Method using pilot tunnel to process tilting and dumping hydraulic support

A technology of hydraulic support and guide, applied in underground chambers, earth-moving drilling, wellbore lining, etc., can solve the problems of prone to roof accidents, low safety factor, and many gangue falling from the roof, so as to facilitate production organization and coordination, The effect of high operating safety factor and reducing roof accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

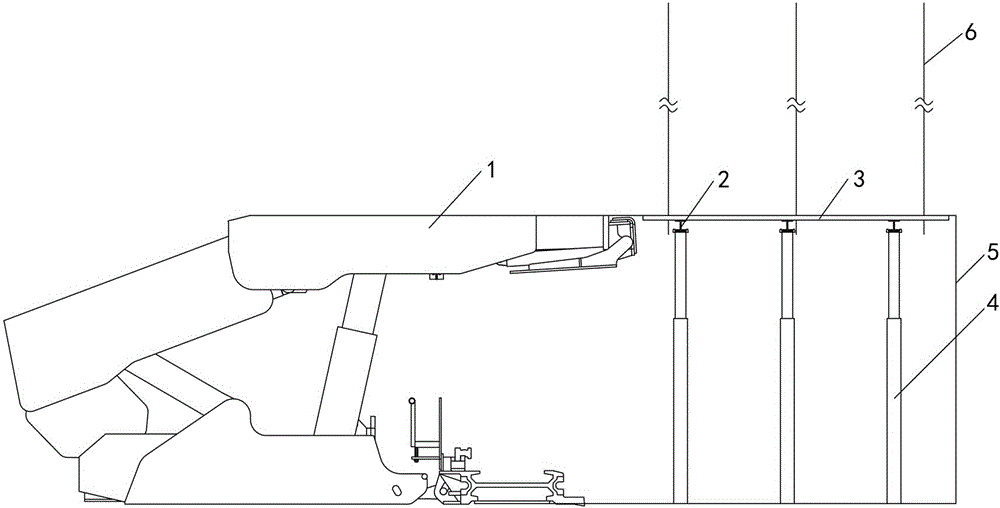

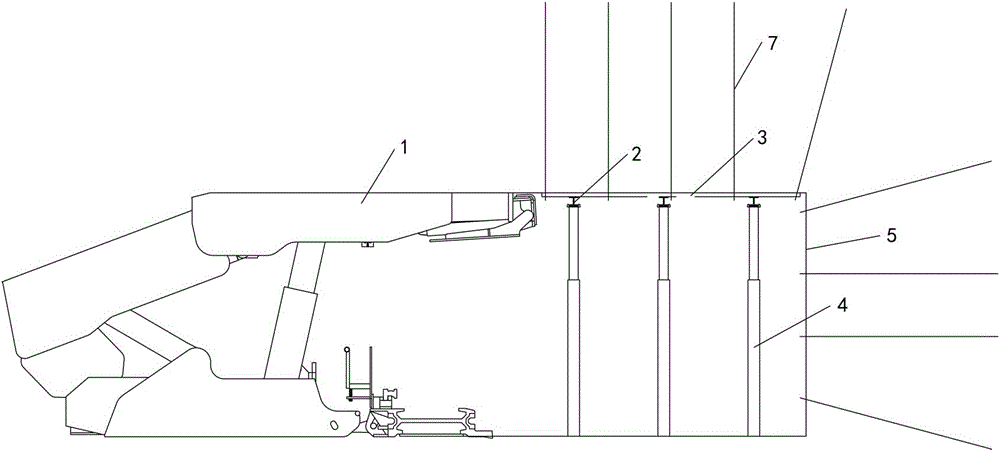

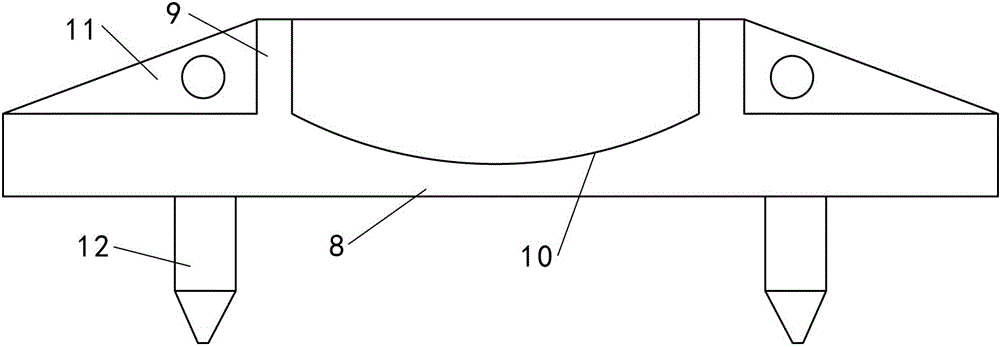

[0028] refer to figure 1 , figure 2 and image 3 According to the specific embodiment, a method for using a guide tunnel to deal with a crooked frame of a hydraulic support includes the following steps:

[0029] 1) Construct the guide tunnel 5 in front of the tilted or toppled hydraulic support 1;

[0030] 2) Use the I-shaped steel shed 2 to reinforce and support the guide tunnel 5;

[0031] 3) Pull the hydraulic support 1 into the position of the guide tunnel 5;

[0032] 4) Righting the hydraulic support 1 in the guide tunnel 5.

[0033] The step 1) is specifically as follows: at the front of the hydraulic support 1, the top plate is relatively complete, and there is no sidewall and leaky roof position, start stripping the sideboard, excavate the guide tunnel 5, and then use the anchor rod 7 and the anchor cable 6 to match the top side of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com