Methods and systems for treating alkaline chemical nickel plating wastewater

A technology for electroless nickel plating and wastewater, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

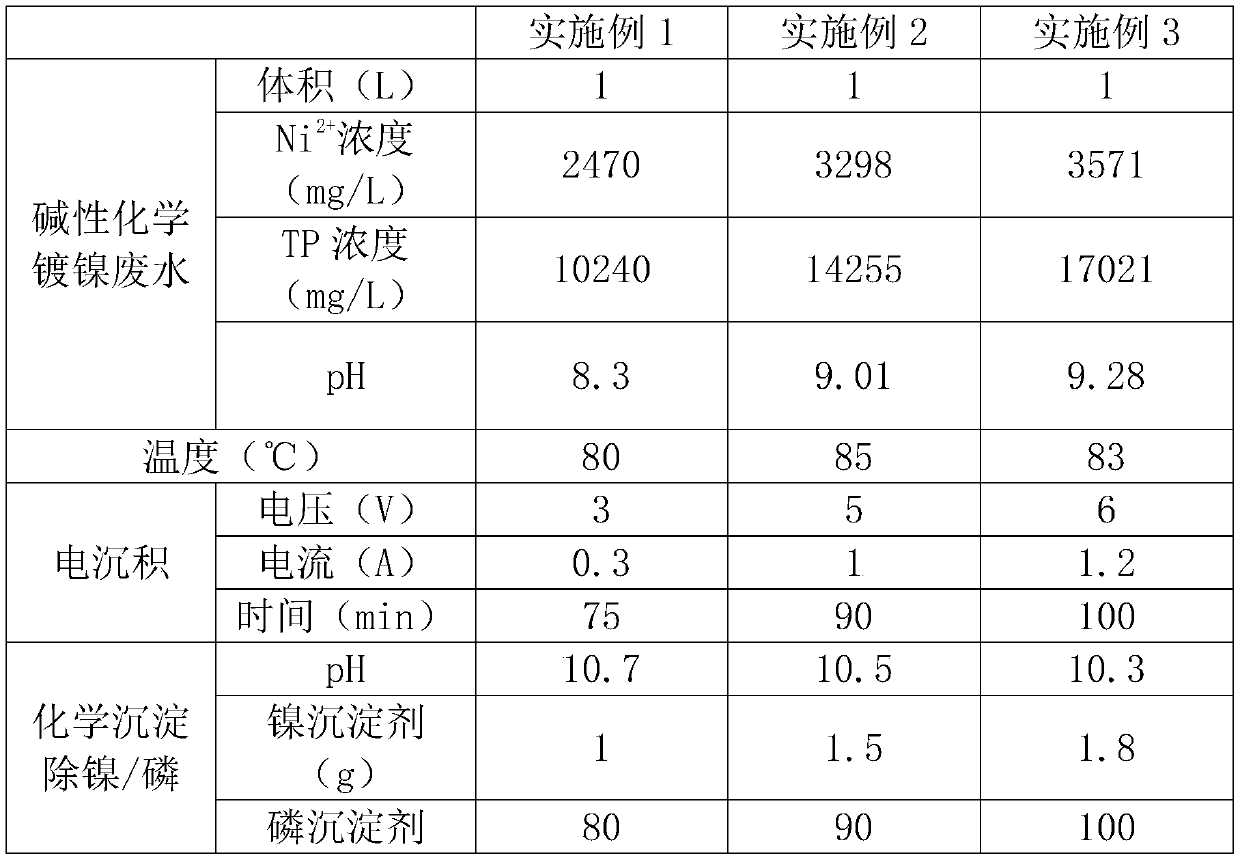

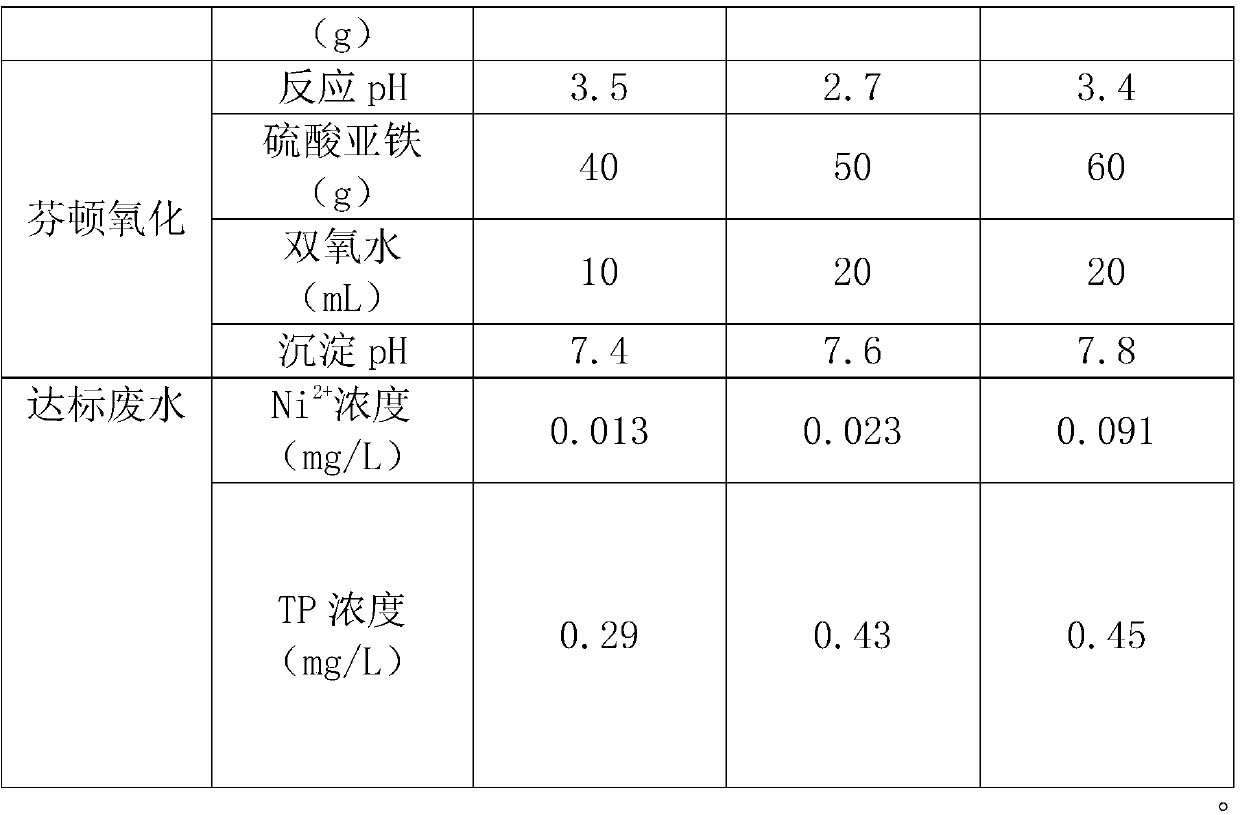

Examples

Embodiment Construction

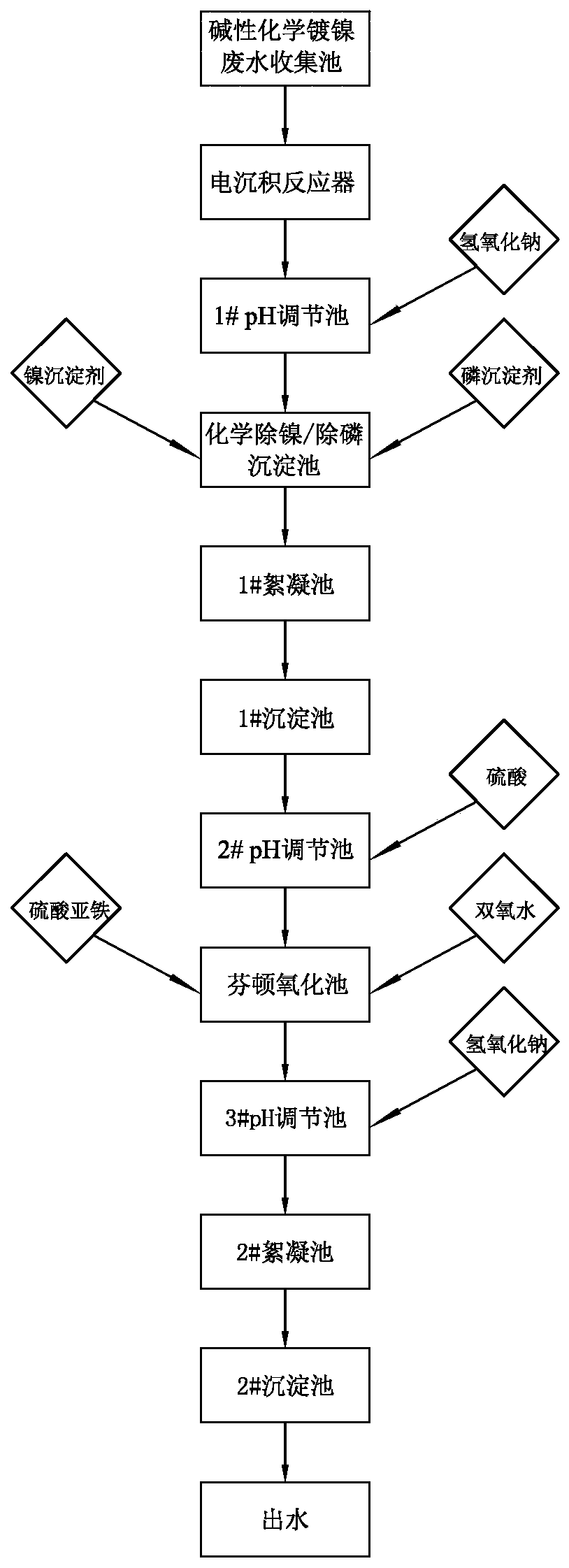

[0049] Such as figure 1 Shown, the method and system for processing alkaline electroless nickel plating waste water of the present invention are made of following equipment, are respectively alkaline chemical nickel collection tank, electrodeposition reactor, 1#pH adjustment tank, chemical precipitation to remove nickel / phosphorus Reactor, 1# flocculation tank, 1# sedimentation tank, 2# pH adjustment, Fenton oxidation reactor, 3# pH adjustment tank, 2# flocculation tank and 2# sedimentation tank, the functions of each equipment are as follows:

[0050] 1. Alkaline chemical nickel collection pool: collect nickel content in 50-5000mg / L; phosphorus content in 200-30000mg / L; COD in 400-50000mg / L alkaline chemical nickel plating wastewater stock solution, the components in the waste water stock solution Mainly sodium hypophosphite, sodium citrate, ammonium chloride, ammonium hydroxide and nickel sulfate. Its pH value is 8.0-10.

[0051] 2. Electrodeposition: In the stock solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com