Machining technology for high-precision outer conical surface thin wall sleeve

A processing technology and technology of the outer cone surface, which is applied in the field of high-precision outer cone surface thin-walled sleeve processing technology, can solve the problems of high precision requirements and easy deformation, and achieve the goals of avoiding force deformation, reducing deformation, and excellent manufacturing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

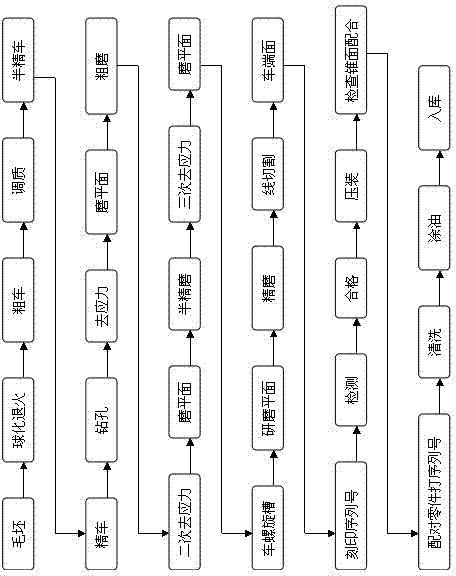

[0025] A high-precision outer tapered thin-wall sleeve processing technology, including the following process: blank→spheroidizing annealing→rough turning→quenching and tempering→semi-finishing turning→finishing turning→drilling→stress relief→surface grinding→rough grinding→two Secondary stress relief→grinding surface→turning spiral groove→grinding surface→fine grinding→wire cutting→turning end face→engraving serial number→testing→qualified product→press fitting→checking taper fit→printing serial number of paired parts→cleaning→oiling → Storage. In this plan, through two grindings and corresponding stress relief heat treatment, the coarse grinding amount is 0.5~0.6mm, and the fine grinding amount is about 0.2~0.3mm. can be produced as figure 2 The high-precision outer tapered thin-walled sleeve that meets the technical requirements can make the roundness of the inner hole reach 0.012, and the coaxiality between the outer tapered surface and the inner hole reach 0.02. But in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com