Adjustable clamp for numerically-controlled machine tool

A CNC machine tool, adjustable technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of parts processing that are not suitable for various sizes, waste of space, waste of time, etc., and achieve the effect of preventing damage to the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

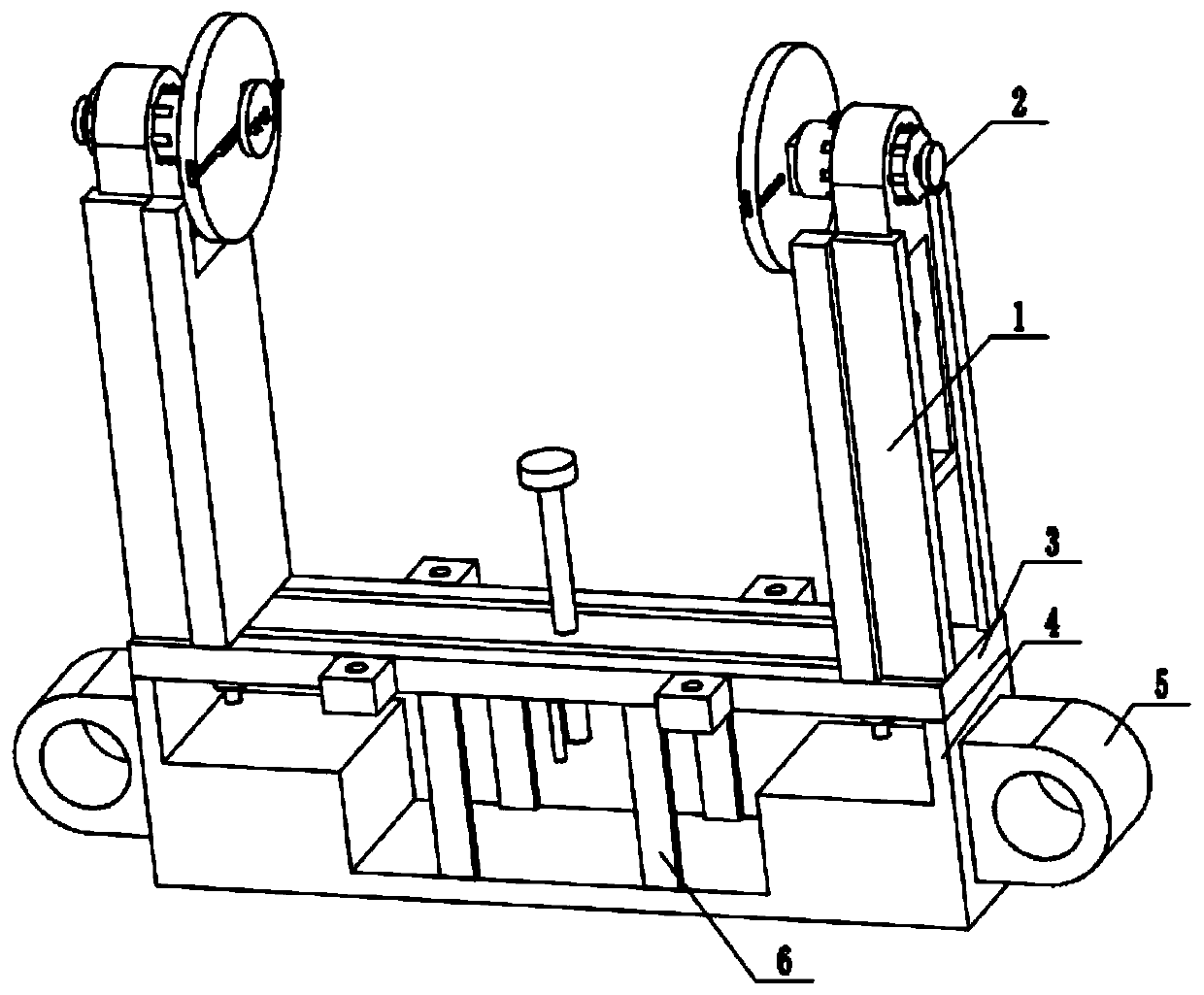

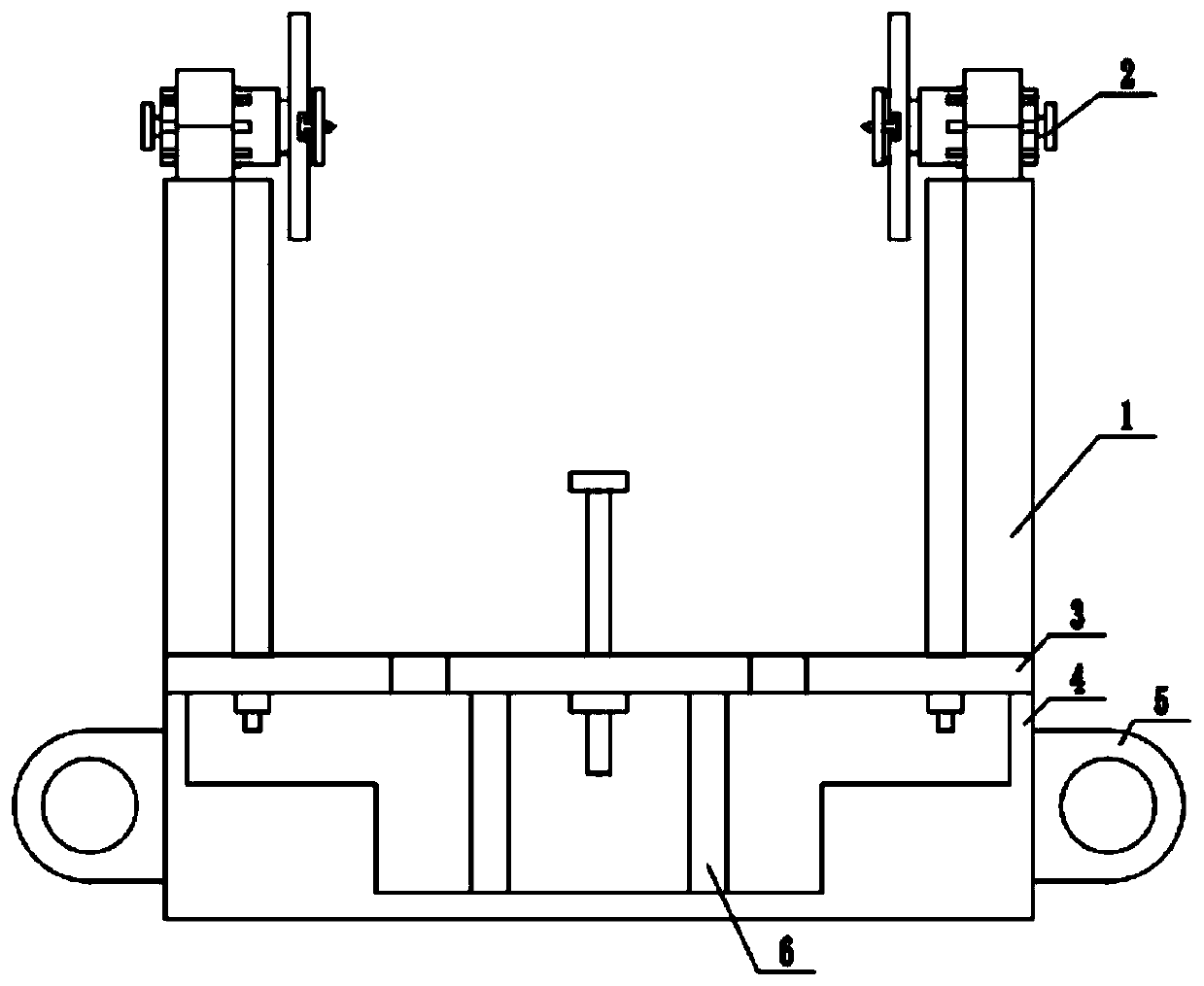

[0037] Combine below figure 1 , 2 In this embodiment, an adjustable clamp for a numerically controlled machine tool includes a lifting adjusting device 1, a workpiece clamping device 2, a workpiece supporting device 3, a fixed base 4, a lifting frame 5, and a support rod 6. The workpiece clamping device 2 It is installed on the lifting adjustment device 1 by keys. There are two lifting adjustment devices 1. The lifting adjustment device 1 is installed on the workpiece support device 3, the workpiece support device 3 is fixedly installed above the fixed base 4, and the lifting frame 5 is fixedly installed On the fixed base 4, the supporting rod 6 is fixedly installed on the workpiece supporting device 3, the other end of the supporting rod 6 is fixedly installed on the fixed base 4, and four supporting rods 6 are provided.

specific Embodiment approach 2

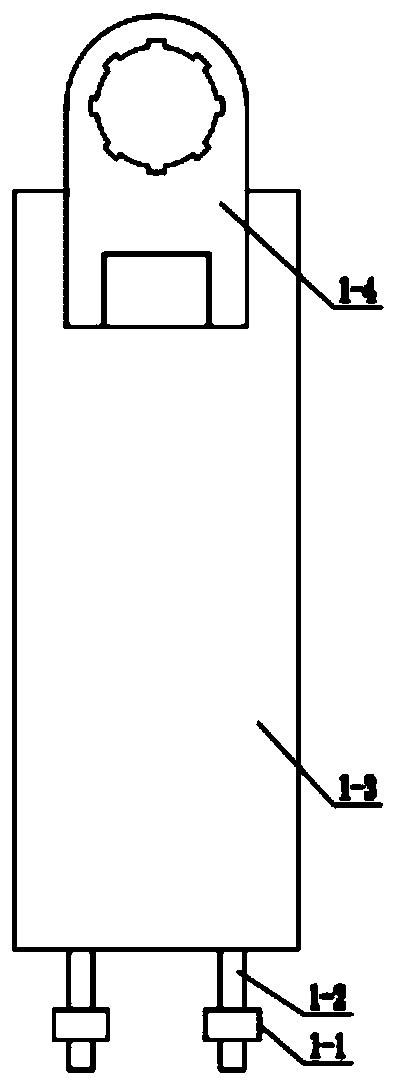

[0039] Combine below image 3 , 4 , 5, 6, 7 illustrate this embodiment, this embodiment will further illustrate the first embodiment, the lifting adjustment device 1 includes a control screw ring 1-1, a control screw 1-2, a support fixing plate 1-3, lifting Frame 1-4, L limit block 1-5, the control screw ring 1-1 is movably installed on the support device 3, the control screw ring 1-1 and the control screw 1-2 are connected by threads, and the control screw 1-2 is fixedly installed On the supporting fixing plate 1-3, the L restriction block 1-5 is fixedly installed on the supporting fixing plate 1-3, and the lifting frame 1-4 is in contact with the L restriction block 1-5 and the supporting fixing plate 1-3, respectively. To adjust the height and limit the movement direction of the lifting frame 1-4;

[0040] The lifting frame 1-4 includes a power motor 1-4-1, a transmission gear A1-4-2, a transmission gear B1-4-3, a gear connecting shaft 1-4-4, and a fixed frame body 1-4-5 , Ke...

specific Embodiment approach 3

[0042] Combine below Figure 8 , 9 , 10, 11, 12, and 13 illustrate this embodiment, and this embodiment further illustrates the first embodiment. The workpiece clamping device 2 includes a rotating handle 2-1, a handle connecting rod 2-2, a clamping mechanism connecting column 2-3. Clamping mechanism 2-4, rotating handle 2-1 is fixedly installed on the handle connecting rod 2-2, the handle connecting rod 2-2 is fixedly installed on the clamping mechanism connecting column 2-3, and the clamping mechanism is connected Multiple key grooves are provided on the column 2-3, and the clamping mechanism 2-4 is fixedly installed on the clamping mechanism connecting column 2-3;

[0043] The clamping mechanism 2-4 includes a fixed center 2-4-1, an eccentric adjusting plate 2-4-2, a fastening screw A2-4-3, an adjusting step bar 2-4-4, and a fixed chassis 2-4 -5. Support wheel 2-4-6, limit center 2-4-7, fastening screw B2-4-8, fixed center 2-4-1 is fixedly installed on eccentric adjustment pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com