Automatic distressing device for amorphous alloy iron core

An amorphous alloy and stress-relief technology, which is applied in the field of automatic stress-relief devices for amorphous alloy iron cores, can solve the problems of iron core stress-relief and unsuitable modes, etc., achieve stress elimination, increase production efficiency, reduce work intensity and The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

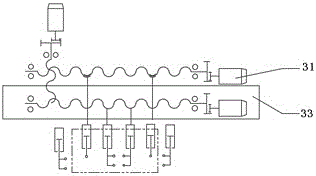

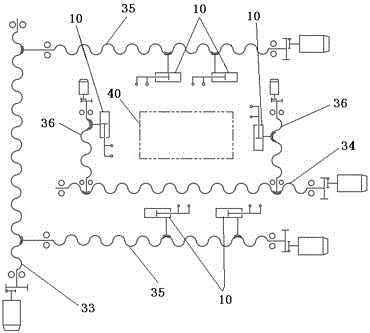

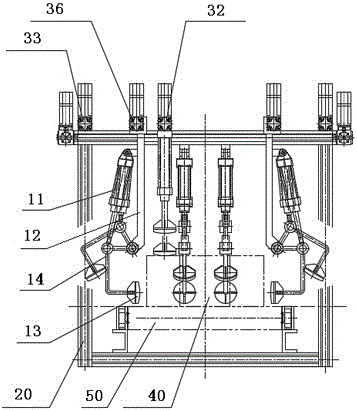

[0023] like Figure 1-4 as shown,

[0024] Stress relief mechanism 10: used to hammer the workpiece to achieve the effect of stress relief;

[0025] Gantry frame 20: supporting screw drive mechanism;

[0026] Lead screw transmission mechanism 30: drives the stress relief mechanism to complete positioning and movement in three directions of Cartesian coordinates;

[0027] Stress relief mechanism 10 comprises cylinder 11, stress relief mechanism base 12, rubber hammer 13, connecting rod 14, cylinder 11 afterbody is hinged with stress relief mechanism base 12, cylinder 11 head is hinged with connecting rod 14 one end, and connecting rod 14 other end is connected with The rubber head 13 is connected by bolts, and the middle part of the connecting rod 14 is hinged to the base 12 of the stress relief mechanism; during the movement, the cylinder 11 telescopically pushes the connecting rod 14 to rotate around the middle hinge point, and the rubber hammer 13 performs hammering treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com