Method for treating chemical nickel-plating waste liquid by utilizing autocatalytic reaction

A technology of electroless nickel plating and autocatalysis, applied in chemical instruments and methods, filtration treatment, precipitation treatment, etc., can solve the problems of ineffective removal of nickel metal, complicated process operation, reduction of nickel concentration, etc., so as to reduce production and operation costs. Economic benefits, good removal effect, good metallic luster effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

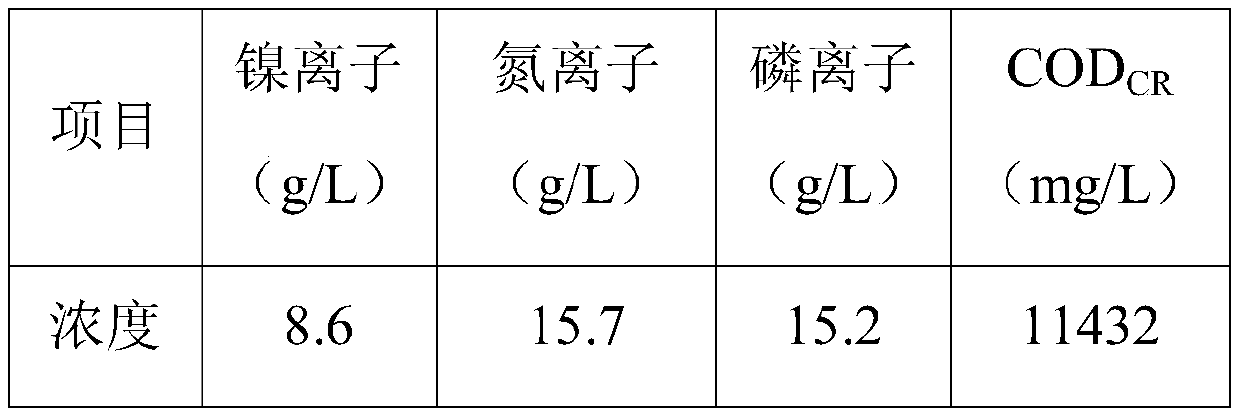

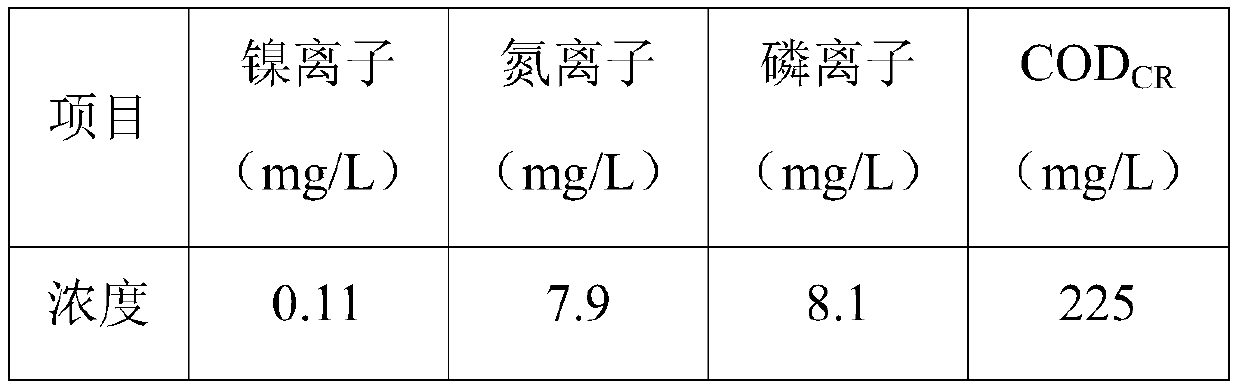

Embodiment 1

[0036] A method utilizing autocatalytic reaction to process electroless nickel plating waste liquid, comprising the following steps:

[0037] (1) Add caustic soda powder to the waste electroless nickel plating liquid, adjust the pH of the waste electroless nickel plating liquid to be treated to be 10, then carry out ultrasonic dispersion for 40min;

[0038] (2) Add treatment preparation to the electroless nickel plating waste liquid to be treated after ultrasonic dispersion, and obtain reaction solution after fully reacting for 40 minutes; The treatment preparation is to include a support body and a reaction layer deposited on the support body, so The particle diameter of the support body is 0.7mm, the reaction layer is nickel chloride, the reaction layer accounts for 1% by mass of the treatment preparation, and the material of the support body is selected from titanium dioxide or corundum; The addition amount of treatment preparation is 10g / L;

[0039] (3) The reaction solut...

Embodiment 2

[0056] A method utilizing autocatalytic reaction to process electroless nickel plating waste liquid, comprising the following steps:

[0057] (1) Add caustic soda powder to the waste electroless nickel plating liquid, adjust the pH of the waste electroless nickel plating liquid to be treated to be 11, then carry out ultrasonic dispersion for 30min;

[0058] (2) Add treatment preparation to the electroless nickel plating waste liquid to be treated after ultrasonic dispersion, obtain reaction solution after fully reacting for 45min; Described treatment preparation is to comprise support body and be deposited on the reaction layer on described support body, so The particle diameter of the support body is 0.6mm, the reaction layer is nickel chloride, the reaction layer accounts for 2% by mass of the treatment preparation, and the material of the support body is selected from titanium dioxide or corundum; The addition amount of treatment preparation is 5g / L;

[0059] (3) The react...

Embodiment 3

[0076] A method utilizing autocatalytic reaction to process electroless nickel plating waste liquid, comprising the following steps:

[0077] (1) Add caustic soda powder to the electroless nickel plating waste liquid, adjust the pH of the chemical nickel plating waste liquid to be treated to be 10-11, and then carry out ultrasonic dispersion for 30min-40min;

[0078] (2) Add a treatment preparation to the electroless nickel plating waste liquid to be treated after ultrasonic dispersion, and obtain a reaction solution after fully reacting for 40min-45min; the treatment preparation includes a support body and a reaction layer deposited on the support body , the particle size of the supporting body is 0.6mm-0.7mm, the reaction layer is nickel chloride, the mass percentage of the reaction layer in the treatment preparation is 1%-2%, and the material of the supporting body is selected From titanium dioxide or corundum; the addition amount of the treatment preparation is 5g / L-10g / L;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com