Preparation method of lithium vanadium phosphate of lithium ion batteries cathode materials

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as complex processes and insufficient parameter values, and achieve the effects of wide sources, stable discharge voltage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of lithium vanadium phosphate lithium ion battery positive electrode material, weigh V respectively by mass ratio 19.8:12.0:37.5:30.7 2 o 5 , Li 2 CO 3 , NH 4 h 2 PO 4 and citric acid. will V 2 o 5 , Li 2 CO 3 , NH 4 h 2 PO 4 Mix the dry powder evenly, add deionized water accounting for 25% of the mass fraction of the above three raw materials and stir for 1 hour; add distilled water to make citric acid into a solution with a mass concentration of 35%, add it to the above materials, and stir at a constant temperature of 80°C until solidified. Dry the above mixture at 120°C and ball mill at 250r / min; then place the mixture under N 2 In the atmosphere, raise the temperature to 800°C at 3°C / min, keep it warm for 12 hours, then cool down to room temperature with the furnace, take it out, pulverize and sieve to obtain 1# sample.

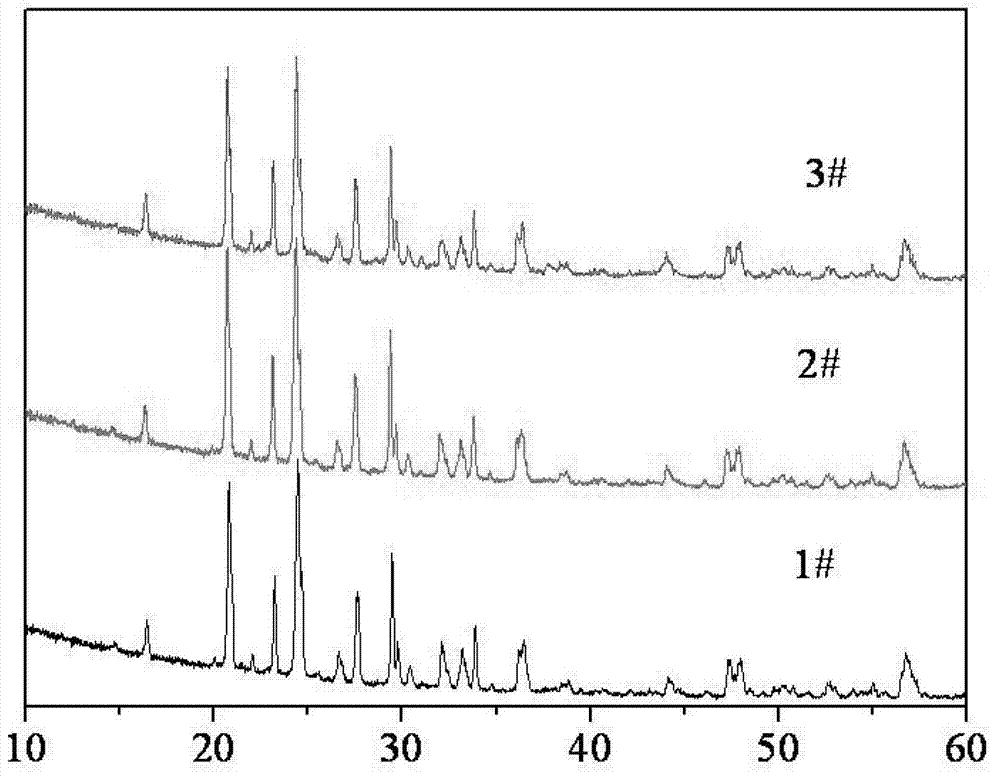

[0030] From figure 1 The X-ray diffraction spectrum of the 1# sample prepared in Example 1 shows that it is ...

Embodiment 2

[0037] The preparation method of lithium vanadium phosphate lithium ion battery positive electrode material, weigh V respectively by mass ratio 19.8:12.0:37.5:30.7 2 o 5 , Li 2 CO 3 , NH 4 h 2 PO 4 and citric acid. will V 2 o 5 , Li 2 CO3 , NH 4 h 2 PO 4 Mix the dry powder evenly, add deionized water accounting for 25% of the mass fraction of the above three raw materials and stir for 1 hour; add distilled water to make citric acid into a solution with a mass concentration of 35%, add it to the above materials, and stir at a constant temperature of 80°C until solidified. Dry the above mixture at 120°C and ball mill at 250r / min; then place the mixture under N 2 In the atmosphere, the temperature was raised to 800°C at a rate of 3°C / min, and kept for 8 hours, then cooled to room temperature with the furnace, taken out, crushed and sieved to obtain 2# sample.

[0038] From figure 1 The X-ray diffraction spectrum of the 2# sample prepared in Example 2 shows that it i...

Embodiment 3

[0044] The preparation method of lithium vanadium phosphate lithium ion battery positive electrode material, weigh V respectively by mass ratio 19.8:12.0:37.5:30.7 2 o 5 , Li 2 CO 3 , NH 4 h 2 PO 4 and citric acid. will V 2 o 5 , Li 2 CO 3 , NH 4 h 2 PO 4 Mix the dry powder evenly, add deionized water accounting for 25% of the mass fraction of the above three raw materials and stir for 1 hour; add distilled water to make citric acid into a solution with a mass concentration of 35%, add it to the above materials, and stir at a constant temperature of 80°C until solidified. Dry the above mixture at 120°C and ball mill at 250r / min; then place the mixture under N 2 In the atmosphere, raise the temperature to 800°C at 3°C / min, keep it warm for 4 hours, then cool to room temperature with the furnace, take it out, pulverize and sieve to obtain 3# sample.

[0045] From figure 1 It can be seen from the X-ray diffraction spectrum of the 3# sample prepared in Example 3, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com