Online detection device and detection method for knitting needles of knitting machine

A detection device and technology for knitting machines, applied in the field of knitting machines, can solve the problems of frequent shutdown, reduced accuracy, inability to identify defects in fabrics, etc., and achieve the effects of improving efficiency, reducing reject rate, and improving measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

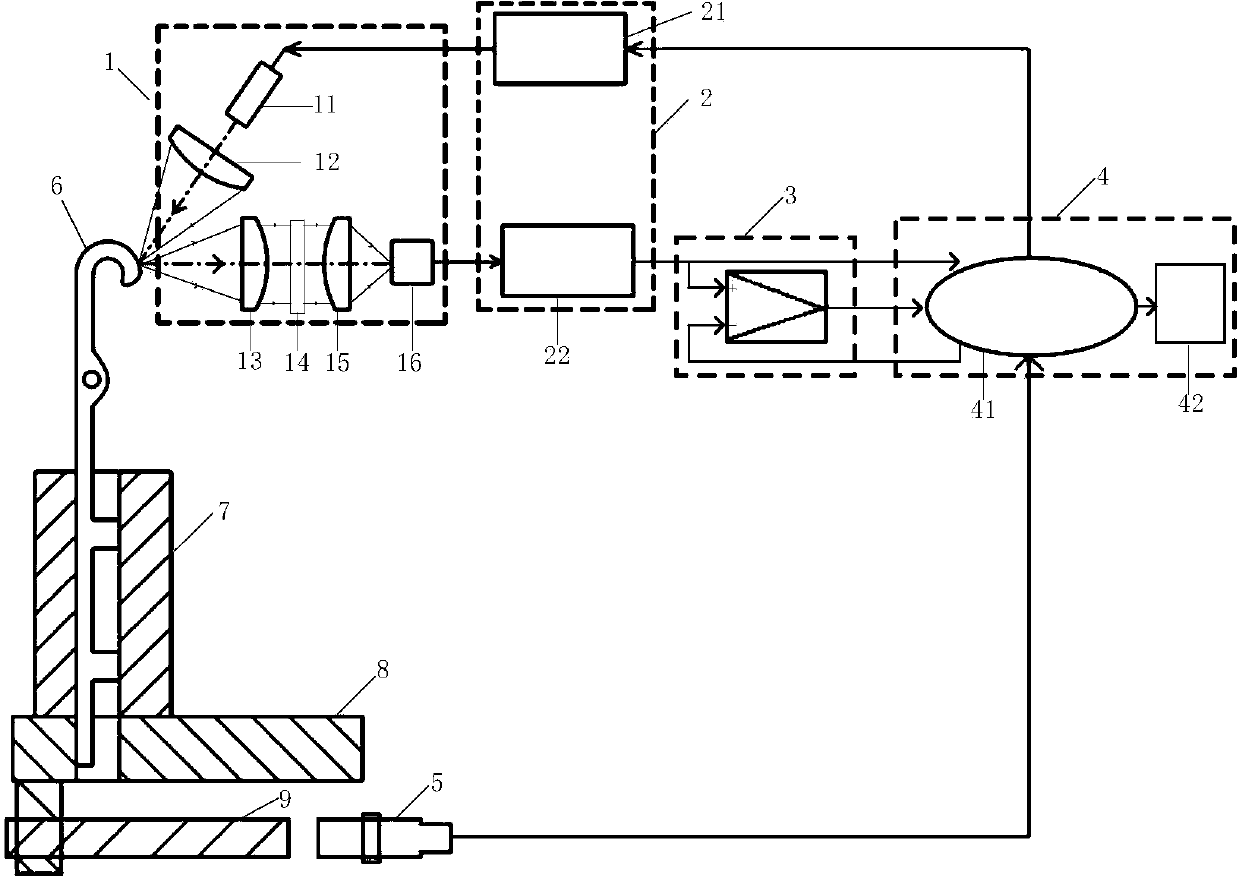

[0041] see first figure 1 , figure 1 It is a structural block diagram of the knitting needle online detection device of the present invention. Depend on figure 1It can be seen that the knitting needle online detection device of the knitting machine of the present invention is mainly composed of a photoelectric sensing unit 1, a modulation and demodulation unit 2, a comparator 3, a microcomputer control unit 4 and a position sensor 5;

[0042] The photoelectric sensing unit 1 includes a light emitting path and a light receiving path, and the light emitting path is composed of a light emitting light source 11 and a cylindrical focusing mirror 12; the light emitted by the light emitting light source 11 is focused on the knitting needle head 6 through the cylindrical focusing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com