Cylindrical lithium ion battery

A lithium-ion battery, cylindrical technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of poor sealing, large power failure and pressure relief value, unable to act in time, etc., to achieve safety performance And the capacity space is increased, the pressure relief value is prevented from becoming larger, and the effect of reducing combustion and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

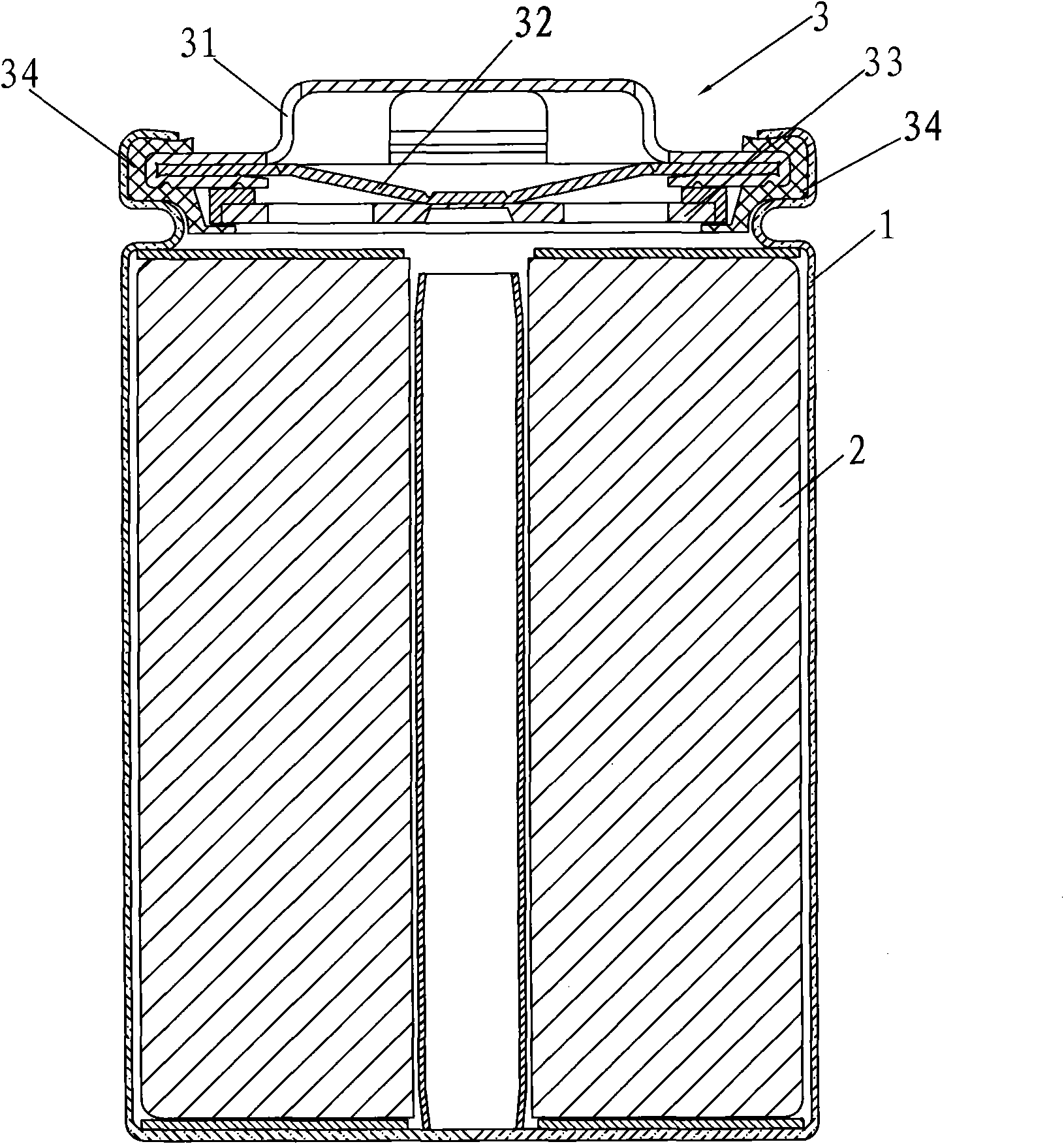

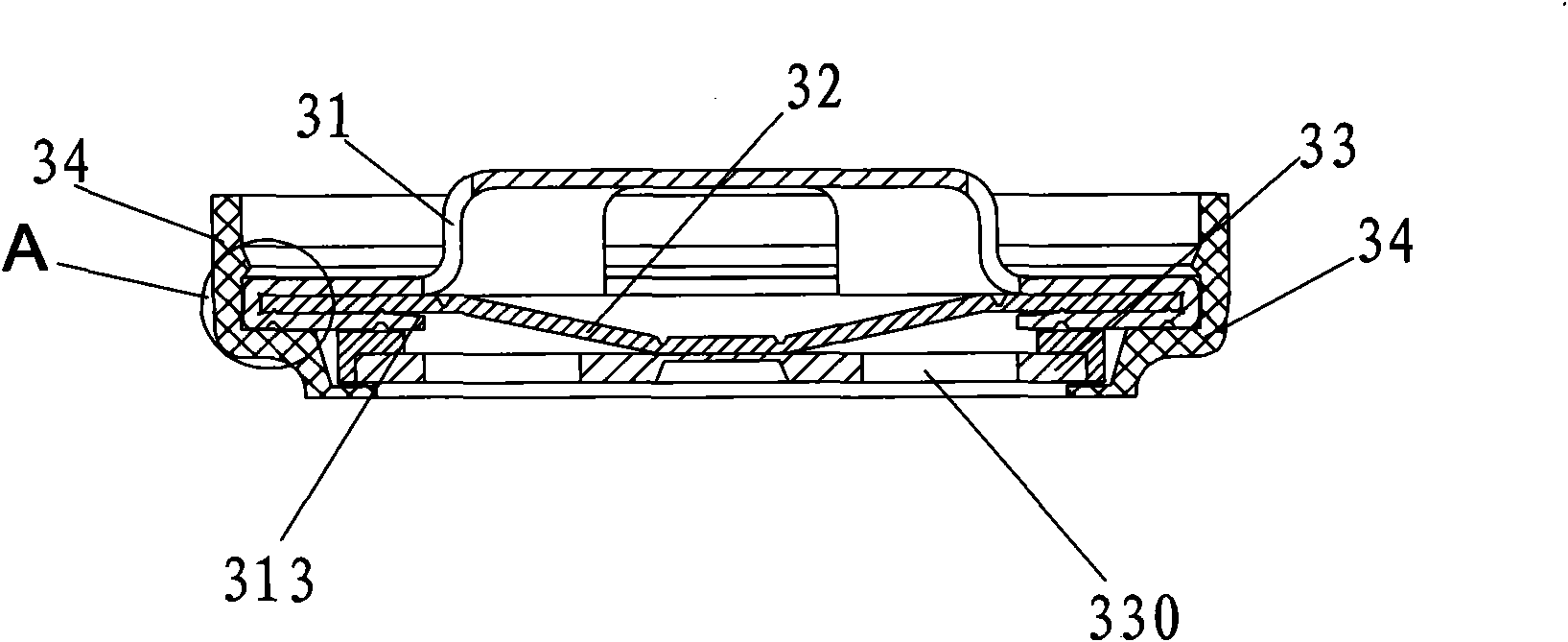

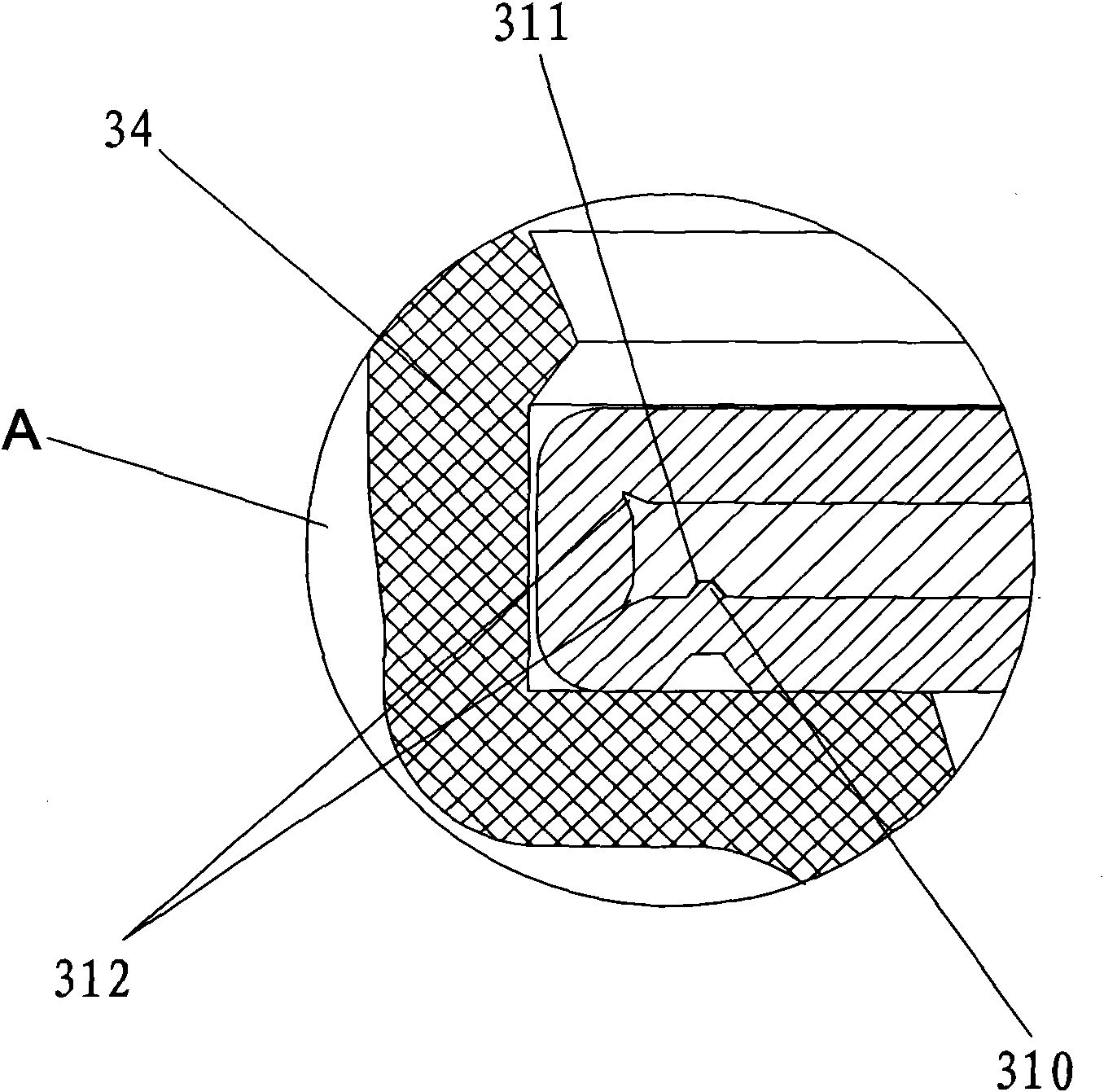

[0020] see Figure 1-3 As shown, the present invention includes: a battery case 1, a pole piece group 2 accommodated in the battery case 1, an electrolyte (not marked) filled in the battery case 1, and a sealed battery case 10 Battery cap3. By folding the top cover 31 in the battery cap 3 inwardly along the edge of the explosion-proof sheet 32 to form a structure covering the explosion-proof sheet 32 on three sides to increase its rigidity.

[0021] Please refer to image 3 As shown, the battery cap 3 includes an orifice plate 33 with an air hole 330 and an explosion-proof disc 32 electrically connected to the orifice plate 330 by welding. When the gas pressure inside the battery exceeds the predetermined pressure, the gas can act on the explosion-proof sheet 32 through the air hole 330 and tear the explosion-proof sheet 32, so as to discharge the gas in the battery in time to prevent the battery from igniting or exploding.

[0022] As an improvement of the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com