Synchronous cylinder shaping device installed on circular weaving machine

A technology of circular knitting machine and setting device, applied in knitting, setting/stretching endless fabrics, textiles and papermaking, etc., can solve the problems of long process flow, fabric repair or reduction, large equipment investment, etc., to overcome high investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

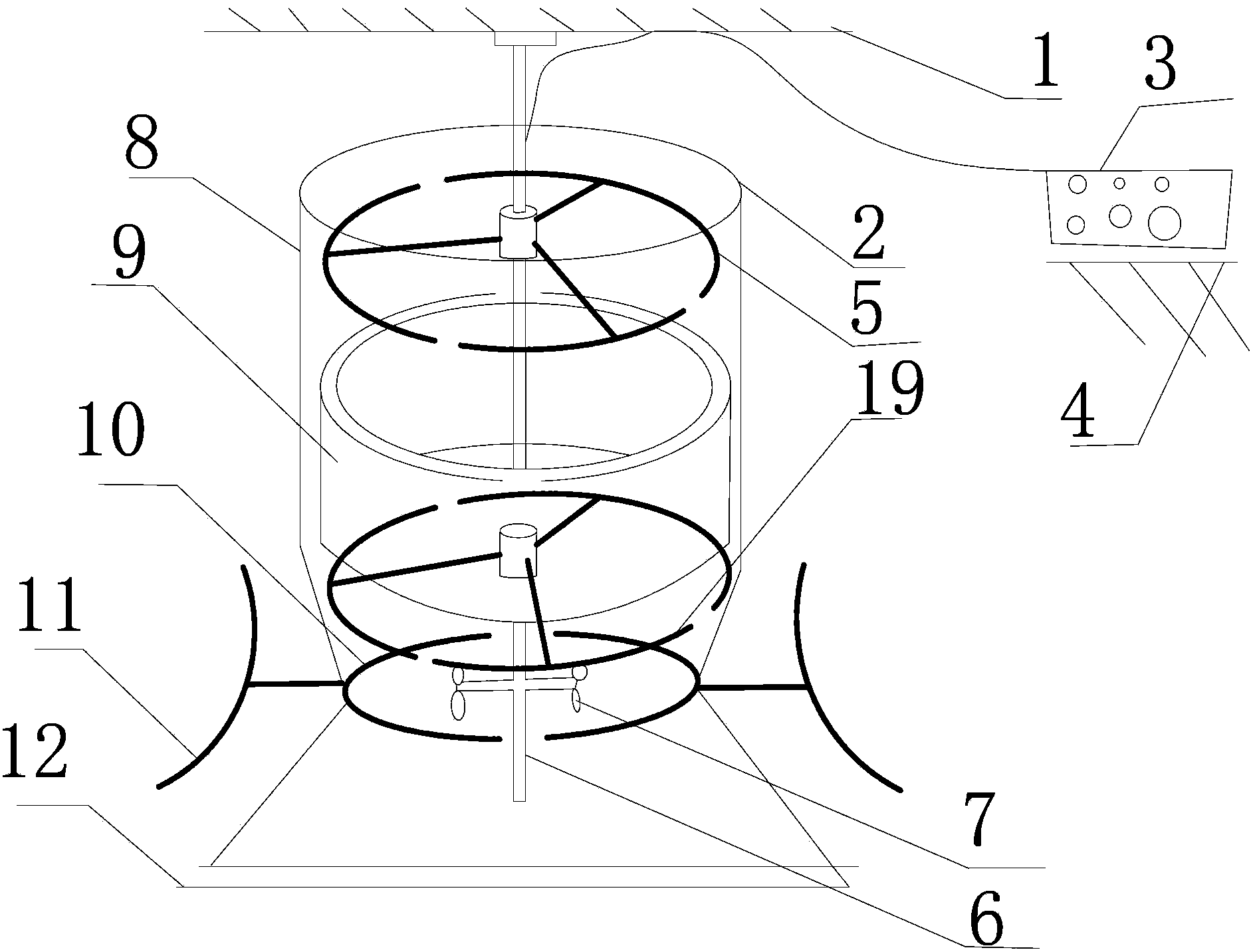

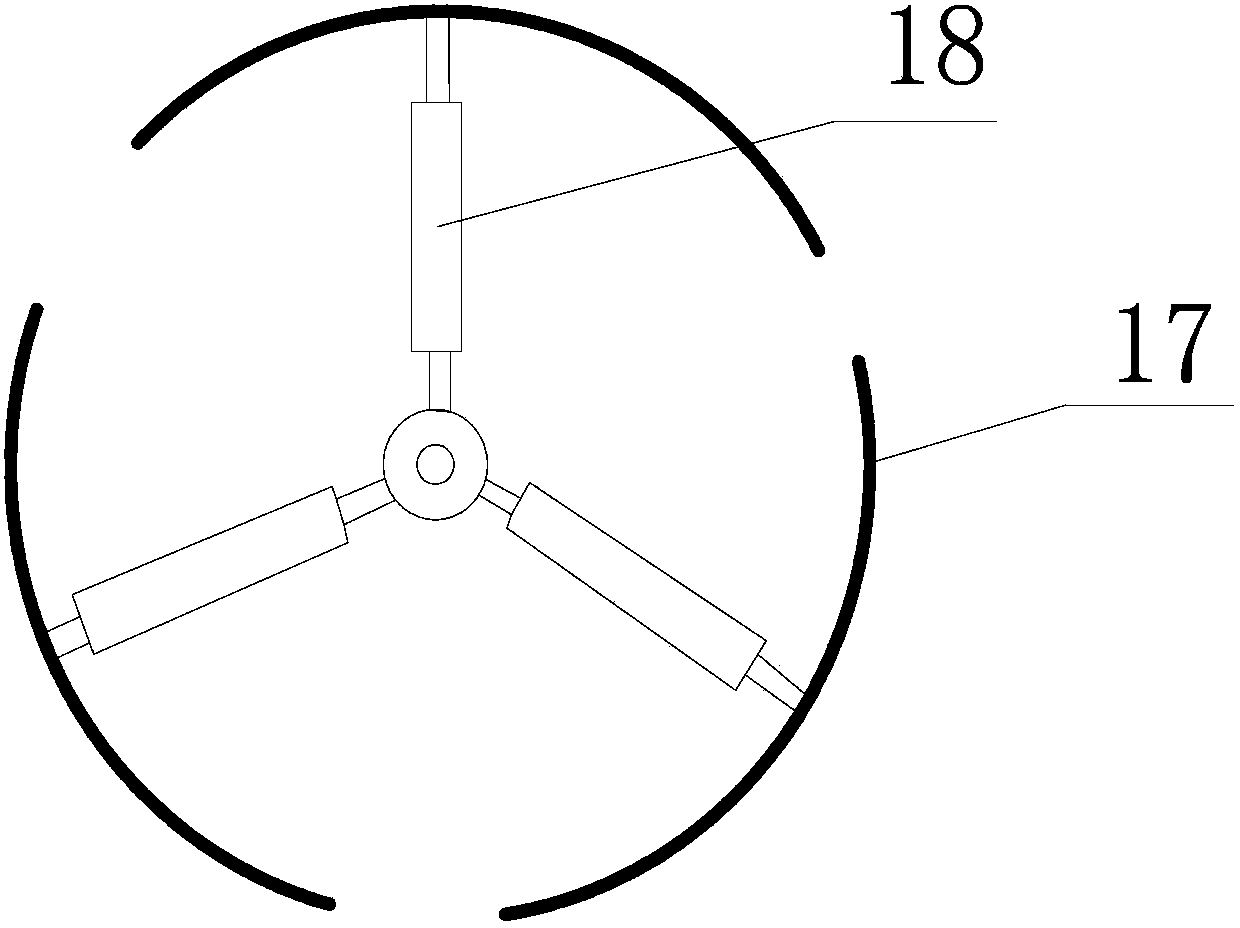

[0022] Such as Figure 1-4 , the cylindrical shaping device installed on the circular knitting machine according to the present invention. Including yarn feeding device support frame 1, fabric weaving starting line 2, control box 3, circular knitting machine table 4, upper pneumatic stretch cloth support 5, lower pneumatic stretch cloth support 19, central vertical rod 6, cooling fan 7, cylinder Knitted fabric 8, high-frequency induction roller 9, cloth receiving half ring 10, pulling cloth driving frame 11, pulling roller 12.

[0023] On the central vertical rod 6 of the circular knitting machine, the upper pneumatic telescopic cloth support 5, the induction roller 9, the lower pneumatic telescopic cloth support 19, and the cooling fan 7 are installed sequentially through sleeves from top to bottom. Cloth-receiving half-circle 10 is installed on the roll-cloth driving frame 11, and cloth-receiving half-ring 10 is positioned between lower pneumatic telescopic cloth support 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com