Dust removal device of automatic sock knitter

A technology for a dust removal device and a sock machine, which is applied in the mechanical field, can solve problems such as no substantive technical solutions are proposed, and achieve the effects of increasing positioning stability, large contact area, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

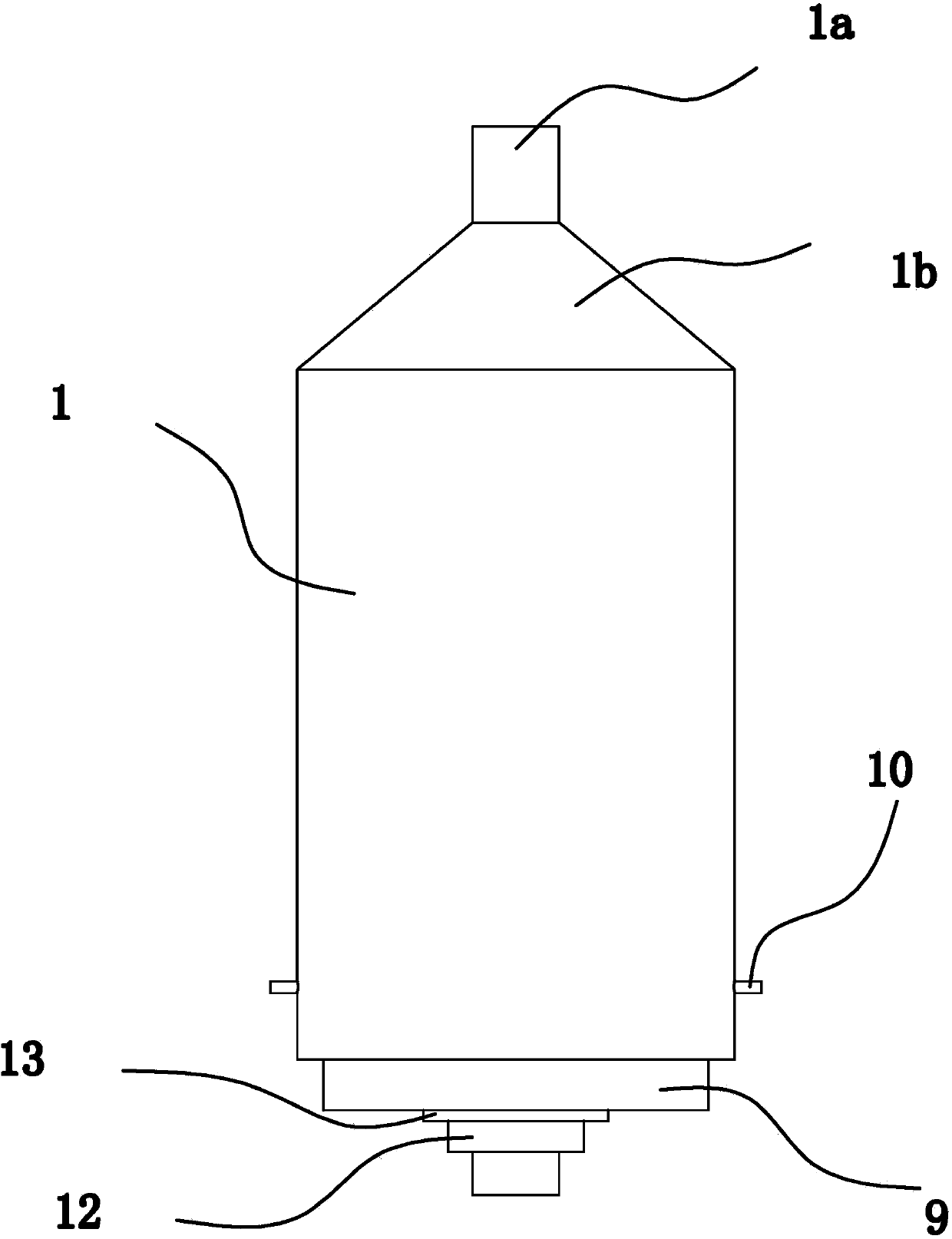

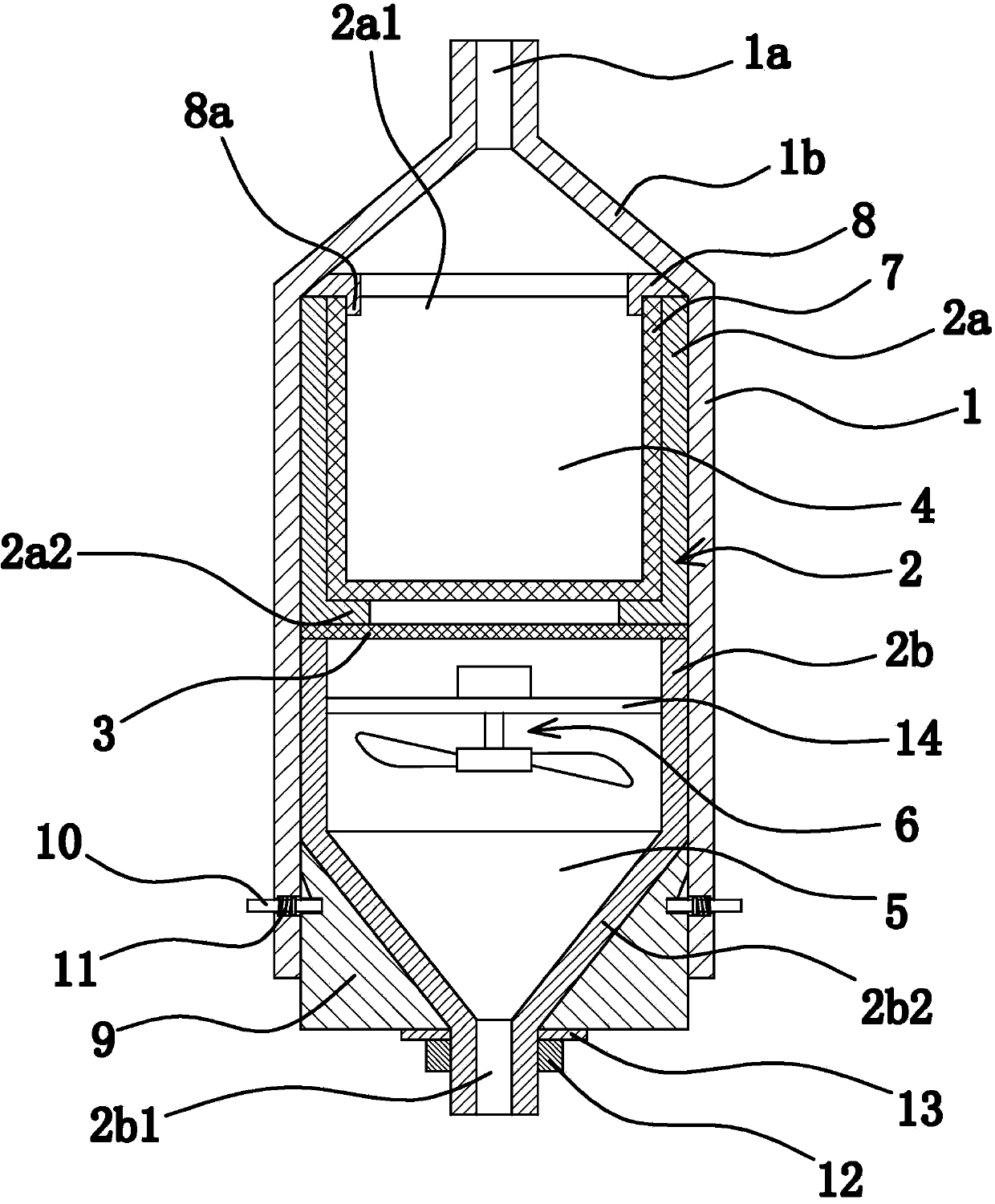

[0046] like figure 1 As shown, the dedusting device in the automatic hosiery spinning machine includes a dedusting cylinder connected to the frame of the knitting machine, and the dedusting cylinder includes an outer cylinder body 1 and an inner cylinder body 2 with a cavity inside.

[0047] like figure 1 and figure 2 As shown, the upper end of the inner cylinder 2 has an inlet 2a1, the lower end of the inner cylinder 2 has an outlet 2b1, the inner cylinder 2b1 is connected with a filter screen 3, and the filter screen 3 divides the inner cylinder into two adjacent cavities up and down : Upper chamber 4 and lower chamber 5. The inlet 2a1 is located at the upper cavity 4, and the outlet 2b1 is located at the lower cavity 5. The lower cavity 5 is also connected with a fan 6 that enables the airflow from the upper cavity 4 to enter the lower cavity 5. The top of the outer cylinder 1 has a The connecting port 1a communicated with the inlet 2a1 has a positioning mechanism betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com