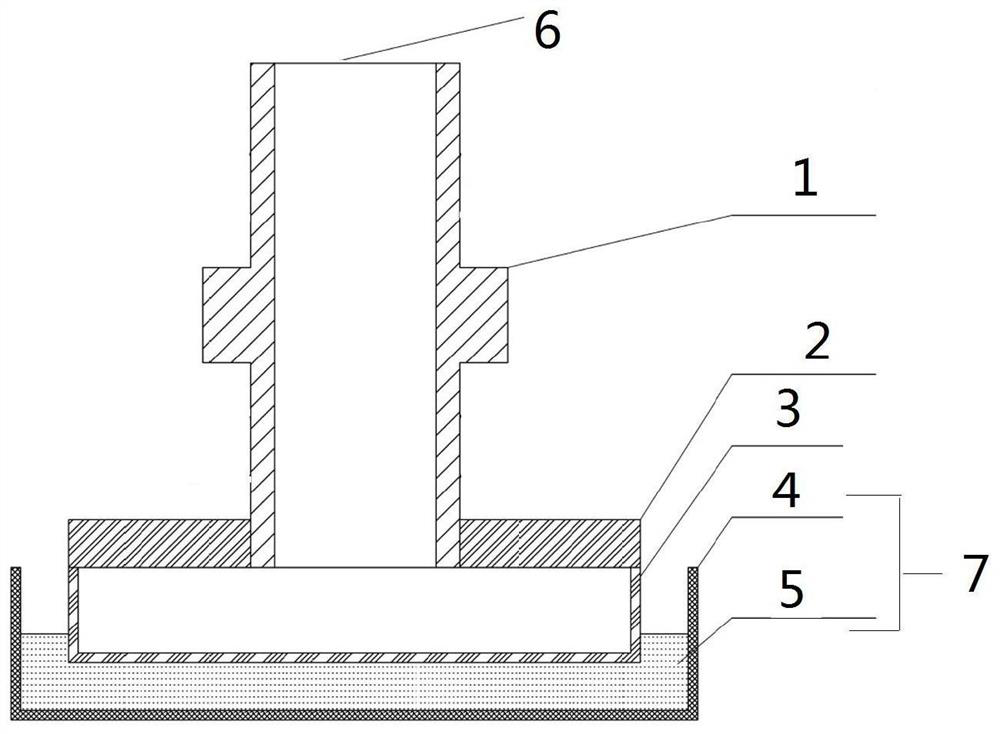

[0066] (2) use figure 1 The device uses ethanol as a refrigerant, turns on the freezing device to cool the ethanol to -60°C, turns on the rotating device and sets the rotation speed to 2600r / min, and waits for 15 minutes for the device to have a uniform temperature and stable operation;

[0067] (3) Take 350 microliters of the solid-liquid mixture obtained in step (1) and put it into the injector, and use the injector to inject the solid-liquid mixture into a device with stable operation. The solid-liquid mixture spreads rapidly at the bottom of the spin coating pool and cools Freeze, wait for 1 minute to obtain a crystalline film;

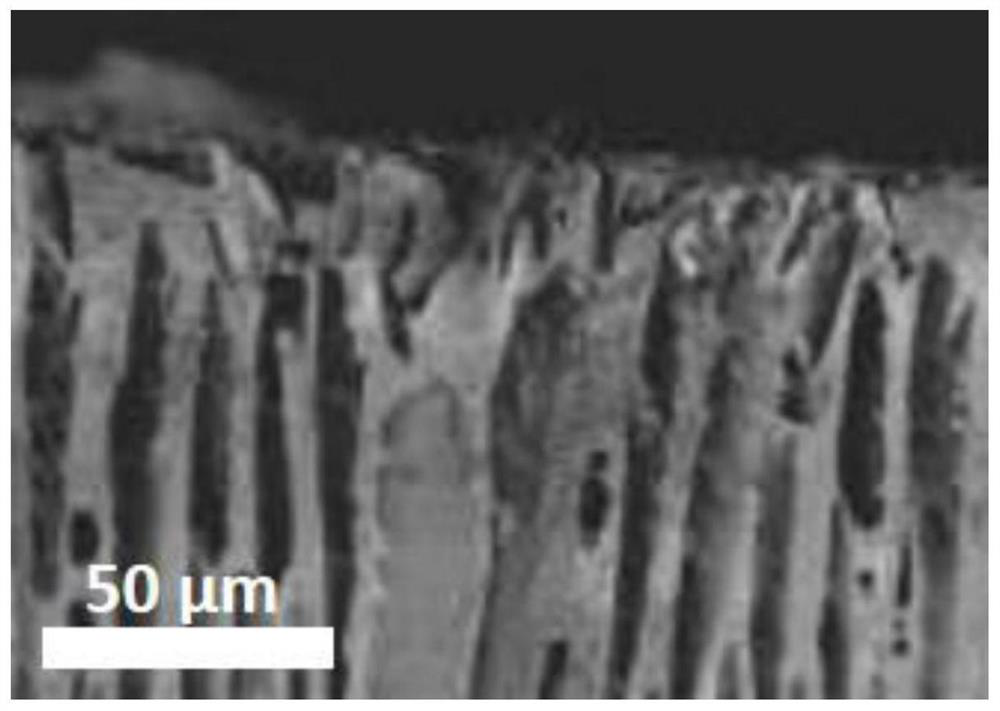

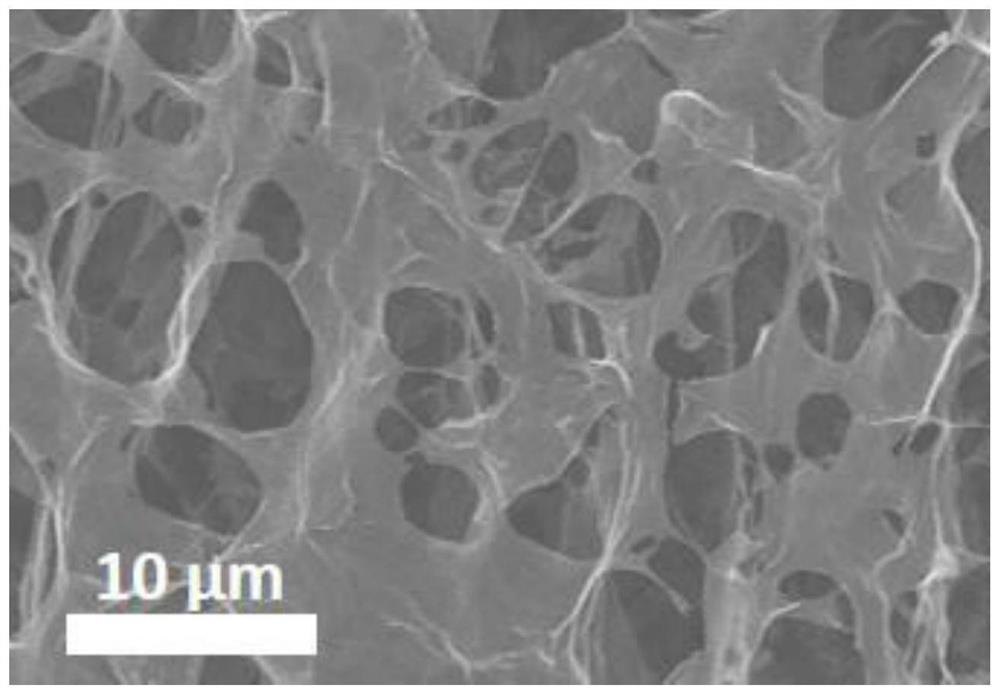

[0068] (4) Put the crystalline film obtained in step (3) into a freeze dryer at -60°C for 48 hours and freeze-dry for 48 hours. After sublimation of the ...

Embodiment 2

[0070] (1) Get the suspension of 5ml 0.5mg / ml graphene oxide in water and the potassium chloroplatinate of 0.5ml 0.01mol / L in ice-water bath and stir reaction 30min, obtain the graphene oxide solid-liquid mixture that is loaded with platinum, Graphene oxide solid powder loaded with platinum was obtained after freeze-drying, that is, Pt / GO;

[0071] (2) Use the platinum-loaded graphene oxide obtained in step (1) and water to prepare 8 mg / ml platinum-loaded graphene oxide suspension, and mix it with 1wt% polytetrafluoroethylene solution at a volume ratio of 1:1 , sonicate for 10 minutes to obtain a solid-liquid mixture;

[0072] (3) use figure 1 The device uses ethanol as a refrigerant, turns on the freezing device to cool the ethanol to -60°C, turns on the rotating device and sets the rotation speed to 2000r / min, and waits for 15 minutes for the device to have a uniform temperature and stable operation;

[0073] (4) Take 350 microliters of the solid-liquid mixture obtained in...

Embodiment 3

[0076] (1) Get 0.873g nickel nitrate hexahydrate and 0.404g ferric nitrate nonahydrate to be dissolved in 40ml water to make saline solution, 0.48g sodium hydroxide and 0.088g sodium hypophosphite to be dissolved in 40ml water to make alkali solution, salt solution and Alkaline solution is double-dropped in 80ml 0.94mg / ml graphene suspension under the condition of nitrogen gas, the pH value of the solution is maintained at about 8.5, stirred for 12 hours, centrifuged and washed, and the nickel-iron composite hydroxide grown on the graphene is obtained colloid;

[0077] (2) The dispersion liquid of the nickel-iron composite hydroxide colloid grown on the graphene obtained in step (1) of about 8mg / ml is mixed with the 1wt% polytetrafluoroethylene solution with a volume ratio of 1:1, and ultrasonic 10 minutes to obtain a solid-liquid mixture;

[0078] (3) use figure 1 The device uses ethanol as a refrigerant, turns on the freezing device to cool the ethanol to -60°C, turns on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com