Unconfined compressive strength part and demolding and strength measuring integrated testing machine

A technology of compressive strength and testing machine, which is applied in the direction of strength characteristics, using stable tension/pressure testing material strength, measuring devices, etc., can solve problems such as ineffective control, impact on construction period, single function, etc., to reduce labor intensity , The performance of the equipment is stable, and the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

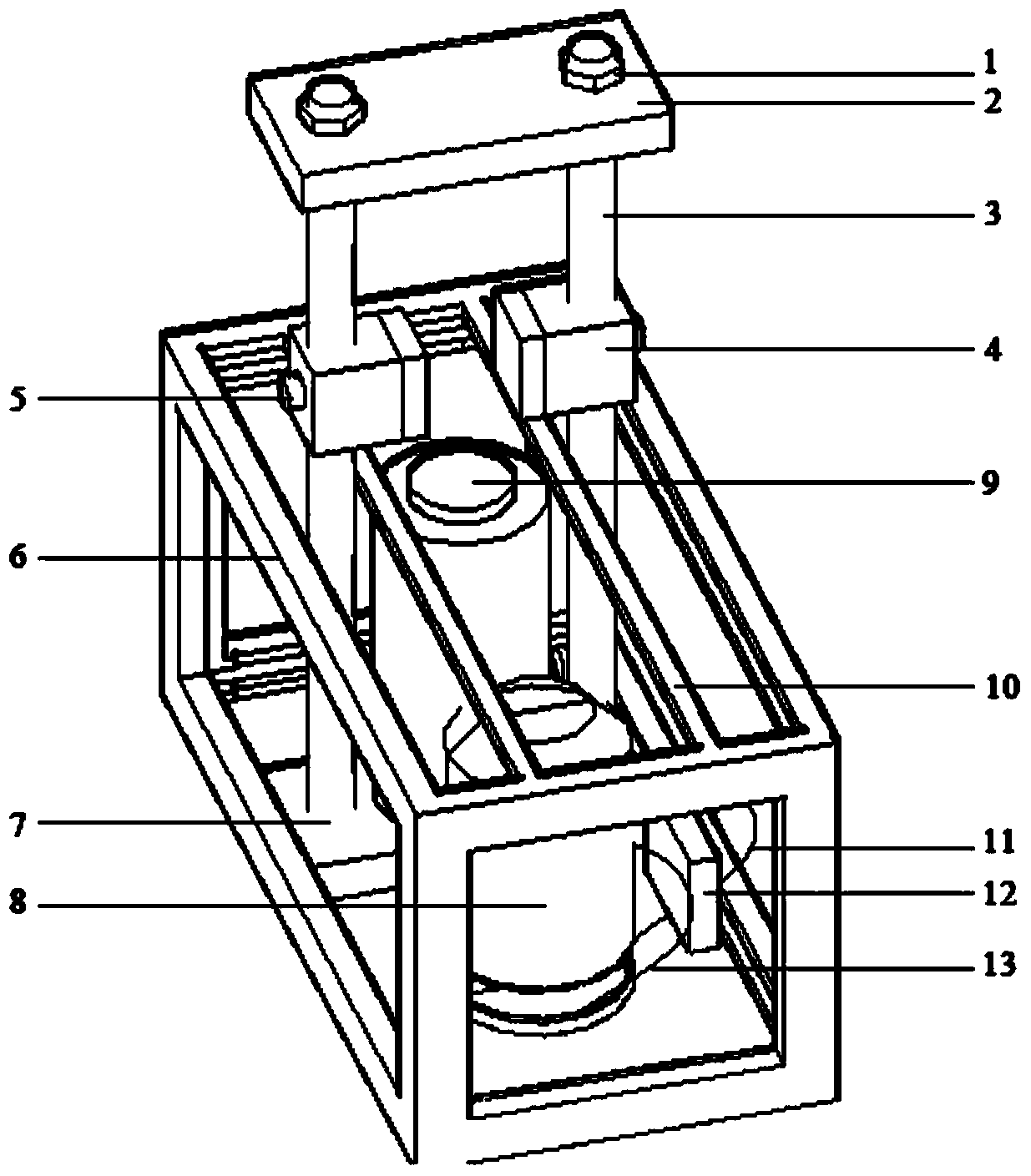

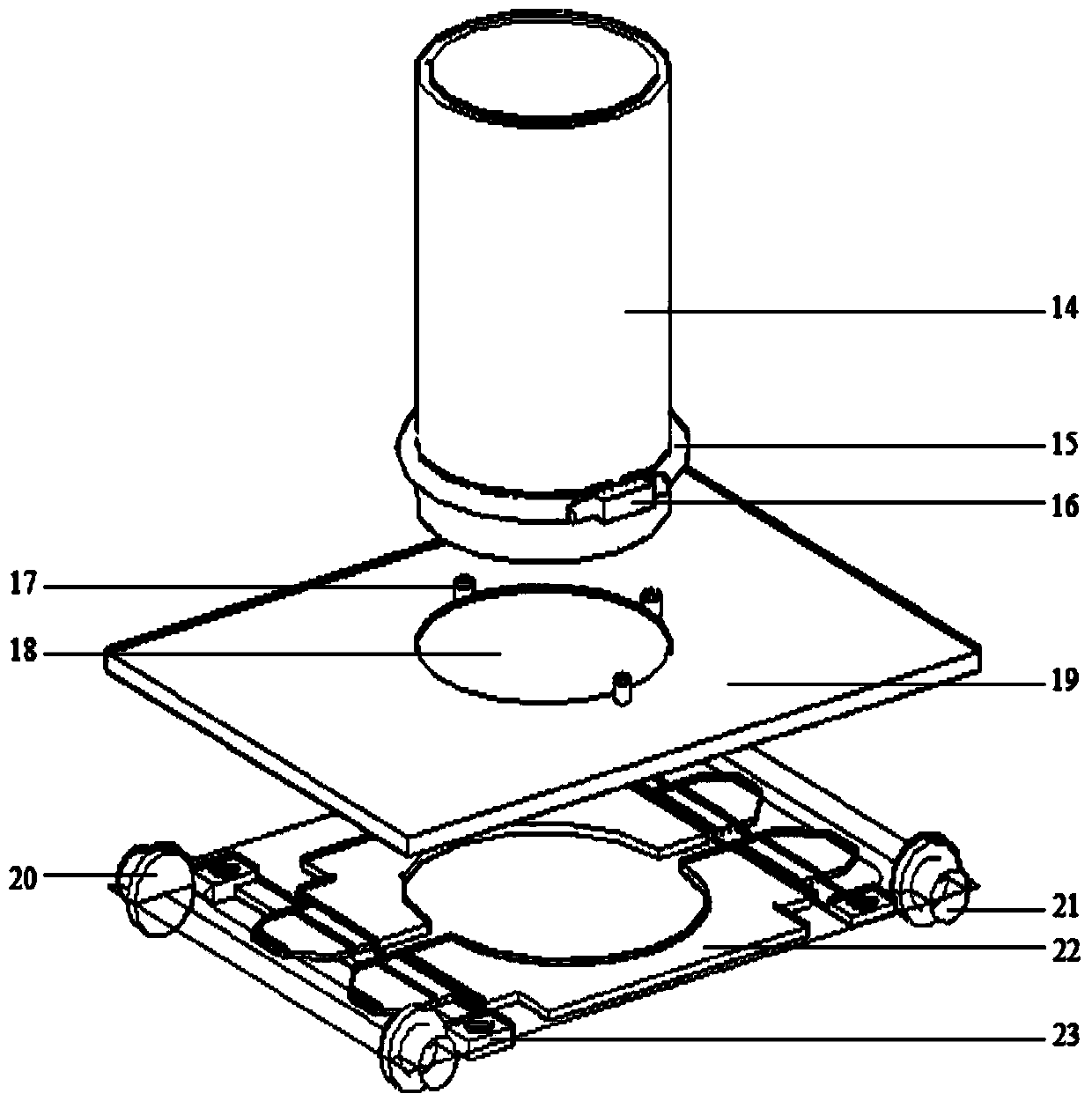

[0017] Such as figure 1 and figure 2 As shown, an integrated testing machine for unconfined compressive strength parts, demoulding and strength measurement is composed of a fixed nut 1, an upper bearing plate 2, a column 3, a clip 4, a jacking screw 5, a frame 6, a lower bearing Plate 7, motor 8, jack 9, track 10, data line 11, pressure sensor 12, hydraulic pipe 13, test mold 14, ring stirrup 15, adjusting screw 16, car panel fixing buckle 17, circular plate with ring groove 18 , Sliding dolly panel 19, wheel 20, axle shaft 21, clamping plate 22 and clamping plate slideway 23 constitute. The fixing nut 1 is a hexagonal nut with an inner diameter of 50mm, which is located outside the upper bearing plate 2 and the lower bearing plate 7, and is used to fix the positions of the upper bearing plate and the lower bearing plate; the upper bearing plate 2 is 400×240× The 60mm rectangular high-strength pressure-bearing steel plate is provided with two round holes inserted into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com