Preparation method and processing equipment of rosin resin

A technology of rosin resin and processing equipment, applied in the field of rosin processing, which can solve the problems of unfavorable rosin resin widely used, deep color, poor thermal stability, etc., and achieve the effect of reducing heat emission, improving thermal stability, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

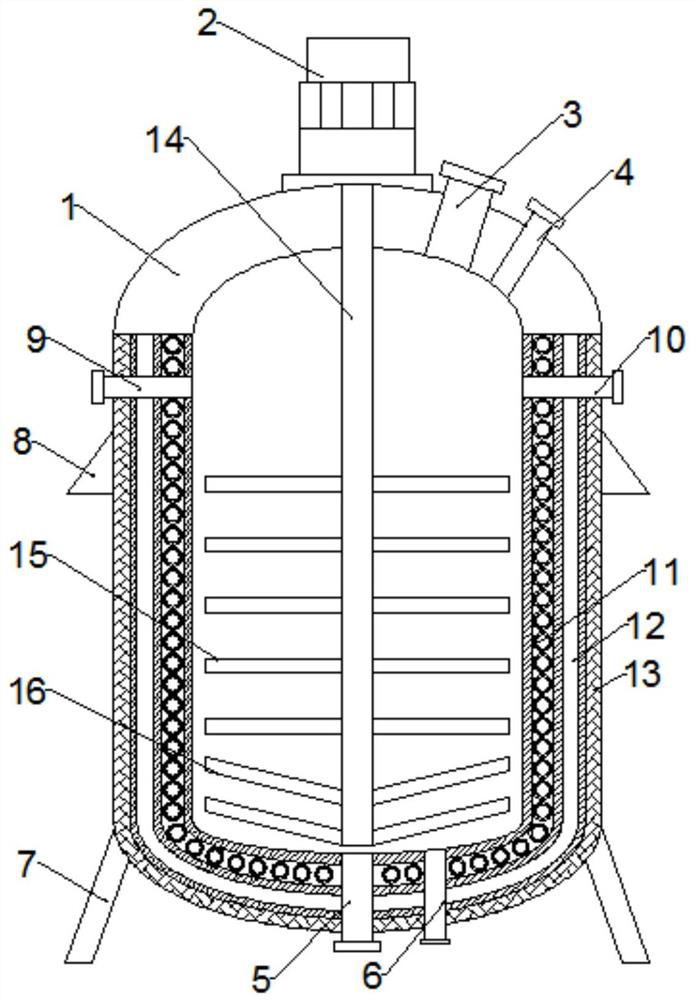

[0024] A kind of processing equipment used in the preparation method of rosin resin, comprises reactor shell 1, agitator 2, feed pipe 3 and discharge pipe 5, and described agitator 2 is above described reactor shell 1 , and the stirring shaft 14 of the agitator 2 is inserted in the reactor shell 1, and the left and right sides of the stirring shaft 14 in the reactor shell 1 are provided with a number of stirring blades 15, the The left and right sides of the bottom end of the stirring shaft 14 are respectively fixed with two stirring blades 16, the feed pipe 3 is positioned on the upper side of the reactor shell 1, and the upper side of the reactor shell 1 is also provided with Auxiliary material pipe one 4, the middle part of the bottom end of the reactor shell 1 is provided with a discharge pipe 5, and the bottom end of the reactor shell 1 is also provided with an auxiliary material pipe two 6, the bottom end of the reactor shell 1 is A support rod 7 is provided, a pressure ...

Embodiment 2

[0027] A preparation method for rosin resin, specifically comprising the following steps:

[0028] 1) Modified catalyst carrier: first make the concentration of 2mol / L NH 4 HCO 3 solution and 2mol / L Al(OH) 3 Solution reaction, adjustment makes the pH value of reaction be between 9, reacts and filters and obtains precipitate, and the precipitate obtained is cleaned, makes the precipitate after cleaning and mass concentration be 8% TiO 2 Reaction, adding ethanol and sodium pyrophosphate at the same time, under the condition of heating in a water bath, the reaction temperature is 75°C, after the reaction, perform suction filtration, washing, impregnation, drying, and calcination to obtain modified nano-alumina;

[0029] 2) prepare catalyst: first make 30 parts of nano silicon dioxide and 0.2 part of emulsifier add 60 parts of deionized water, described emulsifier comprises polyoxyethylene 20 sorbitan monooleate and glyceryl monostearate, and The mass ratio between the polyoxye...

Embodiment 3

[0032] A preparation method for rosin resin, specifically comprising the following steps:

[0033] 1) Modified catalyst carrier: first make the concentration of 2mol / L NH 4 HCO 3 solution and 2mol / L Al(OH) 3 Solution reaction, adjustment makes the pH value of reaction between 10, reacts and filters and obtains precipitate, the precipitate obtained is cleaned, makes the precipitate after cleaning and mass concentration be 8% TiO 2 Reaction, adding ethanol and sodium pyrophosphate at the same time, under the condition of heating in a water bath, the reaction temperature is 85°C, after the reaction, perform suction filtration, washing, impregnation, drying, and calcination to obtain modified nano-alumina;

[0034] 2) prepare catalyst: first make 50 parts of nano silicon dioxide and 0.4 part of emulsifier add 80 parts of deionized water, described emulsifier comprises polyoxyethylene 20 sorbitan monooleate and glyceryl monostearate, and The mass ratio between the polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com