Profiling grinding repairing device for end surface of arresting gear of aero-engine

A technology of aero-engines and stoppers, which is applied in the direction of grinding drive devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of uneven grinding quality, affecting production progress, affecting precision requirements, etc., and achieves high grinding efficiency , Reduce labor intensity and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

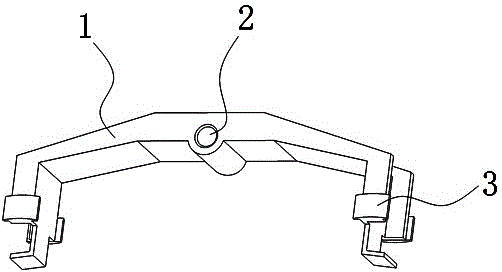

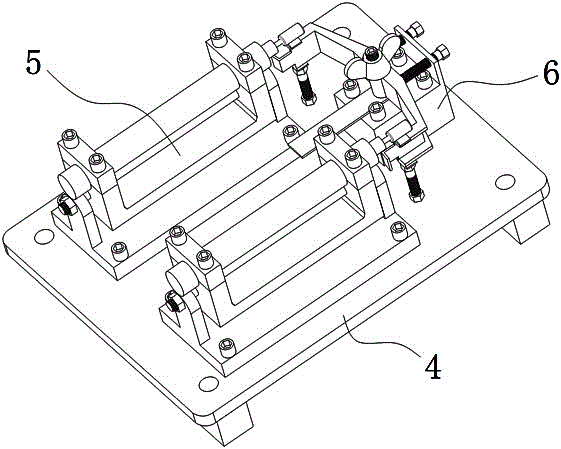

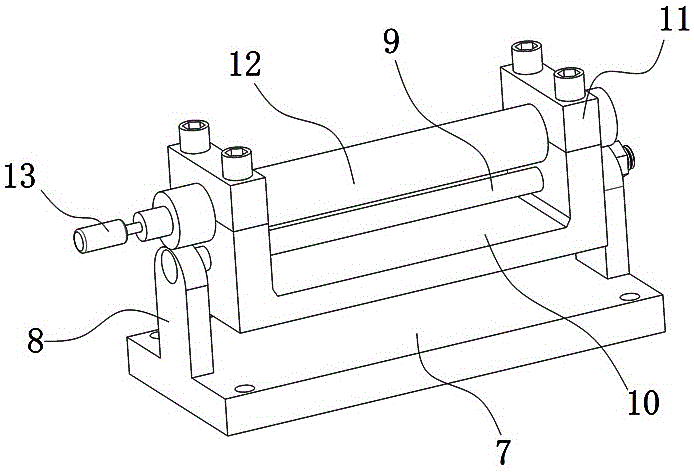

[0025] Please refer to figure 2 , a profiling grinding and repairing device for the end face of an aero-engine limiter, comprising a base 4, a swing mechanism 5, a clamping mechanism 6 and a grinding mechanism, the swing mechanism 5 is fixedly installed on one side above the base 4, and the clamping mechanism 6 is fixedly installed on the other side above the base 4, the grinding mechanism is installed on the swing mechanism 5, the stopper 1 is fixed on the clamping mechanism 6, and the output end of the grinding mechanism grinds the arc of the stopper 1 The end face 3 and the output end of the grinding mechanism can perform reciprocating arc swing relative to the arc end face 3 under the swing action of the swing mechanism 5 .

[0026] Preferably, there are two groups of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com