Preparation method of titanium alloy plates

A technology for titanium alloys and plates is applied in the field of preparation of titanium alloy plates, which can solve the problems of unsatisfactory comprehensive mechanical ability of titanium-based alloys, complicated processing technology, etc., and achieves advantages of popularization and application, strong process stability, and simple and easy method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

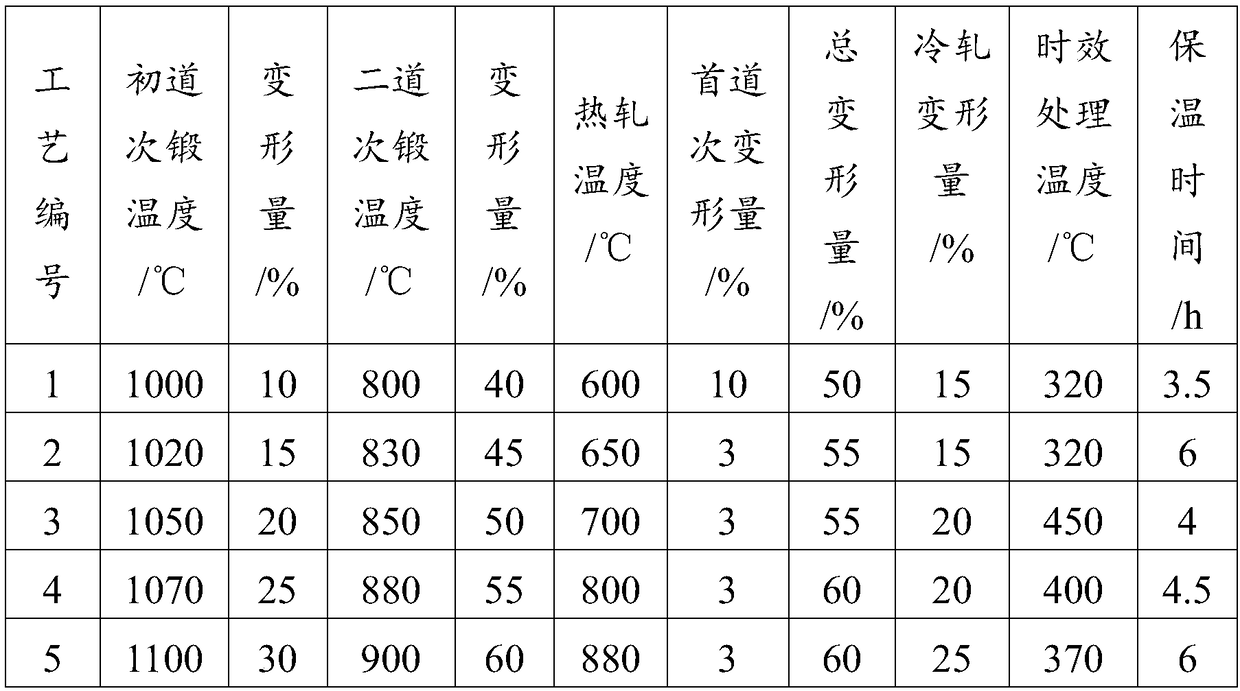

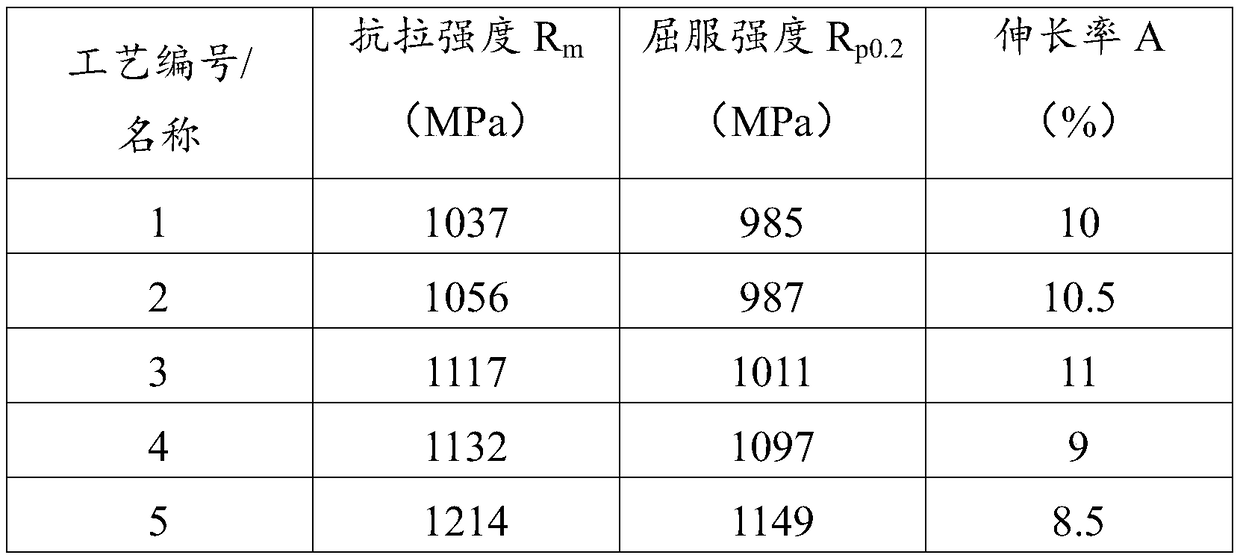

[0026] This embodiment provides a method for preparing a titanium alloy plate, which includes the following steps:

[0027] S1. Initial forging of ingot, the initial forging temperature of the two forging passes is 1000°C-1100°C, the deformation in the first pass is 10-60%; the forging temperature in the second pass is 800-900°C, and the total deformation is greater than 60%; Yes, the alloy ingot is forged into a forging billet after peeling off the surface and cutting off the riser, including; open billet forging and two-fire forging, both of which can be forged with two piers and two draws.

[0028] S2. The forging blank is subjected to stress relief and α-phase quenching and tempering heat treatment, and then cooled to room temperature after heat preservation;

[0029] Specifically, the heat treatment temperature is controlled at 400° C. to 650° C., kept for 1 to 2 hours, and cooled to room temperature after the heat preservation.

[0030] Preferably, during the annealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com