Induction coil and equipment used for eliminating residual stress of engine valve, and method

A technology of engine valves and induction coils, which is applied in the field of induction coils to eliminate the residual stress of engine valves, and can solve problems such as difficulty in accurately controlling the tempering temperature, uneven temperature of the bottom surface of the valve head, and inability to measure the temperature of the bottom surface of the valve, etc., to achieve The effect of eliminating valve residual stress, eliminating residual stress, and saving manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

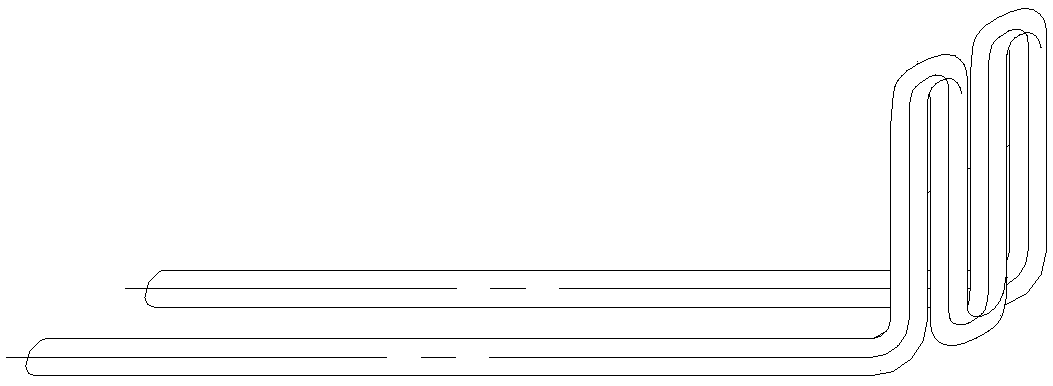

[0028] This embodiment provides an induction coil for eliminating the residual stress of the engine valve, and the induction coil is V-shaped, U-shaped or wave-shaped. It is preferably W-shaped, such as figure 1 shown.

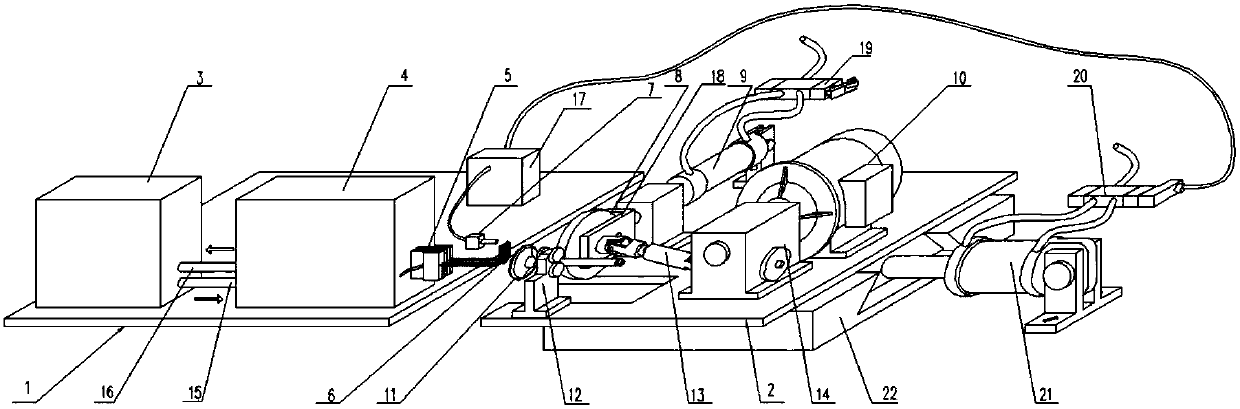

[0029] Such as figure 2 As shown, the present embodiment also provides a device using the above-mentioned induction coil, including a frame, a workbench, a heating device, a fixture and a control device, the workbench includes a fixed workbench 1 and a movable workbench 2, and the fixed workbench The table 1 is fixedly installed on the frame, and the movable workbench 2 is installed on the frame through the feeding device. The heating device is installed on the fixed workbench 1 and includes an induction heating power supply 4 and an induction coil 6. The induction heating device The coil 6 is installed on the output end of the induction heating power supply 4 and is located in front of the clamp fixing tool; the clamp is used to clamp the engine valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com