Chemical nickel plating solution treatment device and treatment method thereof

A technology of electroless nickel plating solution and treatment device, which is applied in chemical instruments and methods, water treatment of special compounds, filtration treatment, etc., can solve problems such as difficult treatment of electroless nickel plating waste solution, achieve better precipitation effect, and reduce ammonia nitrogen content , the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

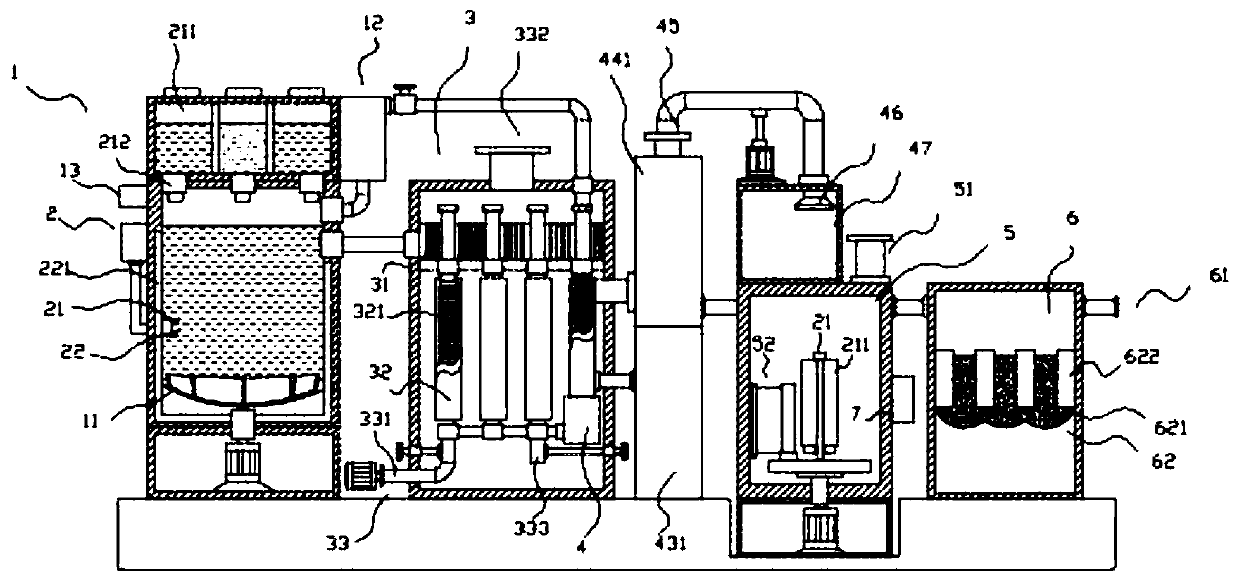

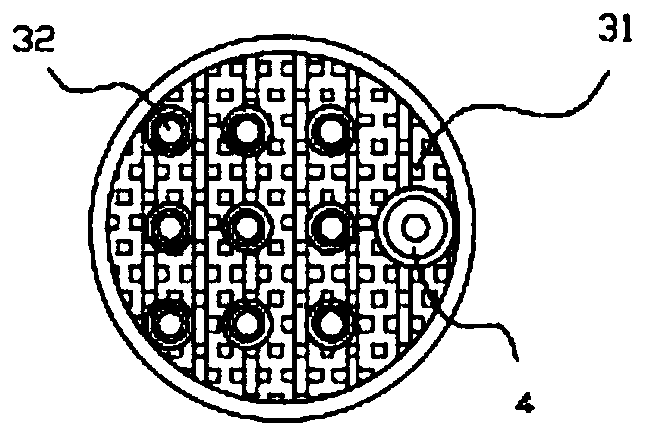

[0035] Such as figure 1 Shown, a kind of electroless nickel plating solution treatment device mainly comprises: self-catalysis reaction tank 1, filter tank 3, concentration structure 4, precipitation crystallization tank 5 and chemical precipitation tank 6, described self-catalysis reaction tank 1, filter tank 3 , the concentration structure 4, the precipitation crystallization tank 5 and the chemical precipitation tank 6 are connected in sequence through the connecting pipe;

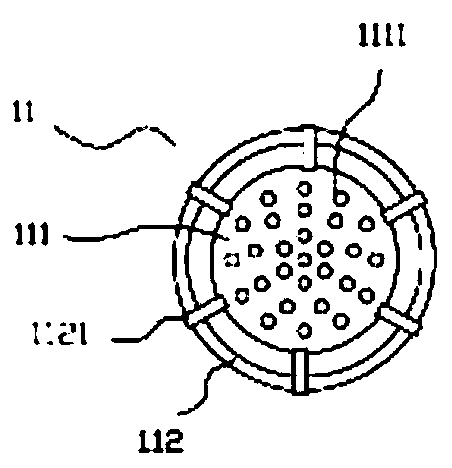

[0036] Described self-catalysis reaction tank 1 comprises: the controller 2 that can automatically adjust temperature and pH value in self-catalysis reaction tank 1, the catalytic mechanism 11 that is used to improve self-catalysis reaction rate and the steam box 12 that is used for reaction vapor collection, so A waste liquid inlet pipe 13 is set up on one side of the catalytic reaction tank 1, and a 51 single-chip microcomputer and a relay purchased from Digi-Key Electronics are arranged inside the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com