A kind of solid base forming catalyst for biodiesel

A technology of biodiesel and solid base, applied in physical/chemical process catalysts, biofuels, fatty acid esterification, etc., can solve the problems of high energy consumption and high equipment requirements, and achieve high-efficiency catalytic reactions, good catalytic performance, and low The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

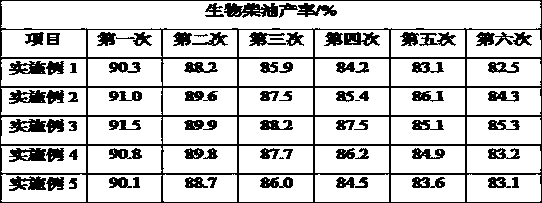

Examples

Embodiment 1

[0028] A kind of solid base forming catalyst for biodiesel is prepared by the following steps:

[0029] 1) Grind paper-making sludge ash, pass through a 50-mesh sieve, and activate at 550°C for 0.5 hours to obtain activated paper-making sludge ash;

[0030] The papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 600°C;

[0031] 2) Add the activated papermaking sludge ash to the sodium metasilicate solution with a concentration of 20%, stir evenly, soak for 8 hours, squeeze to remove water, and obtain the initial material;

[0032] The mass ratio of the activated papermaking sludge ash and sodium metasilicate is 1:1;

[0033] 3) Add the initial material to the sodium metasilicate solution with a concentration of 30%, stir evenly, and soak for 10 hours to obtain the impregnating material;

[0034] The mass ratio of described starting material and sodium metasilicate is 2.5:1;

[0035] 4) Add clay to the impregnating material, mix evenly, extrud...

Embodiment 2

[0038] A kind of solid base forming catalyst for biodiesel is prepared by the following steps:

[0039] 1) Grind paper-making sludge ash, pass through a 50-mesh sieve, and activate at 520°C for 1 hour to obtain activated paper-making sludge ash;

[0040] The papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 650°C;

[0041] 2) Add the activated papermaking sludge ash to the sodium metasilicate solution with a concentration of 23%, stir evenly, soak for 7 hours, squeeze to remove water, and obtain the primary material;

[0042] The mass ratio of the activated papermaking sludge ash to sodium metasilicate is 1.5:1;

[0043] 3) Add the initial material to the sodium metasilicate solution with a concentration of 33%, stir evenly, and soak for 9 hours to obtain the impregnating material;

[0044] The mass ratio of described starting material and sodium metasilicate is 2:1;

[0045] 4) Add clay to the impregnating material, mix evenly, extrude, dr...

Embodiment 3

[0048] A kind of solid base forming catalyst for biodiesel is prepared by the following steps:

[0049] 1) Grind paper-making sludge ash, pass through a 50-mesh sieve, and activate at 500°C for 1 hour to obtain activated paper-making sludge ash;

[0050] The papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 700°C;

[0051] 2) Add the activated papermaking sludge ash to the sodium metasilicate solution with a concentration of 25%, stir evenly, soak for 6 hours, squeeze to remove water, and obtain the primary material;

[0052] The mass ratio of the activated papermaking sludge ash to sodium metasilicate is 1.5:1;

[0053] 3) Add the initial material to the sodium metasilicate solution with a concentration of 35%, stir evenly, and soak for 8 hours to obtain the impregnating material;

[0054] The mass ratio of described starting material and sodium metasilicate is 2:1;

[0055] 4) Add clay to the impregnating material, mix evenly, extrude, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com